By David and Andra Meyerson, EAA 1304039

This piece originally ran in the April 2022 issue of EAA Sport Aviation magazine.

Five years back my wife and I decided, having built and flown a terrific racer, a Lancair 320, that it no longer coincided with our ability to be strapped into a very small, very fast aircraft. Looking around for our next airplane, we zeroed in on RVs for their great reputation and aircraft performance that matched what we wanted.

Shortly thereafter we traveled out to the factory in Aurora, Oregon, to see for ourselves just how the components were manufactured and get a detailed look at a mostly completed RV-14A. I was impressed with Van’s manufacturing process and customer service, and shortly thereafter began purchasing the various kits that eventually would become N497RV.

I have the advantage of having worked in and around GA aircraft maintenance for quite some time, so the basics of how to assemble an airplane were not a new experience. What was interesting was honing my riveting skills. There turned out to be quite a difference between installing a skin patch with a half-dozen rivets versus spending days riveting panels together. The tool that I found most useful during the process was a pneumatic rivet squeezer. Once set up it produced excellent results, leaving little use for de-riveting equipment.

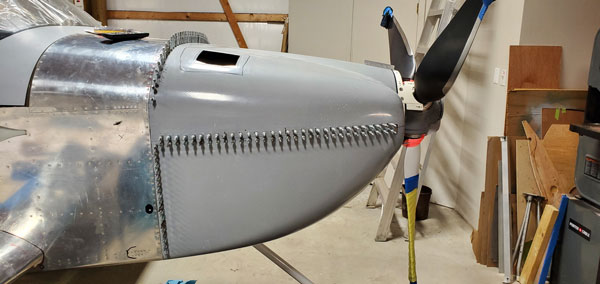

We decided to build this airplane with state of the art avionics — a full Garmin suite — with a coupled autopilot. I worked with SteinAir who designed and built the system. Its customer support did a terrific job when it came to the inevitable questions. The engine is a Lycoming IO-390, plain vanilla version; the prop is a three-bladed Whirl Wind specifically designed to mate to the engine.

We own a hangar, and most of the assembly was accomplished there. Sometimes it was a bit of a trick working around the Lancair that was housed in the same hangar, but it was well worth the effort. No matter how much room one has to build an airplane, it is always at least 1 foot too short and 6 inches too low. Having said that, some of the kit assembly was done at our house, upstairs in our two-story garage. Of course the trick was figuring out how not to build a boat in the basement. After careful consideration, we did manage to get it just about right, only having to disassemble small pieces of the ramp railing leading from the door to the driveway to get the forward section out.

So there we were with a mostly completed airplane, and the coronavirus pandemic struck. There was no better way to spend time than completing our project. My wife and I spent the better part of a year at the hangar working four or five days a week, several hours a day, and finished the airplane. To keep focused on the work is always a challenge. Sometimes it felt as if we were doing nothing but building parts with no obvious progress. Simply putting everything down and walking away for a couple of days reinvigorates. Sometimes putting that part of the assembly process down and moving on to something else and coming back to it a few days later works. There is so much to do assembling an airplane that there is always an opportunity to turn a few pages forward in the instructions, build that up, and come back later to the pile of parts that was flummoxing you. Clearly the best option for staying focused is working alongside someone who has the same goal, similar type skills, and patience. Nothing beats that.

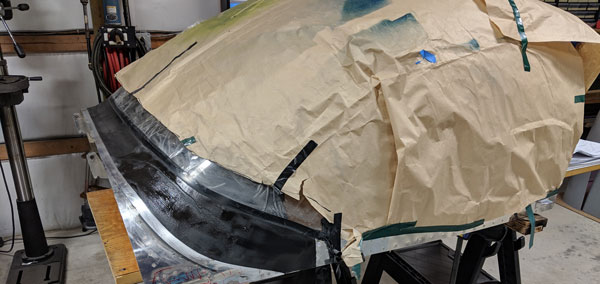

Having built and painted an experimental aircraft before its first flight, I came to the conclusion that it is not the way to proceed. A terrific paint job completes the project and makes it look amazing. What I did not want is a perfect paint job that I had to work around to do small fixes and detail work during and after the 40-hour test flight period. We had that situation with the Lancair, and working like that was truly nerve-wracking. In the end we wound up repainting parts of the cowl because of mods we needed to make and rashes we caused opening and closing it. So we are waiting for about a year or perhaps the first 100 hours before paint is going on our airplane. I don’t know what that design will look like, but we have plenty of time to figure it out.

The art and science of assembling an airplane fascinates me and by extension I suppose many amateur builders. My suggestion to anyone who wants to build an airplane is to find an EAA chapter that is currently assembling one and work along with experienced builders. It will provide you with a good feel for what you are getting into, how many hours it is going to take, and what level of skills and tools are required. There is a long litany of partially built airplanes for sale, just look on Barnstormers.com. The best way to not be one of “those” people is to do your research thoroughly before plunking down money on any kit. If you get bogged down, consider bringing in fresh talent, if only for a short time. There is no lack of helpers out there, some with better skills than others, but all willing to work. Find a part of the project that matches the skills and have at it.

Don’t forget, building the airplane is only one part of the process. Clear proof of what you accomplished is a must. You cannot have too many pictures nor too complete a log. The designated airworthiness representative (DAR) coming to inspect your airplane wants it to pass. Have all of the paperwork associated with the DAR’s visit in perfect order. There are several guides available on how to get it correct the first time.

Have fun!

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own.