By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the March 2022 issue of EAA Sport Aviation magazine.

“Sandy, come on, we’ve gotta get going.”

“Settle down. We’ll get there on time.”

Kathy shook her head in frustration and waved her hands. “No, we’re going to be late for the jump. The school said 10 a.m. briefing and jump at 11 a.m. It takes 45 minutes to get there.”

“Don’t freak out. Be glad we’re not driving. We definitely would be late,” Sandy said.

“Come on, help me with the preflight.”

“No, mistakes are made when two people do the preflight,” Sandy said. “You do it.”

Kathy sighed and returned to her checklist. I know there’s stuff missing from this list, she thought. I need to take the time to go over this and add to it. “Not now,” she said.

“What?” Sandy asked.

“Nothing, just talking to myself,” Kathy said.

“They say that’s a sign of intelligence,” Sandy said.

“Ha! I hope so,” Kathy said. “Come on, let’s go. I looked at everything yesterday.”

“Okay, okay.”

They hopped in the small composite aircraft, and Kathy ran through her checklist. The engine started quickly. They taxied slowly to the runup area to let the oil temperature come up. On the runup, the engine began to run roughly.

“Am I making this up, or is the engine sounding rough?”

“Rough,” Sandy said.

“Let me switch tanks.”

Kathy reached down and pushed the fuel lever to the other tank. The engine smoothed out.

“Oh shoot. What are we going to do?”

“Drive to our parachuting class,” Sandy said.

“We’ll be late.”

“Would you rather be late for class or stuck in a cornfield halfway there?” Sandy asked.

Kathy cocked her head to the side and then taxied back to the tiedown. “Thank you. I was about to get overexuberant.”

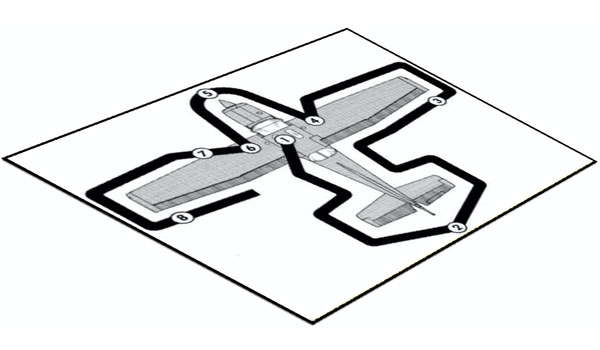

Last month I concluded the “blueprint series” on experimental building, inspections, and preflights. This month, I’ll add to the preflights topic with specific problems to look for as you develop your lists. Although these tips are specifically for homebuilt aircraft, many of them can be incorporated into preflights for certificated aircraft. As you’ve noticed by now, much of this is common sense. Here are the traps I see over and over again when I look at homebuilt aircraft and preflight procedures.

Time pressure. We may feel that we’re allocating enough time for our preflight. But we’re living in an era when there simply isn’t enough time to do everything we want. Add the chronic inability to estimate how long a task will take, and we end up pressured. Taking the time to prepare for a flight is critical. We sometimes make our minds up that all is well and then cut preflights or planning short.

Distractions. Getting off track is easy and very human. We assume that we can jump back in and pick up where we left off, but we rarely do. Integrate the preflight into your flight planning and treat it as a standalone unit. Run into the flight office before or after the preflight, but not in the middle of it. I don’t recommend that you share preflight checklist responsibilities unless communication is good and you understand the capabilities of your companion. It’s too easy to assume the other person looked at everything that you didn’t.

Skipping items or the entire preflight. “This was fine on the flight yesterday; there’s no reason to check it again,” we say. When you say this, stop for a moment and think about it. When you come out of the $100 hamburger joint (which is now $175), take a good look at the airplane before departing. You need to use your judgement on this. While you may not need to go into great detail, do check the basics. Fuel and tires come to mind, with a thorough walk-around.

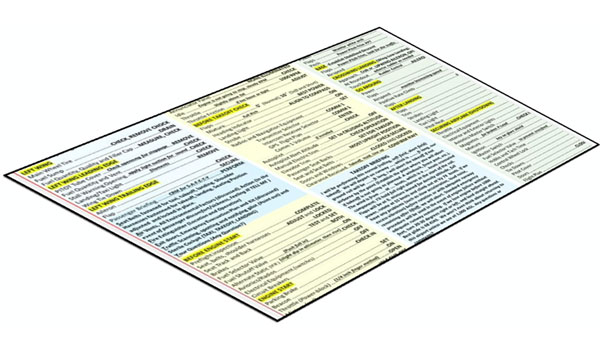

Poorly developed lists. Once again, exuberance wins over and we default to getting in the air over spending time refining our checklists. Excitement is a wonderful feature of flight, but we should recognize it and make time for checklist refinements.

In looking at builders’ prefight checklists, I also see the opposite problem. Instead of not having enough items, they have too many items. When the lists are not organized or prioritized, the pilot tends to skip them or miss things. To correct this, analyze what problems you are routinely seeing on the airplane. You should take copious notes in the first 100 hours of flight. Then refine your preflight to match what things you should pay the most attention to. Over time, you can refine your lists so that they are less time-consuming but deliver the safety levels you need.

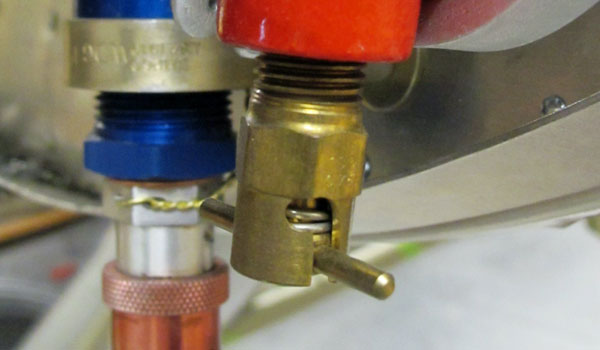

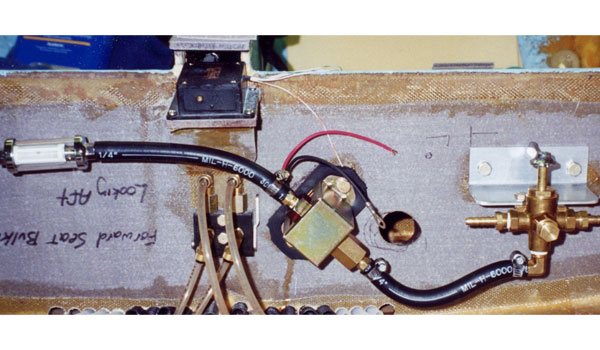

No attention to error-proofing. It’s always better to have systems that will only work the right way. An example is an interlock on a fuel valve that prevents us from turning the fuel off without taking an extra step, and the visual benefit of torque seal on fasteners.

We know that to err is human, but to allow this adage to normalize our procedures takes us down the wrong path. We should explore every possible way of ensuring our flight safety — redundant systems, if you will. Having both good design on a fuel selector and legible and correct labeling makes it more likely that we will not commit an error when selecting tanks.

Our homebuilts are more prone to these types of errors than certificated aircraft simply because they are not all built in the same way. But this same characteristic can make our homebuilts every bit as safe and error-proofed as certificated aircraft coming off an assembly line. To do this, we have to combine the error-proofing at both the build stage and then later at the checklist development stage. Once we think we’ve done everything possible, then our job is to refine the checklists and procedures to give us another layer of safety.

Your attention to error-proofing will be necessary on scratchbuilt aircraft and most kits. You’ll find that some of the kits with hundreds of aircraft flying are extraordinarily well developed, and the designers have thought of nearly everything. In that case, make sure you use their excellent checklists and refine for your specific aircraft.

Error-Prone Items

Fuel systems should get extra attention on preflights. Because no two homebuilts are alike, fuel systems may be built and routed differently, sometimes creating unnecessary problems. The two most common traps are filters and venting.

Builders use all sorts of fuel filters, from tractor paper filters to very fine mesh, glass-encased filters. The paper filters work when new but can swell and clog, creating fuel starvation at the engine. This is an insidious situation where things seem to run fine on the ground and fail when you get into the air, usually during or right after takeoff. The high-temperature glass filters are nice because you can easily see the fuel in them. What you may not see is the fine debris filling them over time. Even if it means removing access covers, check these for clogs and leaks on your preflight. Most important, use the filter type the manufacturer recommends, and in the locations it recommends.

Fuel will not flow without air venting. As the levels drop in tanks, enough air must be able to get in or you’ll create a vacuum and the fuel will slow or stop. It’s a good idea to have more than one vent in case one gets clogged. An important item on your preflight is making sure all vents are clear of both fuel and air.

I mentioned in last month’s column that your preflight begins with post-flight checks. You’ll find things after a flight that will not reveal themselves before a flight. Post-flight checks are also a good practice for pilots flying certificated aircraft. The checklist does not have to be long.

Don’t put your preflight or post-flight checklist away without moving away from the airplane and looking at it carefully from a distance from all sides. You might be surprised.

We know that accidents usually end up being an accumulation of small errors. Don’t allow your preflight to contribute to any of them.

* *

When Kathy and Sandy returned to the field and inspected the airplane later that day, they discovered a clogged fuel filter coming from the left fuel tank.

“I should have checked this more often,” Kathy said. “My tech counselor told me that fiberglass aircraft seem to manufacture little bits and pieces of glass debris even though you’ve done what you think is a thorough tank cleaning, and it can continue for quite a while.”

“Better that we found out on the ground.”

“Yes. And it all worked out — we weren’t late for the jump class. Congratulations! We’ve both now jumped out of a perfectly good airplane.”

“Speaking of perfectly good airplanes, you better add that filter check to your preflight,” said Sandy.

“Thanks for reminding me. Got it.”

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former DAR. She built and flew a Pulsar XP and Kolb Mark III and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.