By Ian Brown, Editor, Bits and Pieces

From the January 2021 issue of EAA’s Canadian newsletter, Bits and Pieces.

Van’s RVs have a very nice canopy system but it’s not that easy to remove quickly. One aspect that is somewhat cumbersome is attaching charging leads to the battery. In my case the battery is on the left firewall but the oil inspection hatch is on the right. It’s impossible to reach in to connect battery charger leads.

A neat trick that I learned from another RV owner was to take a short extension cord and cut it in half. Use half to attach to the battery, the half with the socket on it. You can attach the other half to your battery charger with appropriate connectors then use the plug end and the socket end to connect to each other. The extension cord can be attached to the engine mount and led out to somewhere accessible near the oil inspection hatch. That’s what I did and it worked well for many years.

Recently I started up my engine and, while the engine seemed to be running fine, the analog instruments in the panel all started jumping around wildly. I had no idea what was happening but knew that I had something dramatic happening with my electrical system. Was it a grounding problem behind the panel? Was it a voltage regulator failing?

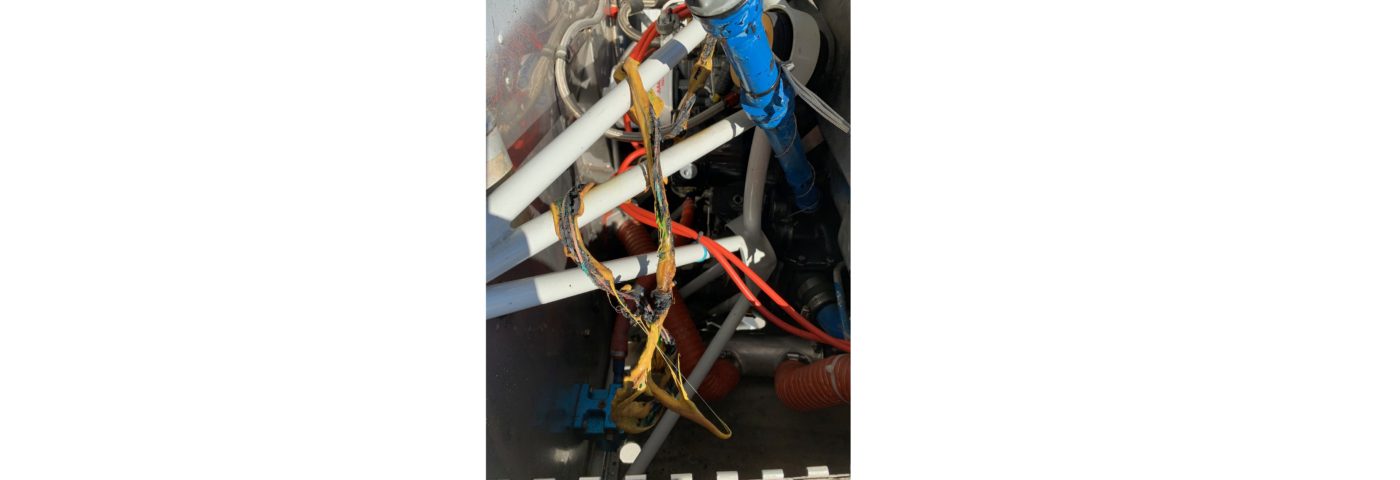

Being pushed for time, I put the aircraft in the hands of my local maintenance shop. I heard nothing for about two weeks except for a scary photo in a text message, which at first glance made it look like the whole wiring harness leaving the engine and passing through the firewall had burnt to a frazzle. This was definitely OMG time! In my mind I was thinking how many hours at $100 or more it would take to fix the problem. I spent two weeks thinking I was going to get a bill for maybe $5,000 for the repairs, especially since RV’s don’t exactly come with a standard circuit diagram.

Imagine my relief when I finally received a call explaining that what I was looking at in the photo below was my extension cord burnt out and not my wiring harness. The jumping of my gauges seems to have been due to intermittent shorting of the battery positive to ground.

Apparently it had somehow managed to short itself to the engine mount making my battery dump current through the cord until it melted and burnt out. My mechanic explained that it had only taken two hours, maybe three to fix and that everything was working normally. The battery seemed fine and no further damage was visible.

Lessons learned:

- Do not use an extension cord. It can carry too much current.

- However you run an extender, make sure it’s not directly touching the engine mount (a perfect ground), but ty-wrap stand-offs so it’s held away from the ground, or add extra insulation where you attach it.

- As an item on your checklist, check for a clean separation and no fraying each time you have the cowl off. In fact, take the cowl off after maintenance by others and check everything visually.

- Always pull the cowl off and check visually if you’ve had any work done by anyone else.

I had some repairs done by another mechanic that included some welding because of galling from the exhaust system, but it’s still not completely clear to me how this happened. I just thought it was worth sharing so that you might not have the same problem.