By Bill Evans, EAA 794228, Chapter 266, Montreal

I found out yesterday the Deuce’s right main brakes were worn to the rivets. I would have bought the pads with the backing plates all ready to go because I am lazy. Neither Laurentide nor Cornwall have maintenance on duty Saturday. Probably means delays while getting them from Spruce. They don’t ship Saturday either. I have designated 2021 for more flying.

I came home to see what I have and brought the plates with me. Turns out I found rivets and two brake pads after an hour’s search. Did not find the tools. It took three tries and an hour on the lathe to make a rivet set and backing button to allow me to rivet them myself. Miraculously the pads I have fit the Deuce. I bought them for the Sonerai.

In the mean time I cleaned up the plates, brushed off the rust, and washed them in alcohol. The last time I riveted pads on, they cracked. So this time I used a dab of metallic Araldite to bond the pads to the plates, hence the alcohol wash. That epoxy dries in two hours so that gave me time to make tools, etc.

By 4:40 I was ready to rivet. It took me an hour to rivet each pad. I was careful because the pads break easily.

I repurposed a clean plastic parts box to organize my brake pad tool kit and parts. I will need more pads if the other side wears out but I’m close to set (pun intended).

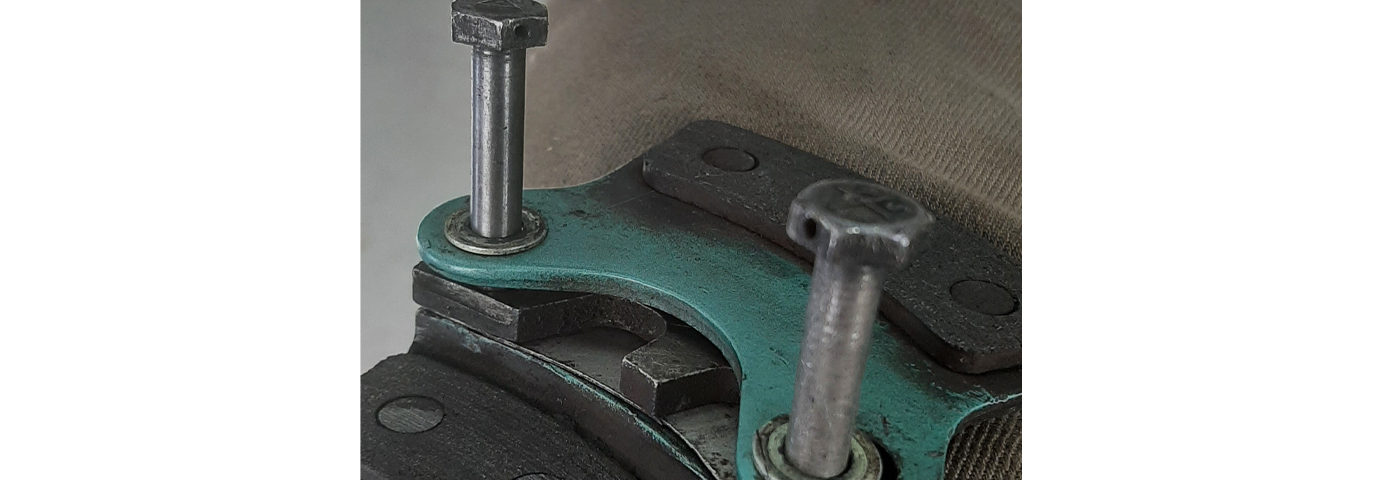

The photo shows Cleveland disk brake pads worn out. When you look at them installed there appears to be brake material left. When you take the wheels off to pack the bearings, the brake pads are worn to the rivets.

I also noticed that when you install the new pads, the final assembly is very close tolerance. You need to satisfy yourself that the wheels will turn without generating heat. That would be part of the test flight or should be. Taxi around a bit to test tailwheel steering and have someone check for heat. If he/she can’t touch the rotors for heat, get some steel shim stock.

The Good Book says all things come to those who wait. Today they came to those who prepare and work.