By Vic Syracuse, EAA Lifetime 180848

This piece originally ran in Vic’s Checkpoints column in the June 2020 issue of EAA Sport Aviation magazine.

One night back when I was building time for my commercial certificate, I decided to take a night flight in the Aero Club’s C-172. I was stationed at Davis-Monthan Air Force Base, and night flights were a whole lot more comfortable in the heat of the Arizona summers.

Unfortunately, the battery was too dead to start the engine.With the help of one of the instructors, we jump-started it. After startup, I tried contacting ground control multiple times for a taxi clearance and never got a response. Hmm, must be something blocking the antenna. I started to move the aircraft to get a direct line of sight to the tower. Immediately I noticed that the cockpit lights got much brighter when I increased the rpm. Pardon the pun, but another light bulb went off in my head. So I increased the rpm and finally was able to communicate with the tower. Later, while doing touch-and-goes, I had to maintain higher-than-normal power settings on final and rollout to hear the tower controller’s instructions. I also realized that this airplane had a generator, not an alternator, and generators are not nearly as efficient at producing power, especially at low rpm. I decided I didn’t like generators!

No doubt that experience had an impact on me in my early flying days, as I caught a couple of in-flight electrical system failures before they caused serious trouble. It also caused me to focus on building robust electrical systems in the 11 aircraft I’ve built. It has paid off — I have never had an electrical failure of any kind in them, and only had to jump the battery a couple of times due to having left the master switch on.

However, I can’t say the same robustness is there in many of the electrical systems I see in the amateur-built aircraft world. It’s really no surprise, because the majority of the kits leave the electrical system details up to the builder. Quite honestly, even the certified airplanes I’ve worked on over the years have some convoluted electrical systems in them due to all of the changes over their 50 years of life by A&P mechanics who clearly didn’t understand electrical systems either.

I am a firm believer in simplicity when it comes to electrical systems in airplanes. I know that will go against the thinking of those who feel a need to have multiple batteries and multiple buses with diodes separating them. Perhaps there was a time for each of those in the past, when for some reason all of the engine instruments were usually installed on the far side of the cockpit, out of the normal vision of the pilot. That kind of instrument layout would cause the best of pilots to miss that the ammeter had gone from a slight positive charge to a negative charge, with recognition coming as the radios slowly got quiet as the battery no longer had enough energy left in it to allow the radios to receive, let alone transmit. With today’s glass cockpits, and all of the available warning annunciators, I think there is a need for redundancy in only a couple of areas, and that is based upon experience.

I see many airplanes come through our shop with absolutely horrible electrical systems installed in them. Some even take me a while to figure out, especially those with unlabeled switches. Others seem to be designed to give the builder some kind of false sense of security. As an example, I have seen aircraft with dual electronic ignition systems having a backup battery that would never work if it was really needed because it was never properly connected to the charging system or routinely tested. Yes, a critical backup battery should have a way to be routinely tested prior to every flight, especially in the above-mentioned case with dual electronic ignitions systems that require battery power.

I am not going to try to design an electrical system for you in this column. There are many good sources of material already out there to help you with that. I would like to highlight a couple of areas that I find to be the most problematic, unnecessary, or unreliable.

I think the majority of builders out there have had the same experience with a dead battery that I did, and now, with all of the electronic gizmos in the cockpit, there is a real fear of the battery going dead at the worst possible time. I understand that line of thinking, especially for those of us in my age bracket. We still remember our childhood days and how all of the flashlights’ batteries or bulbs were dead every time we went to use them. If they did light up, it seemed as though they had about 2 candlepower of lumens! Does anyone remember flashlight tag? Most everyone carried jumper cables in their cars, too.

My, how things have changed! Now we carry a flashlight in our pocket that uses a single AAA battery instead of two D cells. Some even seem bright enough to light up the moon on a dark night! Yep, battery technology and reliability have improved drastically during the last generation, and these improvements have found their way into aircraft as well. Most of the batteries installed in our airplanes today are no longer the messy lead-acid batteries of yesteryear, but are absorbent glass mat or even lithium, both of which are maintenance-free and can provide many years of trouble-free service. Some can sit for up to a year and still start the engine without a jump-start.

So, that begs the question: Why should I carry two of them if they are so reliable? In a vehicle where weight is everything, carrying two 20-pound batteries is really detrimental. (In the case of dual electronic ignition that may require a power source, the second battery can be substantially smaller, of course.)

But, if you decide to install two batteries, have you made certain they are installed in such a way as to properly charge? Are the aircraft switches clearly labeled as to how to use them? In one example in an aircraft with two batteries and two master solenoids, they used the second full-sized battery to help with hot starts through the use of two master switches. Once that second master switch was deactivated, the second battery was disconnected from the aircraft’s charging system and, over time, it slowly died due to incomplete charges.

The reality is that a battery rarely fails anymore, especially if it is properly taken care of, meaning it is properly connected to the charging source in the aircraft and is not mistreated by being constantly left on a nonapproved battery tender/charger between flights. If your battery seems to be weak after a couple of weeks of not flying, I would bet you have something in your aircraft that is wired to the hot side of the battery and is slowly draining it. I have seen it multiple times, with the repeat offender being the 406 ELTs that require a 12-volt connection.

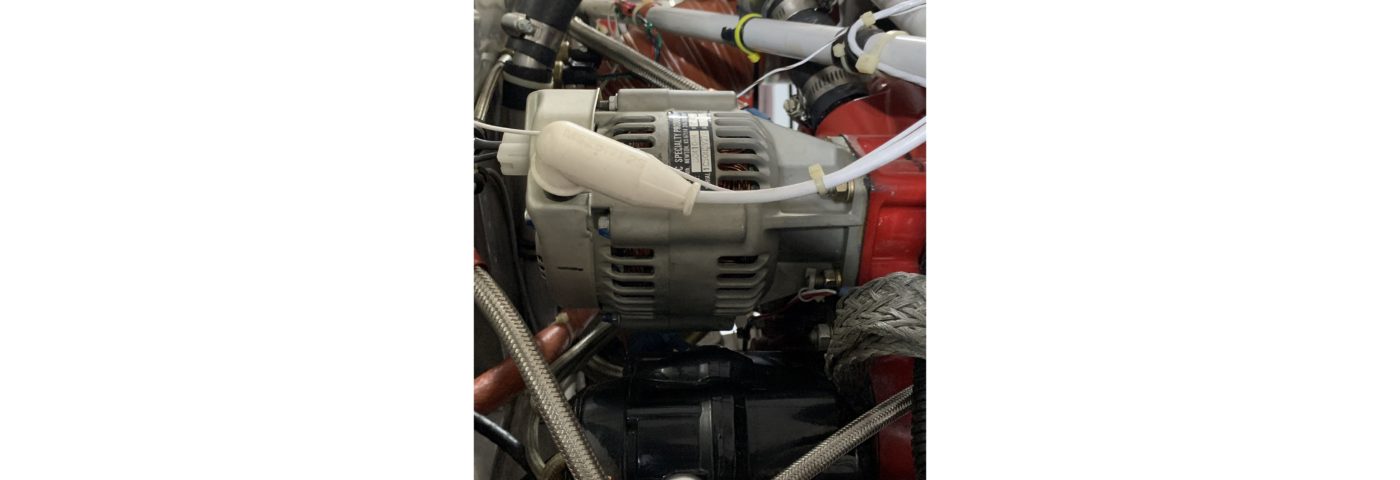

Alternators these days are also reliable, much more so than the generators of yesteryear. So, why not lose that second battery and use that extra available weight for a second backup alternator? You’ll still have weight savings, and the second alternator won’t limit your flight time should the main alternator fail. I’ve had one on many of my airplanes and installed them on many customer airplanes. I have needed it only once, due to a regulator failure, and it got me through eight hours of flying with five stops. For IFR flying, I think it is one of the best investments you can make to increase the electrical system reliability. As an added plus, if your main alternator ever fails at some out-of-the-way airport on a Sunday evening or similar scenario, the backup alternator will get you all the way back home where you can address the problem on your time. Modern backup alternators are capable of 30-40 amps, which is a comfortable buffer for even the best-outfitted glass panels. During the installation, the backup alternator can be wired so that it comes online automatically in case of a main alternator failure, with a warning light informing you it has been activated.

Another area that causes problems is not understanding how critical it is to properly size the wires. The largest wire in the system will be from the main battery all the way through the solenoids to the starter. This is usually a “0” or “00” gauge wire. It is super important that the ground wire from the battery to the airframe and from the airframe to the engine is of the same size. I see way too many installations where the ground wire is the same size as the alternator wire, which is horribly wrong. A starter can draw 200-300 amps when energized, hence the need for a very large wire. Most alternators are 40-60 amps, which only require a 6 or 8 AWG wire, which is substantially different than 00. Since a 6 or 8 AWG can’t carry 200-300 amps, guess where all of the rest of the current flows? It goes through every other metal or wire connection to the engine, such as engine control cables, shields on shielded wires, etc. Undersized grounds make for slow-turning starters, which everybody initially thinks is a battery problem. Don’t get fooled.

I also believe it is important to use high-quality aircraft alternators, good Tefzel aircraft wires, and the proper crimping tools for the connections for increased reliability.

In a nutshell, consider losing the second battery, add a backup alternator, and check those grounds. It will keep the fun factor alive. I assure you it is no fun to come back to the airplane with the family on the last day of that vacation trip and hear dead silence when the key is turned.

Vic Syracuse, EAA Lifetime 180848 and chair of EAA’s Homebuilt Advisory Council, is a commercial pilot, A&P/IA, DAR, and EAA flight advisor and technical counselor. He has built 11 aircraft and has logged more 9,500 hours in 72 different types. Vic also founded Base Leg Aviation and volunteers as a Young Eagles pilot and an Angel Flight pilot.