By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the December 2022 issue of EAA Sport Aviation magazine.

“Keep up your bright swords, for the dew will rust them.” — William Shakespeare, Othello, 1603

“Okay, I’m ready,” Tom said. “Give me a hand getting these wings back on the PA-12?”

Brent and Sally grasped the inboard corners while Tom maneuvered the outboard end to help them attach the bolts at the fuselage and then the lift struts. Tom marveled at the beauty of the now freshly covered and painted, cream-colored wing with shiny red trim. After the attachments were made, Tom breathed a sigh of relief and stood back from the supports to observe the Super Cruiser.

As they prepared to install the second wing, Tom heard a muffled snap and saw fabric wrinkle in the doorpost area.

“What was that?” Sally asked.

“I don’t know, but I don’t like it,” Tom said.

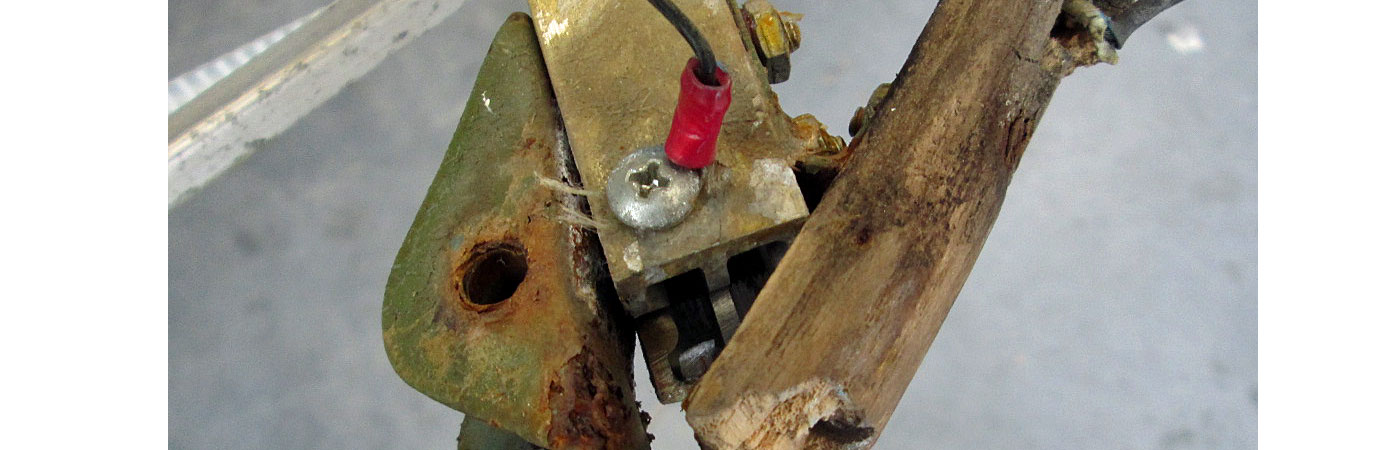

Thirty minutes later, after cutting out a section of fabric, Tom was staring at a rusted-through crack at the top of the door-frame post. More than a quarter of the tube had rusted through, creating a void.

“How could I have missed that?”

“You only covered the wings,” Brent said. “With an airplane this old, 1947, you should have taken it down to the frame, done an inspection, and checked service bulletins.”

“Now you tell me,” Tom said.

Corrosion

The second law of thermodynamics states that “as one goes forward in time, the net entropy (degree of disorder) of any isolated or closed system will always increase (or at least stay the same).”

The second law of thermodynamics states that “as one goes forward in time, the net entropy (degree of disorder) of any isolated or closed system will always increase (or at least stay the same).”

We’ve all seen corrosion up close and personally in machinery and vehicles. It is the law of entropy in action. Planet Earth continues to present us with the challenges of chemical interactions in a world filled with metal.

FAA Advisory Circular 43-4B contains 126 pages of information on aircraft and corrosion. It begins, “This advisory circular (AC) is a summary of the current available data regarding identification and treatment of corrosive attack on aircraft structures and engine materials. Corrosion inspection frequency, corrosion identification, and especially corrosion treatment continues to be the responsibility of the operator.”

Even though this AC is aimed at commercial operators, it can be an excellent go-to publication for small-aircraft pilots and owners. For detailed questions in specific technical areas for your airplane, I recommend being familiar with 43-4B on corrosion, and also AC 43-13-1B, the A&P mechanic’s standby reference on repairs.

Rather than try to cover corrosion A-Z here, I’m going to hit the top things to think about in a variety of circumstances that will help you stave off this insidious chemical reaction on and in your aircraft.

Here’s when to pay attention and what you can do.

Storage

When you stop flying for a while, the corrosion gremlins arrive in force, uninvited and unplanned. Your preflight checklist should have a section for resuming operations after what you would consider to be a time long enough to warrant extra inspections. This will be different for every aircraft and is dependent on age and how well the aircraft has been maintained. Find out from the manufacturer what the recommended time frames are for extra inspections, and what to look for.

Resuming flight operations short-term is one thing, and pulling an airplane out of storage is another. Don’t allow a short-term interruption to turn into long-term storage; too much deterioration can occur. Long-term storage is a lot of work and requires a formal plan and checklist. But it’s worth all of it for the longevity it provides. See the November 2018 Airworthy column, “Haven’t Flown in a While?” for more insights.

Operating Environment

In what part of the country do you fly? There’s a reason why aircraft are stored in Tucson, Arizona. The environment is dry, with low humidity. As you move toward the coasts, the environment progressively becomes more conducive to corrosion. When I was an aircraft owner in Florida, I was fortunate enough to keep the airplane inside a hangar. Combine this with inspections and regular cleaning and the risks go down and aircraft life and safety go up.

In what part of the country do you fly? There’s a reason why aircraft are stored in Tucson, Arizona. The environment is dry, with low humidity. As you move toward the coasts, the environment progressively becomes more conducive to corrosion. When I was an aircraft owner in Florida, I was fortunate enough to keep the airplane inside a hangar. Combine this with inspections and regular cleaning and the risks go down and aircraft life and safety go up.

Metal aircraft tied down outside suffer the worst. Without some protection and attention, these aircraft deteriorate fast. The few abandoned airplanes I observed on that small field in Florida took less than a year to become rust covered. Seized hardware, peeling paint, cloudy windows, and flat tires presented a sorry sight.

If you have to keep your airplane on a tie-down, make sure door and window seals are in good condition. Keep the cabin dry, and get a cover that is designed for the airplane and fits tightly. This reduces the chance of funneling grit into the corners and chafing from straps on the paint.

There is some controversy on covers being used in humid environments. Some owners prefer to use sun shields inside the cabin instead. You may want to ask other operators on your field for a recommendation. Keep the airplane as clean as you practically can. Otherwise, contaminants will settle on it and begin chemical reactions.

Component Quality

Atmosphere plus electricity plus metal plus idleness drive corrosion in switches and battery terminals. This is why you want to invest in aircraft quality components and switches. When you replace a component or switch on your certified aircraft, don’t skirt the rules by being cheap. Circulating electricity keeps you in the air along with fuel. I’ve seen enough failures due to corrosion to not think twice about spending more money on a switch.

The same goes for your experimental aircraft. I’ve seen too many builders try to save money with low-quality switches, connectors, and terminal blocks. They regret it later when they’re troubleshooting intermittent issues and outright disconnects. Indeed, we all cringe when we hear “aircraft” before anything we’re buying — tires, bearings, paint — when we know the quality can be as good, or even sometimes better on nonaircraft items, but why take the chance?

Maintenance and Inspections

Looking for damage and corrosion should be on your inspection checklists, both preflight and post-flight, and a big part of your condition or annual inspection. Follow the recommendations from your aircraft manufacturer. In particular, check the propeller blades, constant-speed propeller hubs, cylinder fins, blisters or bubbles in paint, trailing edges of control surfaces, fuel tanks and components, hinges, batteries, and any exposed switches.

You should also be checking service letters, bulletins, and airworthiness directives issued from the manufacturer. If the airplane is new to you, ask an A&P/IA mechanic to help you on inspection technique. If someone else does your annual or condition inspection, make sure they check for these items and that the information in the logs is complete and thorough.

Leaks

Some things accelerate corrosion. They include leakage of a variety of fluids and substances. Batteries don’t mix well with time, causing acid leaks. Sitting water in any location will cause deterioration, as will fuel, coolant, and any other set of diverse chemicals coming together inadvertently.

Restorations

The situation in the story beginning this column is an easy one to get into. Once you begin a repair, it can spiral out of control to the point where you want to give up. I call this “going down the rabbit hole,” where you discover side tunnels and then cannot return without a lot of work and experiments. (Side tunnels = money and time.)

Think twice before beginning what you think is a “minor repair” on an older aircraft, even if it’s been well maintained. If you do your upfront research and decide to go ahead, you’ll be able to proceed knowing what’s really involved. See the October 2021 Airworthy column, “The One Big Thing,” for more.

Painting

The same rules and traps apply to painting anything, not just aircraft: preparation, materials, and information. We have a tendency to shortcut the preparation because we’re excited about the new paint.

If we shortcut the preparation and/or don’t follow the instructions, the paint won’t fully protect the aircraft, and corrosion can form under the paint layers. When you see peeling or bubbles under metal skins, you will have a sinking feeling knowing that could have been prevented if you had followed the longer process.

I don’t need to remind you that paint is one of the most important barriers between your airplane and the environment. A thorough paint job will dramatically lengthen the life of an aircraft.

Buying and Selling

There are two things to consider when buying or selling an aircraft. The first is the investment that you make in maintenance and upkeep that will drive resale value (and safety). The second is having your next purchase thoroughly inspected before you buy.

Many purchasers of experimental aircraft skip the prebuy because they don’t think they can find someone to do the inspection. This not true; you have more reasons to get a prebuy on a homebuilt that any other category. This is not because you suspect poor workmanship (although the prebuy will identify that), but because homebuilts vary widely in their assembly quality and their equipment and accessories. A prebuy will also alert you to any serious oddities. See the sidebar.

Armed with forethought and information, you will be able to make smart choices to protect your aircraft against the ravages of corrosion and take action when you need to without emptying your wallet.

NOTE: Corrosion inhibitors (like ACF-50 or Corrosion-X) are available from many reputable companies. The best ones do an excellent job of protecting interior cavities and surfaces. Because so many companies have entered this market, I won’t recommend a specific product. Check with your aircraft manufacturer and identify what works best for your specific airplane.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former designated airworthiness representative. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Contact her at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.