By Sandra Thoma

I ordered pancakes, set my menu down, and leaned forward on the table. “How long does it take to remove a cylinder head?” I asked.

My husband Roy, EAA 263467, was seated across from me in a booth in Nancy’s Diner, on the airfield in Willows, California. Our RV-7A, Airstream trailer, and Chevy van were parked outside. Our intention was to head south to be snowbirds and escape the rainy winter in Hillsboro, Oregon, but Roy had discovered low compression in one of the cylinders in the airplane.

Roy grimaced. “Cylinder,” he said. “Not cylinder head.”

Cylinder No. 2 had shown low compression at the recent annual. Only slightly off spec, Roy had said at the time — low 60s over 80 compared to upper 70s over 80 for the other three cylinders. We put the work off while we’d spent the holidays with family in Oakland, but we didn’t want to put it off any longer. Fortunately Roy knew a fellow in Lake California Air Park (68CA), a short drive from the Bay Area, who had the skills and the tools to help get the job done.

“Cylinder. Cylinder head. Same thing,” I said. He’d explained this to me before, but it just wasn’t sticking, and I was embarrassed about it. Airplane engines have cylinder heads don’t they? It was one of those things I felt I should understand about our airplane.

Lake California has an airport and RV park where we could stay in our Airstream while the airplane was grounded. We have friends there I planned to visit, one of whom was giving us space in his hangar. I wasn’t thrilled about hanging there while Roy worked on the plane, and even more embarrassing, I’d grumbled about being an airplane widow.

The thing is, when it comes to working on our RV-7, I usually steer toward the simpler jobs. Sure, outside of aviation I’ve assembled particle detectors and high-energy accelerator components. I’ve repaired an old Land Rover with my grandfather, and I do the annual engine service on our sailboat diesel engine. But none of those things fly in the air above the earth where if things go wrong you can’t just ease over to the side of the road. The fact of the matter is, I find working on our plane intimidating. I’m great at ground logistics, but when it comes to the care and feeding of the plane, Roy does it all.

After breakfast, I hopped in the van as Roy pulled the canopy cover off the plane. Our plan was for Roy to fly the short hop to Lake California, and I’d drive to meet him there. On the drive I watched the dry, grassy hills go by. I must really miss our plane, I thought. It was like I could hear it. I looked up and saw Roy in our airplane, right above me.

Roy and I had recently sold our house and put our furniture in storage, planning to fly the RV Roy built across the country. The Airstream I was hauling behind me would be a basecamp, allowing for our airplane adventures.

Now here we were, Roy flying the plane, and me driving our little silver house down the road. I pictured my husband in the plane without me. Then I pictured him by himself in the hangar working on the plane. It felt lonely. We were supposed to be doing this adventure together.

I thought about this the next morning, too. We had arrived at Lake California and spent the night in our Airstream, and Roy was planning to get up early to work on the airplane.

“I’m going to the hangar with you,” I said, as Roy was getting ready for the day. “I’m going to help with the plane.”

“You are?” he asked. “I can come get you later.”

His offer was tempting. It was chilly outside and the sun wasn’t up yet, but if I went later, I wouldn’t be helping, and I might miss seeing the cylinder taken off the plane.

“I’m going with you,” I repeated. “I’m going to help with the plane.” Most of life, after all, I thought, is showing up.

Pink sky was just beginning to show over the snowy peak of Mount Lassen when we drove to the hangar. It was dark inside, and I could see my breath as rain thrummed on the roof. Roy turned on the lights, then disappeared to search for tools in our van. I rubbed my hands together, blew on them for warmth and looked at our silver plane. I felt like I should be doing something to get started but didn’t know what that something was.

Roy reappeared and opened a box of wrenches.

“Gene will be here in a couple hours, and we have to have the engine ready,” he said. He spoke in a clipped way that let me know he was in a hurry.

“What should I do to get started?” I asked. I didn’t want to break anything or make the work take longer than it needed to.

Roy set up a table in front of the wing and started to take the cowling off. I knew how to do that, so I stepped forward and started helping Roy pull the pins. After we set the cowl on the floor under the wing, Roy picked up a screw-driver and started loosening screws around a large, silver cap.

I knew I could handle that. “I can take those off,” I said.

Roy looked over his shoulder at me, his eyebrow raised. He handed me the screwdriver.

“Here,” he said. “Tilt the valve cover down when it comes off.” He cupped his hand in a lowering motion. “It’ll have oil in it. Got it?”

I nodded. As I worked, I recalled listening to Roy and several of our friends talking about the build process at a fly-in we’d attended recently. I’d heard Roy say, “The airplane is about the person who built it.”

Our airplane was very much about Roy. It is fast, efficient, incredibly capable, and built with a beautiful eye for detail. I’ve been thrilled to be a passenger. Now, I wanted the plane to be about Roy and me. I want the plane to be about us.

I wiped the valve cover and set it on a shop towel on the table. Roy pulled his head out from underneath the engine and stood up.

“Here are the rocker arms and the tops of the valves,” he said. “The valve spring is underneath.”

He pointed out where the fuel goes in, and where the spark plugs are. I wanted to ask questions, but I didn’t know where to start. I knew I was running on the wrong side of “It’s better to ask and sound stupid, than stay quiet and be stupid,” but I just couldn’t work up the courage to get on the right side of that equation. I also knew we were under a time crunch.

“What’s next,” I asked instead.

Roy reached under the engine and pulled out a metal tube about half the length of a Q-tip attached to a bundle of wires.

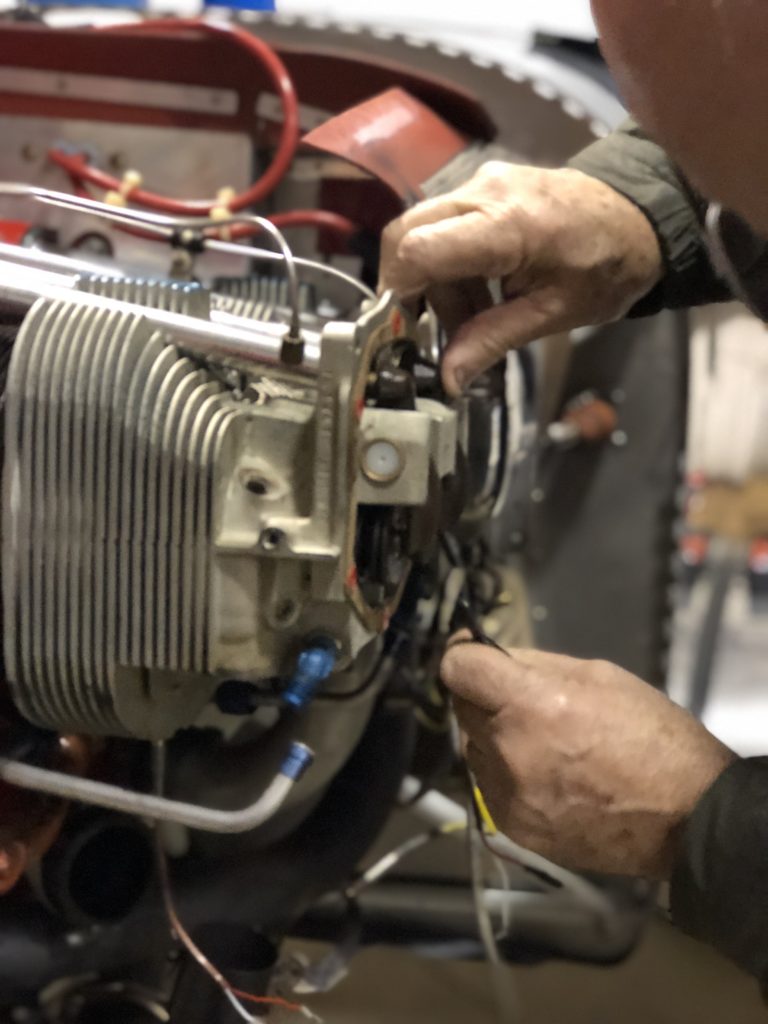

“This is the cylinder head temperature probe,” he said. “The heat shrink has to come off and the connectors taken apart.” He pointed to a razor blade on our work table.

I was picking the wires apart when I heard, “That’s not good.” Roy set his wrench down and picked up a work light and shone it down the pipe. From where I was sitting, I could see cracks in the weld near where the pipe connects to the engine. Just then, Gene walked through the door. Gene is a Ly-Con engine guru who was going to help us with the cylinder.

I left Roy with Gene to take a quick bathroom break, then returned to the hangar.

“You’re just in time,” Roy said. “The tool Gene has to take the bolts off is cool.”

The tool was pretty darn cool. It was a long wrench that angled up and over the cylinder. I watched in fascination as they pulled the cylinder off, exposing the piston beneath. Roy set the cylinder on the table and pointed the work light up inside it.

“Here are the valves,” he said. “One is the air intake and the other, the exhaust. The smooth, shiny part is the combustion chamber.” I felt like part of the cleaning staff at NASA while I listened to my husband. It was a glimpse inside his amazing brain, like I was peering into the room where the space shuttle was being assembled.

Next, the piston had to come off. Roy lifted the head of the piston while Gene tried to wiggle the tube (wrist pin) that connected it to the engine off.

“Not coming off,” I heard Gene say. “I’ll be back.”

To pass the time, I decided to continue the learning session. I pointed to the metal rods on the table. “Are these the push-rods?” I asked.

“No,” Roy said, “It’s the push-rod tube.” The pushrods were next to the push-rod tubes. Next, Roy described the air, fuel, combustion exhaust process, and how the push-rods drive the cams. All the things I had learned before about engines started to make sense. How the engine works became real and tangible. This was the heart of our airplane, dissected here on a card table. Gene came back right as I started to ask about the ignition system. Moments later the piston was off. Gene described how he’d written the CNC machine programming to shave (mill) the piston to make it lighter. He also said the numbers engraved on the piston were the weight so Ly-Con could supply another piston to match the engine if needed.

I held the box open while Roy and Gene slid the cylinder in. I felt all tingly like when I was an intern at the Stanford Linear Accelerator, looking at the detector I’d helped assemble that would capture Z particles. The parts were coming together. I pictured Roy and myself in the airplane together, high in the sky over some desert. When I had questions about how this thing worked or that, I’d be able to mentally put together the parts.

It wasn’t everything. There was tons more to learn, but I couldn’t wait to show up for every bit of it. There was the courage I’d been looking for.

Later that evening we were gathered with some of our friends at the local watering hole. I overheard one fellow say to Roy that he’d seen me at the hangar that day. “So you’ve got her working on your airplane,” he said.

“No,” Roy replied. “She’s working on our airplane.”

He caught my eye and smiled. The airplane is about both of us, after all.

Read more posts on the Tales from the Right Seat blog.