By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the February 2022 issue of EAA Sport Aviation magazine.

Walt got to the tie-down right after dawn, shivering in the early spring air. He zipped up his parka and began untying the canopy cover. It was one of those glorious spring days on the edge of winter to spring that sent hope through a pilot’s soul. As the cool air tugged at Walt’s jacket, it held a hint of spring warmth. Walt smiled in anticipation.

“Hey!” Bill shouted as he walked up to the airplane. “You ready to go yet?”

“I got a slow start this morning,” Walt replied. “Why is it still so cold?”

“It’s not cold,” Bill said as he spread his arms out. “Feel that sunshine?”

“Give me a hand with the cover. It looks like it has ice crystals on it.”

The two men removed the stiff cover, folded it, and placed it in the truck bed. Walt pulled the canopy open.

“You do the fuel, I’ll do the preflight,” Walt said.

Bill pulled two 5-gallon containers out of the truck and filled the gas tanks.

“Give me a receipt,” Walt said. “I’ll pay you for it.”

“Okay, thanks,” Bill said as he pulled out his wallet to grab the slip.

Walt walked around the airplane and ran through a mental checklist.

“Looks good,” he said. “Let’s go!”

The men hopped in the Zodiac with Walt at the controls. As they taxied over to the runway, Bill said, “I think I’m hearing some kind of noise? Like a thumping?”

“Naw,” Walt said. “That’s the tires from sitting in the cold.”

Taking off to the east, they climbed to 500 feet and started a turn to the north. Then they both heard a loud banging.

“What in the world is that?”

“I don’t know, but we better find out.”

Since they were now on downwind, Walt set up for landing.

“I’m glad there’s no one here this morning,” Walt said as they leveled off over the runway. Just before touchdown they heard the banging again, and then they were on the ground.

“Can’t wait to find out what that noise is,” Walt said. “Hey, thanks for going for the gas. You were going to give me your receipt.”

“Uh-oh,” Bill said.

“What?”

“I can’t believe it. I left my wallet with the receipt in it on the wing before we left!”

“Oh no!”

They came to a stop near the tie-down and both jumped out.

“Yikes,” Walt said, shaking his head as he looked at the nose gear. The aluminum wheel chock had wrapped its rope around the gear with the metal trailing it. The gear and the aluminum were beaten up.

Bill took a look at the wing surfaces, hoping that his wallet might have survived. “No way,” he thought, as he looked at the wing root area. His eyes went to the fairing where he thought he spotted something.

“I don’t believe it,” he said as he walked over to see his wallet. It was half open and jammed into the front corner of the root fairing. The credit cards were neatly arranged in the leather slots. “Well, the receipt is gone, but it looks like everything else stayed in it.”

Walt shook his head. “All right, well, next time let’s use some checklists!”

* *

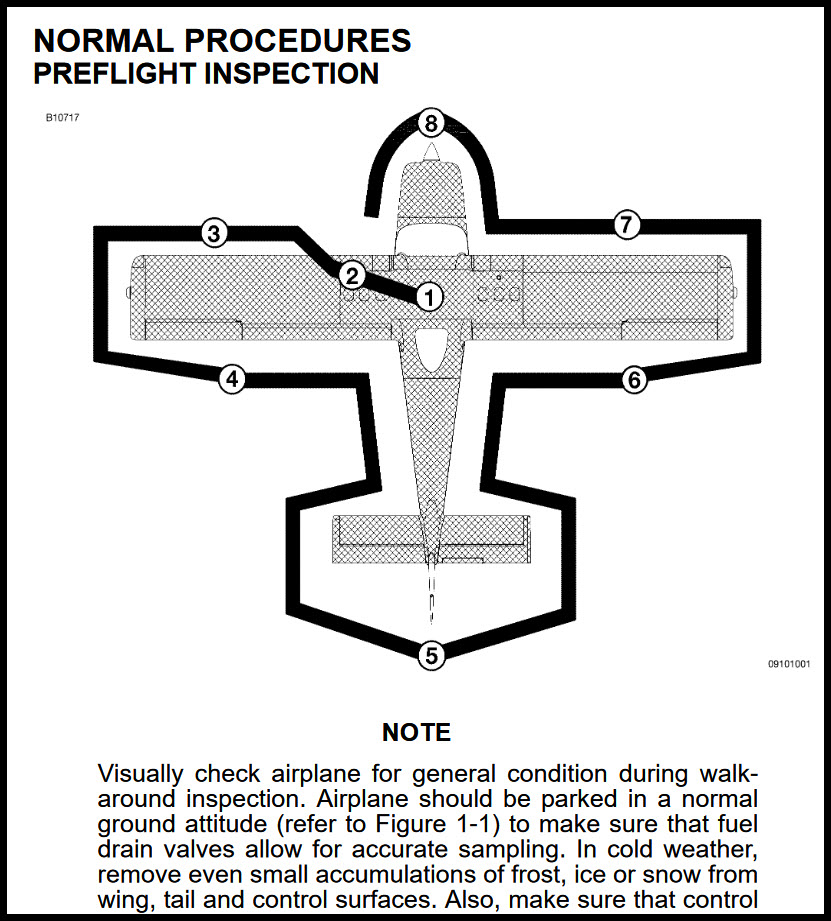

In the last several columns I talked about primary best practices forming the core of success and safety while building your airplane and later conducting your first condition inspection. The third “blueprint” in a natural progression is developing the best preflight practices you can.

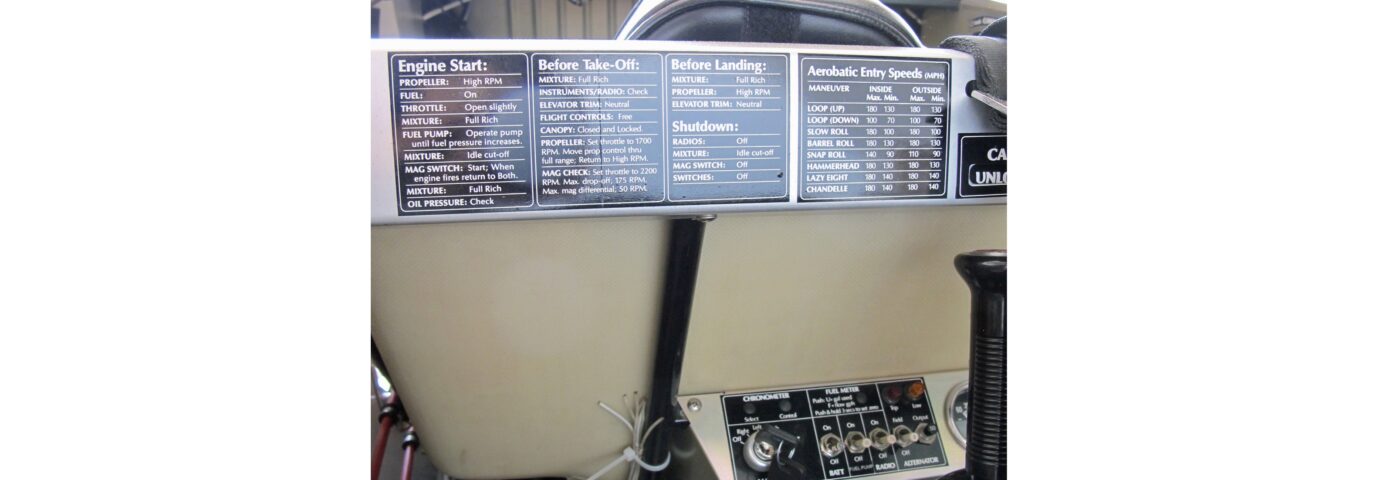

While the certificated machines are straightforward in terms of documented procedures for preflights, experimentals are not. The range of documentation for kits is from none, to some, to a lot. An early design plansbuilt kit may have little in the way of recommended preflight checks. Van’s RVs have some of the best checklists I have seen, and the documentation has gotten much better across the board for almost all kits. But there’s still so much variation that as builders we have to put some work in to get this area right.

Beginning Your Build?

If you’re reading this as you begin your aircraft build, great. You have an opportunity to easily assemble your preflight checklist as you go. In your build log, put a column next to your tasks and label it “Add to preflight checks.” When you see something that should clearly go on your checklist, mark it in your log. Later, when you’re assembling your checklist, you’ll have everything you need. (These notations also work for your condition inspection checklists.)

Finished Your Build?

If you just finished your build, you’re still in a position to develop powerful checklists and procedures. If you haven’t started flight testing yet, this can be a weak spot in the safety net since you want to get in the air. You’ll have a tendency to skip putting your preflight list together. Don’t skip it. This is the time to invest conscientious review work into all of your checklists. Your local A&P mechanic and your EAA technical counselor and flight advisor will be able to help you.

Flying?

If you’re at the end of your build and test flights, but before your first condition inspection, take a look at the checklist you’re using. Is it thorough? Take some time to review it. Are there any other checklists or notes that would enhance what you have? You are in the sweet spot of best practices. The two phases you just went through give you the opportunity to develop reliable procedures.

At this point, most pilots are more excited about flying than refining the checklists. But this is actually the best time to review your lists. The first 300 hours of flight time on your new airplane are important; the first 100 hours are critically important. This is the time to make notes after every flight. This is the time to review your preflight to make sure you’re covering everything.

Don’t forget to:

- Talk to the builders’ group. They will be happy to help you, and you can get a dozen or more sample checklists from enthusiastic builders.

- Study the documentation that came with the kit.

- Draw from the manufacturer.

Overall, get more information than you think you need. You can go back and condense it later.

Tips and Tricks for Preflights

Here are some tips for preflights on experimentals. Those of you reading this with certificated airplanes take heed; these are good practices for you, too. Even though your checklist appears to be a known quantity, there’s probably some room for improvement. Instead of using the standard preflight checklist, why not add extra items to it and print your own list?

The Physical List

Pay attention to the items that you spend more time on, have forgotten before, or worry about. Print and laminate the list. Hate small print? Enlarge the font. Highlight the important stuff. No matter what bells and whistles you come up with, the physical format of your list can make a big difference in how well you pay attention to it. Highlighting, bolding, and fonts make a difference.

Don’t reinvent the wheel. Do an online search for the discontinued Cessna 162 Skycatcher pilot handbook. It contains outstanding checklists that you can adapt as your own.

Post-Flights

Preflights begin with the post-flight of the flight before it. When you exit the aircraft, take note of any anomalies you experienced during the flight and write them down. Once the aircraft is settled in at its tie-down spot or hangar, do a walk-around pretending you are going for another flight and you haven’t seen the airplane in two weeks. See anything? Check it out.

Is a post-flight checklist excessive? Not if your experimental has less than 300 hours on it. You may be surprised at what you find, from a strange drip suddenly showing up to a burnt smell under the cowling. These were both found on one of my airplanes at 30 hours and consisted of an overfilled oil tank and one exhaust section that was a little too close to the fiberglass cowling. These are things you will not necessarily notice on your preflight.

Walk-Arounds

I can’t tell you how many pilots fail to do a final walk-around and end up taking off with something extraneous falling off, or staying attached and wrapping around something. I’ve heard of everything from wheel chocks to gas caps to wallets. Most flights end well, but some do not. The walk-around right before hopping in the plane can do wonders for this problem.

Keep a Notebook in the Airplane

We’ve all experienced situations where we made a mental note to ourselves to write something down “later.” Then we promptly forget what it was. In addition to your phone, where you can record all manner of voice memos, notes, and ideas, a physical notepad is still a good idea.

Get Fancy

Consider integrating photos, even annotated photos using a screenshot program like Snagit, into your pre- and post-flight checklists. You can also record your inspection in your own voice. More sensory cues in any process make it more effective. Our brains simply pay more attention to multiple reinforcing stimuli.

Quirks

Every airplane has its own personality. Make notes about yours. If you were going to turn your airplane over to a new pilot/owner, what quirks would you want to explain? These should also go in your checklist.

Psychology

I’ve been talking this whole time about adding to your preflight checklists. But there’s a point where you have to stop and reevaluate what you have. As humans, we can only pay attention to a certain number of things without zoning out. Add that to a time (preflight) that is super exciting, and you have some complacency. “Oh, I don’t need to check that; it was fine yesterday.”

What I recommend is that you review the final list you came up with and use the techniques above to order and highlight the lists and modify and improve them over time. Periodically review their helpfulness — condition inspection time is good for that.

Now you can hop in and enjoy your flight. Give yourself a pat on the back.

Things We Miss

Here’s a list of things we might overlook on condition inspections.

- Does your aircraft use backup batteries in the avionics stack? Check condition.

- Do all the lights work? Outside and inside?

- Check for firmware and software updates for electronics.

- Have you recalibrated panel electronics?

- Inspect seat belts and especially anchors.

- Have you cushioned all the edges and protrusions in the cockpit?

- Has torque seal been reapplied to hardware you removed or retorqued?

- Are logs up to date, and have you included service bulletin information?

- Are the weight and balance still accurate?

- Is your airworthiness certificate displayed in the cockpit?

- Do you have your weight and balance, operating limitations, and registration in the aircraft?

If you are not doing post-flight checks, consider adding them. Make a separate list for it. It will be shorter than the preflight and will take you only 5-10 minutes. The first time you discover a leak that dries up between flights you will be glad you checked.

A Note on Checklists

Checklists are your single most important tool on your inspections. I cannot emphasize this enough. If the checklist doesn’t feel adequate, spend time improving it or getting another one that is more detailed. While the minimums are specified in “the scope and detail of FAR 43, appendix D,” you should beef up your list using information specific to your aircraft. Some aircraft kits have minimal to no condition inspection recommendations. If this is the case, then other builders should be able to help, as can the manufacturer if they are still in operation. This is one reason why, during the build, you want to document as much as you possibly can for use later.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former DAR. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.