By Vic Syracuse, EAA Lifetime 180848

This piece originally ran in Vic’s Checkpoints column in the May 2022 issue of EAA Sport Aviation magazine.

I’ve written many columns, and even a book, on prebuys. The common message I have put forth in each of them is that it is important to have the prebuy done by a person who is knowledgeable on the particular aircraft. A checklist is of paramount importance. If there’s not one available pertinent to the type, then try using FAR 43, Part D as a guideline. It’s important to not wing it. I guarantee things will be missed. I am going to use this month’s column to help drive the point home.

I see about 250-300 different airplanes each year as part of my maintenance, designated airworthiness representative (DAR), and prebuy activities. Most of them are well built and well maintained by owners who have a real passion for aviation. However, there are times when I must remind myself that this is amateur-built and experimental aviation. Sometimes it is not at its finest.

The most recent and shocking example involved an RV-6A that was towed to our shop one evening after landing. I had been asked about doing a prebuy on it, but since it was in California, I declined, as I am not traveling commercially due to COVID-19. It was going to be the buyer’s first airplane. Being new to amateur-built aviation, he managed to find a DAR in California who was willing to do the prebuy inspection. Once that was completed, the aircraft was purchased sight unseen, and the buyer found a local ferry pilot from Falcon Field (KFFC) to bring it back with him from California. Falcon Field is located near Atlanta, so it would be a great cross-country trip to get some time in the aircraft.

Lest you think this column is just self-serving because I do prebuy inspections, you might want to sit down before you read the next sentence. The aircraft was towed to our hangar because the propeller departed the aircraft as it was in the flare for landing. I had left for the day, but my son, Nick, was still there. He remarked that he heard it making awful noises as it came down final, sounds that he had never heard from an airplane. He lost sight of the aircraft behind some trees as it touched down, but another customer saw the propeller depart the aircraft. Luckily, the ferry pilot immediately reduced the throttle and landed uneventfully. (Well, almost. The co-pilot’s left side brake didn’t work. It turns out the brake reservoir was empty.)

The story goes that the pilots noticed vibrations at various rpm on the trip from California, but could get them to go away at 2400 rpm. This particular flight was the first flight after landing at KFFC. The purpose of the training flight was to do some air work, including stalls. The new owner then planned to fly it home to Auburn, Alabama. During the stall series, the vibrations intensified, and the decision was made to head back to the field. That certainly ranks up there as one of the best decisions I’ve ever heard.

I couldn’t wait to get back to the shop in the morning to investigate, all the while thinking about how lucky they had been on the trip home. There’s lots of desolate terrain between California and Atlanta. Not that the outcome really matters where the prop might come off. Surprisingly, the composite prop and spinner showed minor damage, and I was happy that the spinner was still attached, as it meant the bolts should still be there.

My initial thinking was that the prop bolts had not been properly torqued when it was installed. There is no logbook entry for the composite propeller installation. We know there was a metal Sensenich propeller installed at some point. Twenty hours prior to the sale, there is a logbook entry stating that a James Aircraft cowl was installed, along with a metal propeller crush plate “for W&B.”

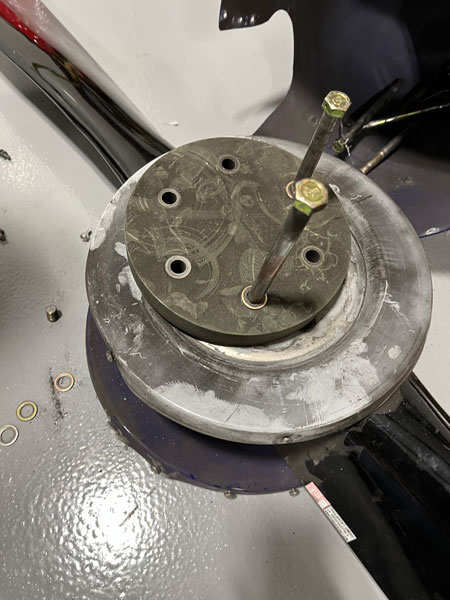

All of the prop bolts were inside the spinner. The safety wire had all been broken, and three of the bolts were sheared, with the remaining three all having been stripped of their threads. The aluminum spacer had severe fretting in multiple places, which is caused by the propeller being loose. The drive lugs on the spacer had “oblonged” the holes in the propeller. Clearly, this propeller had been loose for quite some time.

Careful inspection of the front of the propeller showed evidence of washer indentations into the propeller hub, indicating that the propeller had been installed at one time without a crush plate. Wooden and composite propellers require a crush plate. Keep in mind that a metal propeller had been removed, so there was no crush plate. I could also see that the forward spinner bulkhead was deformed from the bolts and washers, plus it was not an entirely flat bulkhead as is common on the RVs. It had a little ridge on it, which I think came into play to set up the eventual failure.

The installed crush plate for “W&B” was central to the failure. The problem here is that it was a 7-inch diameter crush plate while the propeller needed a 6-inch crush plate. This 7-inch crush plate now sat on that ridge line I mentioned, keeping it slightly above the propeller. Even with proper torque applied to the mounting bolts, there was no way this crush plate was going to fit tight against the propeller hub and properly secure the propeller to the flange. After 30 hours, it all finally let go.

There’s a big lesson here for new owners, whether you built the airplane or not. Yes, one of the attractions to amateur-built aviation is that we get to do our own maintenance and modifications without a lot of oversight. But we must remind ourselves that that freedom also comes with responsibility. Some changes and modifications have the potential to cause severe injury or death, and perhaps it is wise to get some help or advice. Luckily, nobody got hurt here, but it is still going to be expensive. Lycoming has a mandatory engine teardown for propeller separation. The teardown, rebuild, and labor to remove and install will be close to $15,000.

I also have some concern with the bolts that were used. They are F911 bolts, such as the ones that are used in the auto racing circuits. The shorter bolts holding the spacer to the engine flange look to be high-quality F911 bolts. The longer propeller bolts look to be cheap, even though they are stamped quite poorly with the F911 logo, and the plating is of a different color and is flaking off. There is some noise out there that bogus F911 bolts are being made in China. Propeller bolts usually have rolled threads, not cut threads. Rolled threads are up to 35 percent stronger. Look at the picture and judge for yourself.

But the story doesn’t end there. I also had a chance to look a little closer at the whole aircraft. It clearly isn’t a showplane, but not all of them are, and there’s no problem with that. It’s what’s under the covers that counts. In this case, some of the findings were alarming and should not have been missed on the prebuy. One intake tube had such a horrible leak that blue fuel stains were running down the intake tube and onto the valve cover drain-back tube. Other intake gaskets were quite brittle.

The oil had not been changed in more than seven months. An unsecured, cheap rubber Koozie was used between the cowling and the engine intake, which fell off when the cowling was removed. All the engine controls were mounted to engine mount tubes rather than to the engine. No mention was made in the logbooks as to the status of the P-Mag service bulletins.

The fuel pump inlet and outlet fittings were sealed with RTV adhesive. Upon removal from the fuel pump, it was noted that the RTV had migrated into the fuel pump. This has the potential to cause a complete fuel blockage or restriction. The throttle linkage had been lengthened by using a brass turnbuckle, and of course, it was missing a jam nut.

I hate to steal an old advertising line, “but wait, there’s more.” The new owner mentioned that the heater duct was only on the right side, and he had been cold in the pilot’s seat on the way home. I pointed out that the heater outlet was on the firewall on the co-pilot’s side, and he mentioned that hot air was coming from out of the vent on the co-pilot’s side, but nothing was coming out of the pilot’s side. I mentioned it was an outside air vent and should have been cold air, but he was certain it was warm air. So, I traced the duct from the vent on the co-pilot’s side and couldn’t believe what I found. It was connected to a flipper valve on the firewall. When activated, it was allowing engine compartment warm air into the cabin. That’s a great source for carbon monoxide poisoning.

While I was tracing the right-side duct, I looked at the pilot’s side vent and couldn’t believe it either — there was nothing connected to it at all. It was fake from day one as there were no NACA ducts on the aircraft, or any other source of fresh air. I can only imagine how hot and uncomfortable that cabin must have been on warm days.

We haven’t finished looking at everything yet. The engine teardown will take six to eight weeks, so we still have some time. I’m hoping we have discovered the worst of it. I feel for the new owner. Flying your newly purchased airplane home, only to have it immediately grounded and incur some unexpected expenses can put a real damper on the fun factor.

By the way, I saw the original prebuy report. None of what is in this column was caught or mentioned.

Vic Syracuse, EAA Lifetime 180848 and chair of EAA’s Homebuilt Aircraft Council, is a commercial pilot, A&P/IA, DAR, and EAA flight advisor and technical counselor. He has built 11 aircraft and has logged more 9,500 hours in 72 different types. Vic also founded Base Leg Aviation and volunteers as a Young Eagles pilot and an Angel Flight pilot.