By Vincent Homer, EAA 162674

With the help of several members and a scissor lift courtesy of Henry Bartle, EAA Lifetime 168984, my collection of three World War II mock-up cockpits were hung in front of the sky mural painted by Kristin Taylor, EAA 1281613, and her father, on EAA Chapter 292’s hangar wall. We will eventually have a descriptive plaque mounted in the area telling the story of each aircraft and the project.

I started this project in 1999 when I decided to build a 70-percent mock-up of a P-39 to see if a homebuilt version of this aircraft was possible. At the time I was working in Saudi Arabia and when I left, the company shipped it back along with my household stuff. To get this to happen I told them it was a “sculpture” of considerable value. Since arriving back in the U.S. the P-39 has hung from several of my shop ceilings.

For reasons I’m not entirely clear on, last year I decided to build a 55-percent German Me 262 jet cockpit and later a 50-percent version of a B-25 Mitchell medium bomber. Both of these were made of corrugated cardboard and some wood. I mentioned to David Ullman, EAA 446096, that I was planning on hanging the B-25 so it looked like it was flying out of the west wall of my hangar. The floor space in my hangar has long since been covered up necessitating all the mock-ups be hung from the ceiling. David’s comment was, “Why not hang all of them on the east wall of the EAA hangar?” The chapter board agreed and Kristin was recruited to paint the sky on the wall. Mock-ups of the mural were built to give people a hint as to what it would look like. While not entirely convincing, it helped convince the board to give the go-ahead.

Bell P-39 Airacobra (70-Percent Scale)

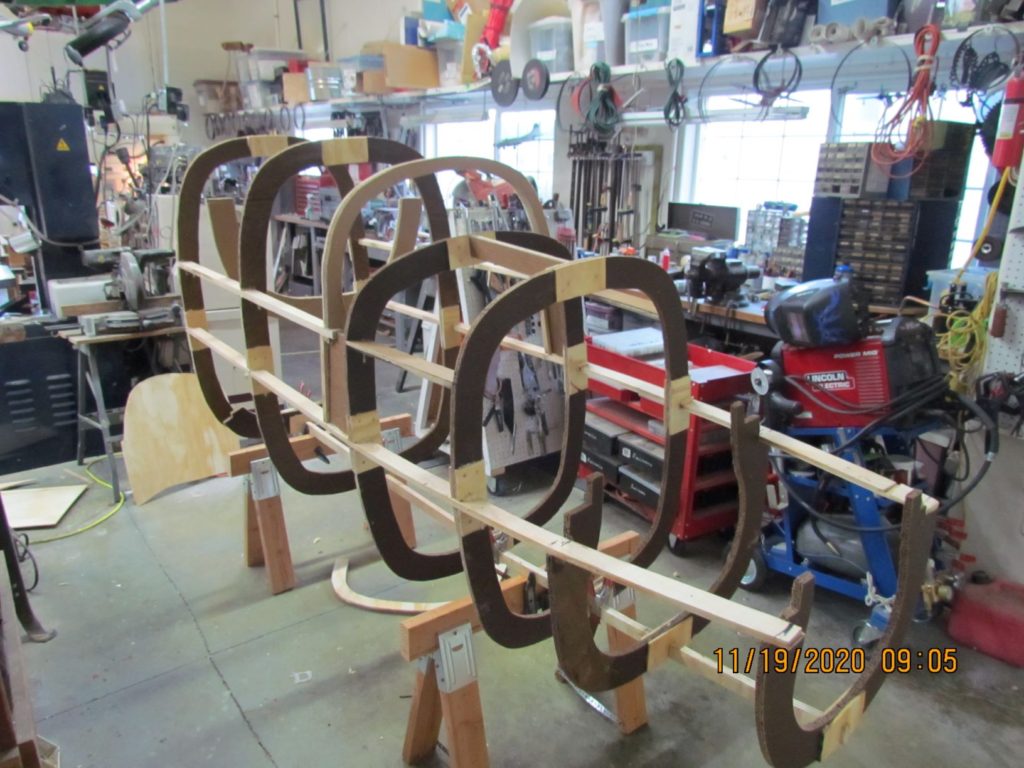

This mock-up was built as a frame-only version with a representative cockpit interior as a study for a homebuilt aircraft. A giant-scale RC model airplane plan set was enlarged from 20 percent to 70 percent to make patterns for the bulkheads, ribs, etc. The fuselage was assembled with a rotisserie and completed to the frame only stage. Mock-up internal parts such as the engine, drive line, instrument panel, seat, and controls were installed. This aircraft has automobile style doors that were also made. The parts for the center section were made and assembled two years ago. To complete the mock-up for the mural, the right side of the frame was covered with RAM board, a cardboard product used in construction. The paint scheme is from North Africa early in WWII. Water-based house paint over KILZ primer was used and lightweight wallboard spackle filler applied as needed.

The covering process consisted of priming both sides of large sections of RAM board and when dry, painting the one side chromate color. Smaller, fitted pieces are cut from the prepared RAM board, a bead of Gorilla Glue run around the supporting structure and stapling the RAM board to the structure. Gorilla Glue should be used sparingly to avoid big glops of foam that have to be removed. Once the glue is cured, the staples are removed and the holes filled with lightweight spackle compound.

Messerschmitt Me 262 (55-Percent Scale)

This mockup was prompted by the question, “Could one build a scale Me 262 (or other jet) using ducted fan propulsion?” The 55 percent scale chosen was, unfortunately, too small. Something like 65 or 70 percent would have been better. I can get in the cockpit, but it is too confined to be practical as a flying aircraft.

The construction of the Me 262 was about half double wall corrugated and half plywood and 1/4-inch by 2-inch stringers. The same RAM board covering was used as was a KILZ primer. The color coat was spray can camo paint. A limited cockpit interior was installed in this model. Similar to the other mockups, the nose gear was fabricated from PVC pipe and the wheel from an inner tube wrapped with friction tape and covered with vinyl spray-on coating.

Finishing the original mockup involved adding the nose and nose gear and stub wings. The hanging eyes were also reinforced to support the extra weight due to the improvements. The forward eye was also moved further forward to compensate for the added weight of the nose and gear. The original version ended at the “Z” and the complete nose was added along with the nose gear and removable transport wheels for the mural. Canopy glazing was also added to complete the model. Adding the engine nacelles and main gear would have been too big to fit in my hangar.

North American B-25 Mitchell (50-Percent Scale)

This mockup came out of a “what if” discussion concerning building a scale, multi-engine homebuilt as inspired by the Bally 1/3-scale B-17. A B-25 was settled on using Vernier or Rotec radials. All I could really afford was a cardboard mock-up so construction began. As usual, a set of giant-scale RC plans were used as a basis for the build. The plan was enlarged to make the bulkheads and they were cut from two thicknesses of double wall corrugated board. Large sheets of single, double, and triple wall corrugated board may be bought from most box manufacturers or from Uline Office Supplies. The material is much cheaper than plywood, can be cut with a knife blade in a saber saw, and is quite strong when painted. Both Gorilla Glue and Titebond III were used to stick the pieces together. All corrugated board was coated with urethane clear after assembly. This seals it against minor water exposure. As with the Me 262 I decided not to build the engine nacelles and main gear to keep the overall size within reason. The nose gear was PVC pipe with an inner tube tire.

The front cockpit was equipped with a full panel of fake instruments made up of a combination of paper copies and a six pack drink coaster set, and scale yoke, rudder pedals, and throttle quadrants. The cockpit ergonomics are very good with more room than my Onex. The rear seat is a little tighter, but adequate and equipped with a yoke and rudder pedals.

Several, much appreciated souls showed up on the Saturday scheduled to hang the three aircraft. Earlier in the week Kristin and her father had finished applying clouds to my blue sky and the scissor lift was threaded into the building. Load-rated beam clamps and steel cables with appropriate end fittings were used to provide a safe installation. The aircraft were hoisted into place with block and tackle gear and permanent cables were attached. Supplemental cables were used to “roll” the aircraft into more realistic looking attitudes.

Conclusions and Applications

Building a full-scale mock-up of a complicated, expensive project can save a lot of time and effort should you move on to the real thing. In the case of homebuilt aircraft, especially reduced scale, non-kit (scratchbuilt) versions, there are many details to be worked out before you start ordering and cutting expensive materials. With a mock-up one can finalize the cockpit layout, investigate ingress and emergency egress, and check for the fit of internal components. The location of large parts, such as a battery or a fuel tank, can be checked. One can sit in the cockpit and decide the location of instruments, switches, throttle controls, and many more items. In fact, you could build a low cost mock-up of most anything; a chair, car, boat, or even your personal rocket ship.

All these questions as well as your personal fit can be determined with a mock-up that can be built for the price of a set of RC plans, some FedEx enlargement services, a few sheets of corrugated board, some wood, and some paint. The most expensive single item for all three aircraft was the plastic sheet for the canopies and B-25 nose greenhouse. However, you don’t even need to glaze the mock-up unless you plan to put it on display. When you’re done with the mock-up your grandkids will have a ball crawling all over it.

Credits

I would like to thank the following for their help with this project: David Ullman, Kristin Taylor, Ty Peterson, Steve Wheat, Don Taylor, Philip Peterson, Dennis Fuhrman, Andy Duncan, Al Cleveland, Vincent Dunn, Henry Bartle, and John Gogol.