By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the November 2020 issue of EAA Sport Aviation magazine.

“I’d really like to have metal covers on those tanks.”

“Do you realize that metal covers are not what came on the airplane? The cover on the tanks is fabric,” the restoration shop owner said.

“But I saw an airplane with metal, and they look really great,” Frank said.

“They do look great. Let me research it and see if I can find an STC (supplemental type certificate) or previously approved data for it.”

“That would be excellent. After all, when you’re rebuilding an antique, you might as well have what you want.”

Michael watched his most demanding customer walk out of the shop. He shook his head and turned to Roger, who was working on the brake assembly of the 1942 Stearman.

“I want more than anything to please my customers,” Michael said. “But they don’t realize sometimes what they are asking for. I have to keep this aircraft legal as I rebuild it. If I can’t find approval for metal covers somewhere, then I’m looking at an alteration that will require a DER (designated engineering representative). Add possible flight testing and the cost of the engineer and it all adds up.”

“And we wonder why our customers keep saying it’s all too expensive,” Roger said.

“Research. Let me go do some research.”

* *

On the other side of the field, at Ed’s Aircraft Repair, a different discussion was underway.

“A guy just walked in here and asked me if I can make and install metal covers over the fuel tanks in his airplane.”

“What did you tell him?” Sally asked.

“I said sure,” Ed said. “Why not? How hard could it be? Maybe it will add a little weight.”

“Okay. Well, we’ll see if he brings us the airplane.”

* *

Back at the restoration shop, Michael was checking for STCs on Stearman metal tank covers. Not finding anything, he called Bill, an engineering friend who is also a DER.

“Send me some center section drawings and how you propose to install the cover,” Bill said. “I’ll come up with the cost of the engineering and get back to you in a week or two. Once you have all the data, then you can do the 337.”

“Ah, okay, Bill. Thanks for the roadmap. I think I’ll talk the customer out of it.”

“Good luck.”

* *

Across the field at Ed’s, the phone rang.

“Ed, this is Frank. I’ll have the airplane to you next month when it gets out of the restoration shop. How fast can you do metal covers?”

“A week or less.”

“Great.”

* *

If an aircraft appears airworthy, is it also legal?

Not always.

Here are the top five areas where “paperwork” was omitted or regulations unwittingly skirted. These examples are based on my experience as a mechanic and as a technical counselor. I’ll bet our A&P mechanic readers have some interesting stories, too.

Ultralight Vehicle

I received a call to visit a project. On the phone, the owner said it was “an experimental vehicle, probably an ultralight.” This did not sound reassuring to me.

When I arrived at the hangar, I saw what seemed to be a typical single-seat ultralight, looking like an Aerolite 103. The engine appeared out of place due to its size.

“That looks like a Rotax 582,” I said.

“It is,” the owner said. “This thing really flies!”

“You’ve been flying?”

“I sure have. I’ve got a top speed of 70 knots — and that’s with adding a second seat.”

Already confused, I became even more confused when I looked carefully at the structure and saw a second smaller seat behind the front seat with no belt or harness. I closed my eyes and reopened them, hoping I would see something different.

“I took parts of airplanes from all the fly-ins and made my own flying vehicle. It only weighs 270 pounds so it’s close enough for an ultralight, which everyone says you don’t need to license.”

To make a long story a little less long, we sat down at a table in the hangar while I explained that an ultralight had to be 254 pounds or less, have a top speed of 55 knots or less, and have a single seat. He had no idea. He thought that “close enough” would be just fine with the FAA.

This story ended well with a complicated but successful conversion to an ultralight.

The lesson here is to know the regulations for whatever aircraft you’re building or flying. In this case, the aircraft was flyable but not airworthy or legal.

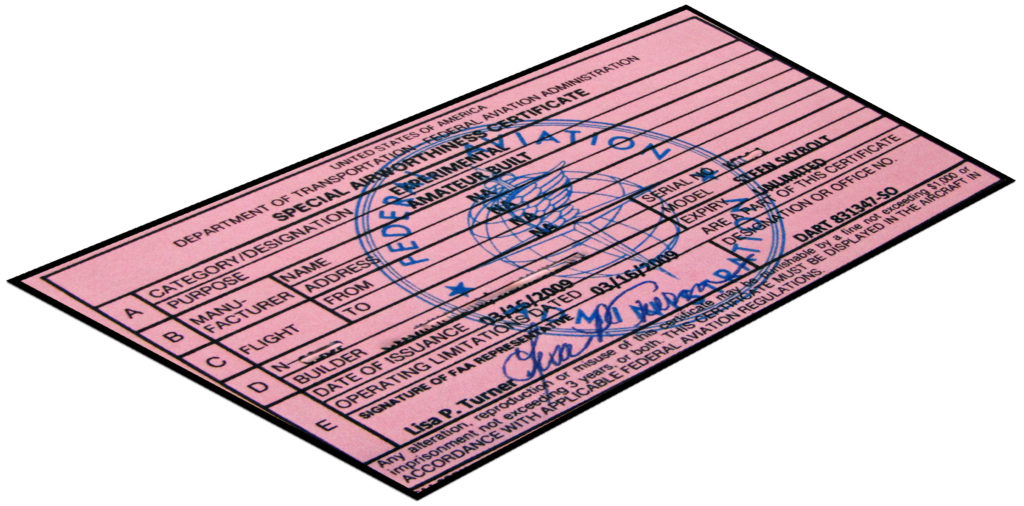

Light-Sport Aircraft

A question I get all the time is, “If I have a special light-sport aircraft (S-LSA), can I add extra stuff to it?” In one case, the question had to do with gadgets and electronics. While the items sound straightforward, it’s actually against the regulations to modify your S-LSA in any way. If you own an S-LSA, you can contact the manufacturer (factory) and get approval for what you’d like to change or add. Most minor alterations or additions can (and do) get approved. To keep the special airworthiness certificate, the aircraft must stay in its factory configuration and be professionally maintained.

The next question may be, “But, what if I really want to maintain it myself?”

No problem. Simply exchange the special airworthiness certificate for an experimental certificate. An experimental light-sport aircraft (E-LSA) can be modified and maintained by the owner. If you want the flexibility of doing your own maintenance and inspections, adding accessories, and making minor modifications, you can obtain a light sport repairman certificate with an inspection rating, which is a 16-hour class for owners.

The lesson, once again, is to know what you’re flying and what regulations pertain to it.

Experimental Amateur-Built

The top regulation-related deficiency that I’ve seen repeatedly is owners adding items and making major changes to the airplane after getting the airworthiness certificate. While adding gadgets and avionics is not such a big deal if it does not change operational characteristics, making structural modifications can present problems.

During one prepurchase inspection, the seller turned to me, pointed behind the seats, and said, “See that 8-gallon fuel tank? That one modification really added range.”

“I imagine it did,” I said. “The factory had no problem with that going there?”

“The factory? Oh, no. I don’t think they would have approved that. I did it after I got the airworthiness certificate. My friend across the field asked before I did, and the factory engineer said it would alter the handling and weight and balance too much.”

“Aha,” I said as I put a big X at the top of the buyer checklist page. I made a note to myself to circle back around and have a private discussion with the seller on best practices.

Many E-AB owners firmly believe that there are no regulations or limits to what they can do. It’s a surprise when we pull out the operating limitations and determine that their “improvement” needs to be approved.

The lesson learned here is that even though your airplane may be an experimental amateur-built, that doesn’t mean you can make major changes to it and still fly safely. If you want to make a major change as you build, contact the manufacturer and let it help you determine how to do what you want safely. If you want to make a major change after you’re flying, get advice. Your designated airworthiness representative, FAA inspector, and the manufacturer are good places to start. The process for approval may not be as bad as you think.

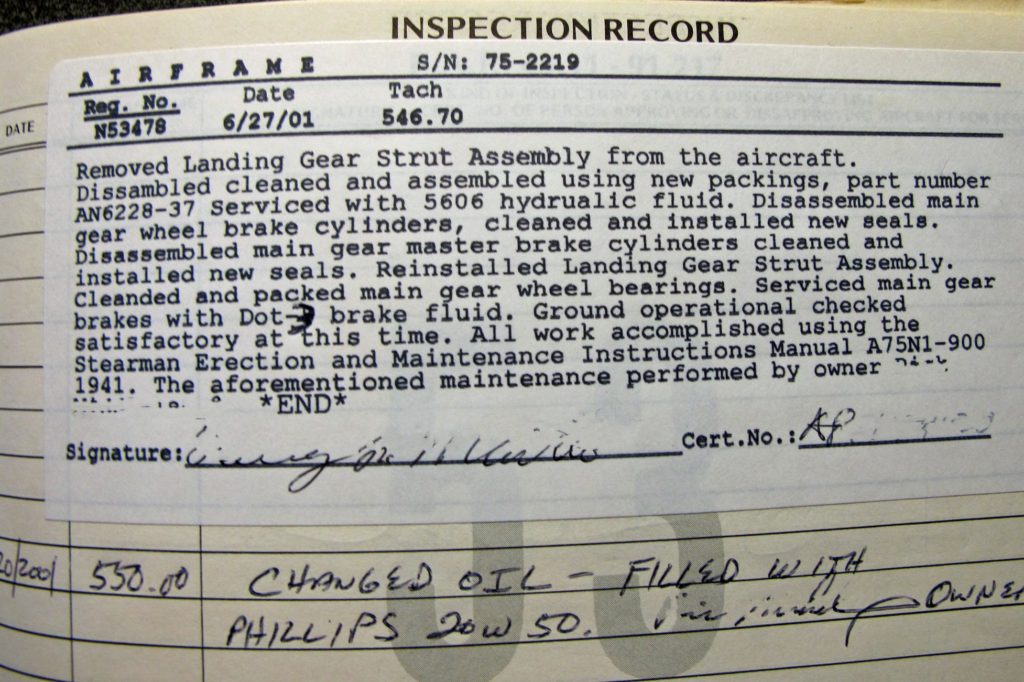

Certified Aircraft

It’s a little harder to go off the rails, at least paperwork-wise, with certified airplanes because most of us take them to shops with A&P/IA mechanics who fill out the paperwork (with the majority doing a great job). The biggest paperwork gotchas are mechanics not being thorough when filling out the logs and a pilot’s operating handbook out of revision or one that actually belongs to another aircraft.

Certified aircraft also suffer from the “it’s just a little change, it should be okay” mentality as the owner installs new upholstery that he or she likes from the auto parts catalog, not realizing that nearly everything in a certified aircraft has to be FAA approved.

The lesson learned in this case is that if you want to make a change or addition, get advice from an A&P/IA before proceeding.

Classic and Antique

This category should be plagued by the same errors that we see in the newer certified aircraft category, but that’s not the case. Owners of older aircraft are typically more thorough on paperwork. The problem we see is noted in the story I launched with — a misunderstanding over what modifications can be done and the paperwork that has to accompany it. We’ve been surprised at how many normally conscientious owners “look the other way” when told they need proper documentation.

The lesson here is that a change or addition may not be as complicated or expensive as you think. Not doing it by the book, however, could end up being very complicated and expensive at inspection or sale time, or if you have an accident.

Takeaways

An airplane that appears airworthy may, in fact, not be airworthy. As the owner of your aircraft, it is your responsibility to make sure that all the details are understood and the documentation is correct and up to date. But this may not be easy. Here are some tips.

Service Bulletins and Letters

Owners of all aircraft should pay close attention to service information from the manufacturer. The factory took the time to issue it for a reason, and it’s usually safety-related.

Airworthiness Directives

Airworthiness directives (ADs) are legally enforceable regulations issued by the FAA in accordance with 14 CFR Part 39 to correct an unsafe condition in a product. Part 39 defines a product as an aircraft, engine, propeller, or appliance.

I hear from owners of experimental aircraft is that “ADs don’t apply to anything on my airplane because it’s experimental.” As a conscientious pilot, do you believe in flying as safely as you can, especially when others are flying with you? If the answer is yes, then my response is to check for and comply with any AD that applies to anything in your aircraft. That includes the engine, avionics, propeller, fuel pump, etc.

How does the FAA feel? The regulations state that the owner-operator is responsible for maintaining the aircraft in a condition for safe operation. If an AD is applicable, how can your airplane be safe without complying with the AD?

Changes and Alterations

It’s not my intent in this article to advise you on how to navigate the regulations, but rather to alert you to the importance of them.

Practically speaking, if you have a certified aircraft and you’re not an A&P, then you should consult with an A&P/IA on changes you want to make. You may not be happy with the A&P’s answer, but do you want an airplane that is airworthy? The regulations are there for a reason, as upset as we can get with them.

If you’re the owner of a homebuilt, then pull out the operating limitations (a copy is in your airplane, right?) and read the fine print on changes. It might say that a “minor change” is one that has no appreciable effect on the weight, balance, structural strength, reliability, operational characteristics, or other characteristics affecting the airworthiness of the product. It likely also tells you that anything other than a minor change needs approval from the FAA inspector or DAR, along with an airworthiness review and reauthorization.

Documentation — Logbooks and Records

Don’t brush off or neglect filling out your logbooks or other record-keeping duties. “I’ll do it later,” turns into “Oh no! I forgot to put that in the logbook.”

When you get your aircraft back from service, check the documentation and logbooks to make sure all of the service was entered correctly in the records. If you don’t, and something is missing, it could come back to bite you later. It is our responsibility as owners to ensure that all the documents are available and correct.

Bottom Line

Some owners approach paperwork as an afterthought. There are two good reasons not to. The first is resale. I have seen many beautiful airplanes not pass their prepurchase inspection for lack of correct and up-to-date records. And the second reason is the most important: safety. When you comply with the paperwork requirements, you will typically have a safe and airworthy aircraft.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former DAR. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at www.DreamTakeFlight.com. For more from Lisa, read her Airworthy column each month in EAA Sport Aviation.