Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the September 2022 issue of EAA Sport Aviation magazine.

The joy of building or restoring your own aircraft lies in the challenge of the assembly in addition to the dream of flying it. It is the best of both worlds. Depending on your choice of kit or restoration, the project will have numerous complex systems. These can be a welcome challenge or a point of worry.

Once the parts and pieces are in your garage or hangar, you may start rethinking it. How you decide to handle wiring, avionics, engine installation, upholstery, and paint will bear directly on how successful you are and when the project gets in the air.

When folks were building airplanes in their garages in the ’80s and ’90s, many of the kits arrived with the bare basics. Fuselage or frame, wing parts, canopy parts, control surfaces, mounts, and some hardware. Absent were wiring harnesses, avionics, finish materials, and engines. Now, you can choose kits that contain everything you need to fly, sans avionics and engine, which are usually builder choices. Quick-build kits abound, and instructions have gotten more detailed.

However, if you choose to restore a homebuilt, build a kit from plans, or pick a kit without a ready-to-go electrical system, this leaves the installation and avionics up to you. How do you decide whether to put the electrical system in your airplane yourself? What pitfalls lurk? Should you fabricate your own panel and wire the avionics? There are lots of tasks that we’re permitted to outsource if we’re uncomfortable doing them ourselves. Smart decisions about this will drive the quality and speed of your project assembly.

When I built my first aircraft in the ’90s, the electrical system was straightforward. I decided to work with the schematic that was provided in the kit along with several textbooks. At the time Bob Nuckolls’ book, The AeroElectric Connection, was a standby. Now we have many more helpful books on wiring (Marc Ausman’s Aircraft Wiring Guide comes to mind) and plenty of outstanding videos from EAA’s Dick Kohler.

We need the extra help now because of the extra levels of complexity: Modern homebuilts can have sophisticated glass cockpit displays, extra antennas, ADS-B receivers, backup alternators and batteries, autopilots and electric trim, sound systems, and an assortment of warning systems. More wires!

If you decide to wire your airplane, here are the things to think about and the common troubles to avoid.

Psychology

The better you understand yourself, the more you’ll accomplish. Self-knowledge that comes from being honest about your shortcomings will pay off later. Electrical wiring in particular requires attention to detail, closely following advice and recommendations, and checking and rechecking work. Like filling pinholes, wiring is not a fast job, and it requires buckets of patience. In making the decision, realize that you may need some education.

Training and Education

Training is hands-on practice. Education is finding out what everything does and why. If we have both theory and how-to, then we’ll understand how the components fit together.

Unless you’re an electronics technician or an A&P mechanic, I recommend you attend one of the EAA SportAir Workshops and read a few of the current books on wiring.

Materials and Tools

My motto is “Any excuse to buy a tool is a good excuse.” Building an airplane is one of the best reasons around for purchasing just about anything. But seriously, wiring is one area where you do not want to fall back on your cache of automotive wire and terminal sets.

There are two reasons for this. The first is material. Automotive wire is made with PVC or vinyl insulation, which makes it attractive to mice and toxic when overheated. What do the instructions call for? What does the manufacturer say? In many cases, you can use Teflon wire as well as Tefzel.

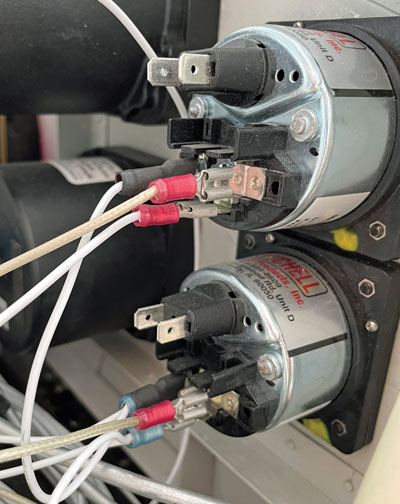

The second reason is quality and function. Automotive terminals are made differently and are not intended for high vibration aircraft environments. Aircraft terminals have better insulation and a larger interior sleeve.

If you’re going to use aircraft grade materials, then you need the correct tools for the job. In your training or reading, make a list of what you need. This will include the correct crimpers for the various terminal connections you’ll be making. Get an automatic wire stripper. Manually stripping wire is an opportunity for nicks and breakage. In the grand scheme of things (all things aircraft), these are not expensive. And here’s another good reason to belong to a local EAA chapter — tool availability.

Shortcuts

If you decide to do the general wiring, you can still outsource some of the more complex pieces of it, such as the panel and avionics harness. Your avionics supplier may cut your panel at little to no charge when you purchase the instruments and electronics.

Common Trouble Areas

Connections. When we find electrical components not working, it is rarely the device that is causing the problem. Modern electronics are reliable. The weak link is the connector. This is the reason you want to use the highest quality you can and understand how to correctly strip wire and assemble and crimp fittings.

When I visited builder projects as an EAA technical counselor, I had a habit of pulling on wiring to see if the attachments were done correctly. You can imagine that this was very annoying to the builder, especially when a poorly crimped wire came off in my hand. Better now than later.

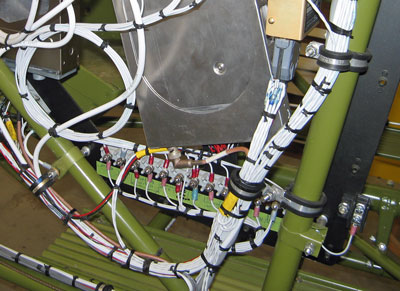

Securing bundles. As you evaluate where wires are going, determine whether you need protection for them, such as a spiral wrap, and use the traditional method of lace tying the wires. Where necessary, use Adel clamps to secure the bundle inside the aircraft, noting where it might abrade. Zip ties are okay, but take the time to cut them off squarely so that they don’t hang up on things or on you.

When troubleshooting electrical issues, I’ve found plenty of instances where wire abrasion caused the failures. When it happens inside a cavity, it is all the harder to find and repair.

Pathways. Where are you running the wiring? Follow the directions if you have them. If you have to improvise, look at the areas where you want them to go. Is there anything that can cause wear and tear?

Labeling. While time-consuming, it’s a good idea to label wires while you are assembling things. It’s easy to get interrupted, come back, and assume you were working with a certain circuit and then have it be wrong. Once the harnesses reach their destinations, it’s helpful to label circuits and, of course, the switches. A circuit tester is handy.

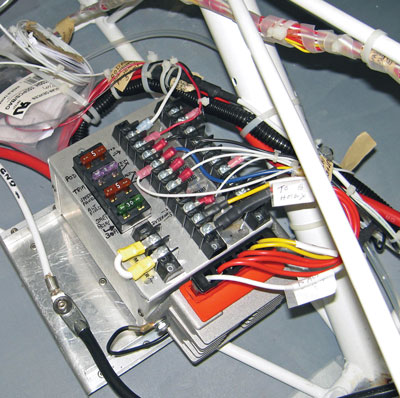

Circuit breakers and fuses. Don’t overdo it. I’ve seen projects with so many fuses in a circuit we didn’t know how to find the one that blew. In one installation, duplicate fuses were under the passenger seat behind a panel. Try to get to that box in an emergency. The important circuits should be on your instrument panel; I favor the push breaker or the switch type breaker.

Grounding. No matter how many items you have wired in your truck by connecting the ground wire to the chassis, you do not want to do this in your airplane. Instead of calling it a ground wire, call it a return wire. Having a point where all “return lines” assemble, or a ground bus, is as important as the power bus. Avoiding ground loops is one of the keys to clean audio. More work and more wire? Yes. But it will be done right.

Third-Party Solutions

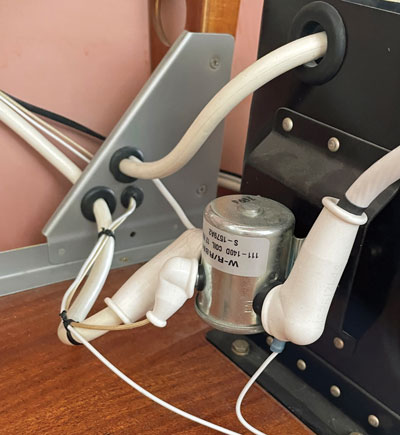

For my second airplane, I purchased an all-in-one box. Billed as a complete electrical system for aircraft with a starter, it contained a regulator, starter solenoid, terminal strips, and a fuse panel. I got wrapped around the axle trying to figure out what components I needed to install ahead of, and after, this magic box.

This was not the fault of the box but my own because I found it confusing, and I could no longer follow the schematic that I was used to. In other words, it was too simple. If you decide to use these shortcuts, rely on the accessory box circuit diagram and instructions so you don’t add something that is already in the box (like I wanted to do).

If you’ve decided to do the wiring, and halfway through you feel overwhelmed, there is no shame in stopping and getting a pro to either help you or finish the job for you. In the projects I have visited as an EAA technical counselor, it’s always been better to back out than charge ahead when it’s too complex. I’ve seen a level of frustration in builders that ran so high that it destroyed their confidence and risked the completion of their project.

When you’ve done the self-searching up front and understand the project component parts, you’ll be able to decide which systems you want to tackle. This lowers the uncertainties in your project and brings back that magical combination of joy and accomplishment that building, restoring, and flying your airplane brings.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former designated airworthiness representative. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.