By Scott Knowlton, EAA 413379, EAA Canadian Council’s newest member

I have heard it often said that in order to build an airplane you need to have mastered a great number of skills, have a large, well-equipped workshop, and hoards of funds to cover the cost of the project. The everyday working stiff, given this line of logic, should come to the quick conclusion that building their own airplane is well beyond their capabilities and their pocketbook. I would like to challenge this line of thinking with the story of building C-FPET, my little Pietenpol Air Camper. Having completed 10 years of service in the Royal Canadian Air Force and arriving at a small airline as a very junior pilot, my financial resources were mostly spoken for by my young family and fixer-upper home at my airline base of Toronto, Ontario. The appeal of the Pietenpol for me was the simplicity of design for an inexperienced builder, the ease of starting an aircraft project from plans, and the basic materials of wood and steel fittings. Spare cash was scarce and this was also a project that I could enter into at my own pace.

For $200 I purchased a set of plans from Bernard Pietenpol’s son Don and for another $200 I acquired an 18-foot length of 2-inch by 6-inch Sitka Spruce from a local boat building supply house. The wood was rough grained and had a small number of pitch pockets but with some EAA books on wood grading and my trusty table saw I was able to make enough rips from this board to build all of my wing ribs as well as the tail group. My one-car garage was only 8-feet, 10-inches by 18-feet but with a small heater, some good lighting, and a couple of EAA tables it became a very comfortable workspace for years of pleasurable building. Over the next few years my wing ribs multiplied and I fabricated real airplane parts like a rudder and elevators — identifiable pieces that I could proudly show a relative, neighbour, or dinner guest who I invited in to my small shop. During this slow introduction to airplane building, I raised a son, renovated our home, and flew my schedule with my airline. That first large $400 purchase of plans and wood was followed by small pieces of 4130 steel for fittings, a torch, bench sander, and vice. None of these items were particularly costly on their own but I felt the satisfaction that not only was my build progressing but also my shop was becoming more equipped. During this time I received a set of Tony Bingelis aircraft building books and a copy of AC 4313 Acceptable Methods of Construction and Repair (subtle hints for Christmas gifts I suggested to my wife).

For almost a decade, the last week of July was reserved for a guys’ trip where my son and I would load up our Honda CR-V with camping gear and head off on a 13-hour drive to Brodhead, Wisconsin for the annual Pietenpol fly-in. I made many friends at Brodhead and my son befriended some of the young kids accompanying their like-minded parents. Over that idyllic summer weekend I would fill a digital camera disk with photos of brake assemblies, strut attachments, instrument panels, and engine installations. At the same time my son would play with his newfound friends and bum rides in Piets, Hatz biplanes, and Aeronca Champs. The following Monday would see us packing the tent and driving 90 minutes north to Oshkosh to attend AirVenture where my son would happily attend KidVenture while I shopped at the fly-mart for parts or attended a forum on welding, rib stitching, or fabric covering. We reserved every afternoon for the air show and spent most evenings around a bonfire or at the outdoor movies.

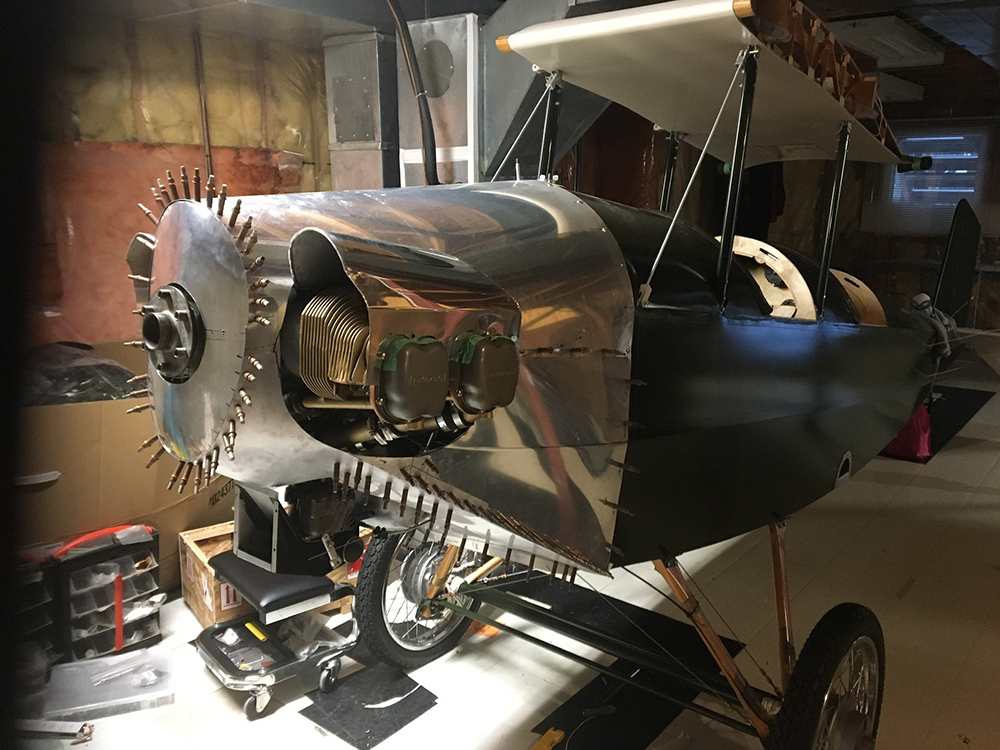

With years passing and my airline seniority and paycheque improving, I was able to purchase a full fuselage kit for $900 and about the same time as my adult son left home I began in earnest to build the major portions of the aircraft. As each was completed, I would move them to the airfield or a friend’s basement for storage, making way for the next item. A half time Continental C-85 engine was discovered for sale in a town not far from me and with the help of a knowledgeable engine buddy we dismantled and inspected it, doing a top overhaul along the way. When it came time to cover the aircraft I ordered all of my fabric and glue from Stewarts System and having attended several of their forums, had no difficulty in the satisfying process of attaching, shrinking, and rib stitching the fabric. It was truly one of the most fulfilling parts of the entire building process.

When it came time to paint the project I once again ordered from Stewarts and built a 2X4 and plastic 10-foot by 20-foot spray booth in my hangar, complete with furnace filters and an exhaust fan. My total budget for the booth was $350. I read the Stewarts manual several times, watched YouTube videos, and practiced painting on butcher paper until I was satisfied with my technique and comfortable with the process. The entire airframe was painted in a week and along with being very pleased with the outcome, I could begin to taste the completion of this airplane and my momentum began to build to a faster pace.

I spent the summer of 2020 doing final rigging, engine install and run-ups, and preparing for my final inspection, which happened in the late fall. My inspector was a fine, knowledgeable gentleman and extremely thorough, which I found to be reassuring. On completion he gave me a small list of items he said he would prefer I rectify before flying. The conditional certificate of airworthiness arrived via email 14 days later. My first flight was Dec. 19, 2020, which was 17 years and 9 days after ordering the plans. My all-in cost for the aircraft is just under $17,000, which represents less that $1,000 per year of construction and my builder’s log shows just over 1,800 hours.

On Dec. 19, 2020, C-FPET left the ground and climbed briskly to 1000 feet in clear, cold 1°C air. The controls were light and harmony perfect. The engine ran strongly and after a high pass, waggling my wings to my building friends, I touched down on our grass runway feeling immensely satisfied with the journey that I had taken to build my Pietenpol. This is only the start of the next chapter and I am looking forward to the summer of 2021 where I hope to make a special journey in PET to Brodhead and Oshkosh if things in our world return a little closer to normal.

A neighbour commented when talking about my first flight in my airplane that he felt I had expended a great amount of time, energy, and funds to just end up with an airplane that I could have simply bought. I reflected on his words and have to disagree on many fronts. The process of building has produced an airplane without question but along with it I have gained many skills, considerable knowledge, a host of useful tools and a tenacity to solving problems that was born in my workshop, on my flight deck over the Canadian prairies, and in my head on nights where I needed distraction from other issues that nagged at me and kept me from sleeping. This airplane was not a consumer of household finances that took food from my family’s table nor did it affect our ability to support our son’s education. Incidentally, I am certain that the years we spent in our lawn chairs at Oshkosh played no small part in his decision to fly for a living and while currently he is furloughed from his airline I expect he’ll return when our pandemic is more under control and may also set time aside in July for Brodhead and Oshkosh one day.

I hope this recounting of the building of C-FPET will spark the interest in other potential builders who have, to this point, convinced themselves that building an airplane will need to wait until they have a bigger shop, bank account, or set of skills. I feel I am a better person for having built my little airplane and am richer in many ways for having done so much of it myself. I still have a lot to learn about building and often am corrected in a process or method by a more experienced builder. I am okay with this because the one thing building has taught me is that you really can learn how to do almost anything.