* * *

While pilots do not have to be mechanics, you’ll recall from your pilot training days that instructors advise you to understand operation basics so you can head off developing problems and troubleshoot issues that come up. You don’t need to know how to overhaul an engine, but understanding how the engine systems work will stand you in good stead. Especially when your airplane won’t start.

Operating an aircraft that starts every time begins with the right maintenance. Rather than talk about troubleshooting in the moment, let’s talk about not having the problem in the first place.

What do you need for a start? Simply put, you need compression, air, fuel, and a spark. Each requirement has its own system of delivery, and it has to be a coordinated effort.

There are lots of reasons an aircraft engine will not start. The good news is that many of the reasons can be obscure and unusual. If we concentrate on the most common events, we can avoid the ones that are most likely to bite. Here are the top five based on what I’ve seen.

Ignition

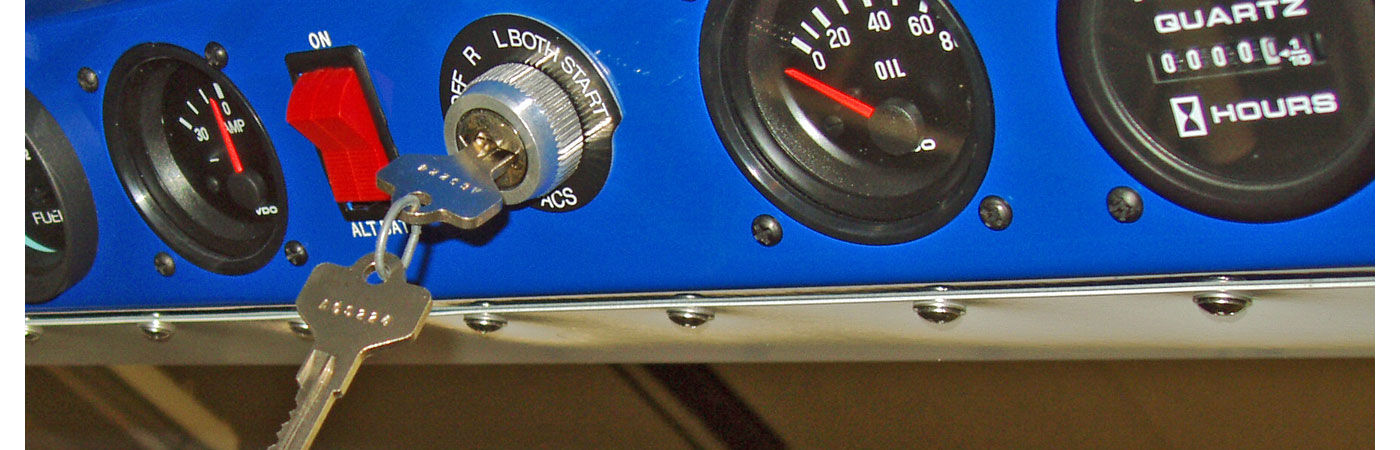

A strong spark delivered at the right time is required for reliable starts. This system begins with a healthy battery and starter (unless you employ a human starter, as in hand propping) with some timing devices (electronic ignition or magnetos, or a mix of both).

Failures I see most often are the battery, solenoid, and starter, and trailing those by a wide margin are an assortment of ailments with magnetos and fouled spark plugs.

Because batteries, solenoids, starters, and mags can all fail suddenly, the key is to inspect and service them following recommended time intervals.

How to Lower the Chance of Battery Failure

Use the battery type recommended by the manufacturer.

Use the battery type recommended by the manufacturer.

Know the approximate lifespan for the battery, and consider replacing it at 90 percent of lifespan. Can it go longer? Of course. But we’re trying to avoid surprises.

Only use a smart charger designed for aviation batteries. Smart is the important part. Charger technology has come a long way, just as battery chemistries have; it’s worth it to spend a little more to obtain the maximum life for your battery.

How to Lower the Chance of Magneto Failure

Actually preventing a failure is ambitious. With what we know about magneto failures, it’s a reach. But magnetos are simple and reliable if they are inspected and serviced regularly.

Some readers may recall strange items like distributors, points, springs, and condensers in the cars they drove “way back.” We just inspected, replaced, and adjusted items as needed. Inspect mags every 100 hours, and plan on parts replacement/overhaul at 500 hours.

Electronic ignitions are remarkably reliable. They don’t belong in this section on common failures except to say if you have an electronic system, be glad. If you don’t have it, consider ditching one mag and installing one electronic side for added reliability and performance.

Fuel

Once you’ve got a strong, timed spark under compression, you need fuel to ignite in that space. This can be harder than you think.

Once you’ve got a strong, timed spark under compression, you need fuel to ignite in that space. This can be harder than you think.

Recalling the story we began with, if you’re flying an airplane with a traditional carburetor, it’s helpful to understand what happens in the system as you go through your checklist. The top trouble with fuel is not following the procedure for start, followed by not knowing the procedure to clear the engine of excess fuel. Find out and know the procedure by heart for the airplane you’re flying, especially what to do if you over-prime (flood) an engine.

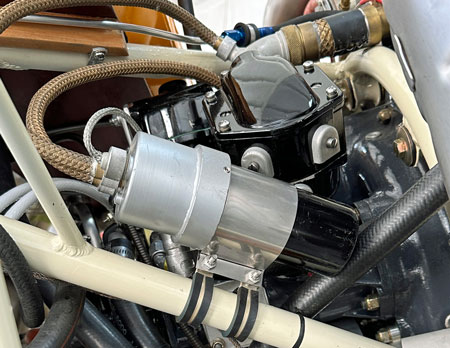

Fuel-injected engines offer an improvement in reliability and performance but also have specific instructions for pressurizing fuel and sequencing the start. Follow the checklist in your pilot’s operating handbook (POH) to the letter for starting. Some fuel boost pumps have several settings — know which one to use and when.

Fuel-injected engines can experience vapor lock on a hot restart. Since the fuel distributor and injector lines are typically on top of the engine, and heat rises, guess what you end up with when you land? A gas instead of a liquid. Follow the directions for your specific system to get the fuel back to a state where it can reach the nozzles.

For two-stroke engines, fuel mix or fuel contamination is a top cause for not starting. My advice is don’t use auto fuel with ethanol. Ethanol speeds up evaporation. Auto fuel will age over time in a way that aviation fuel won’t. Ethanol accelerates the transformation to sludge and varnish. That said, two-stroke reliability is high when you follow the manufacturer’s advice.

Maintenance

Starting problems can appear when preflight inspection items are overlooked, items are not caught on annual or condition inspections, or trends are not caught on engine information systems. Stay tuned in to the data that help you diagnose developing problems.

Mag checks can give you clues to the health of the ignition system. Since you have two completely separate ignition systems, which are also separate from the battery and alternator/generator, the mag check can tell you in a comparative way how each side is performing. If, for example, you suddenly have a large rpm drop accompanied by a rough running engine, it’s a back-to-the-hangar moment where you will check for plug fouling, ignition wiring and timing, and magneto defects. Be familiar with the advice from the manufacturer and don’t skip any required maintenance.

Storage Procedures

If an airplane is not put into storage properly, or not brought out of storage using a specific checklist, hard starting is common. Issues include intake and exhaust blockages, old or contaminated fuel that was not drained completely, and wiring that was damaged by small creatures.

Technique/Checklist

Not following specific starting procedures accounts for at least a quarter of the starting issues we see. I try to be as tactful as I can.

“This is on your checklist?” I ask.

“Ah, this is what I learned when I got the airplane.”

“Let me show you a technique that might work better,” I say, pulling out the POH.

* * *

The principles above may apply, but every type of aircraft is going to be a little different. When in doubt, refer to the POH.

Homebuilts are unique in that they are unique. There will rarely be two airplanes built from a kit that act exactly the same. The exception is a high-production kit manufacturer like Van’s Aircraft. In that case, the uniqueness goes down and predictability goes up. You should assemble a manual with checklists for your kit if the manufacturer has not provided one.

Ultralights also have their share of starting troubles. These are usually related to fuel contamination or electrical issues. In addition to the checklist, be vigilant about using only fresh fuel, monitoring how long it’s been in the tank(s), and giving attention to the filters and oil injection system if it is a two-stroke engine.

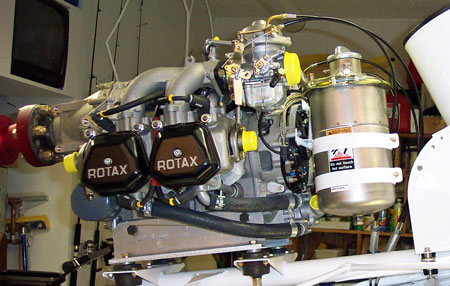

In addition to differences in aircraft, there are large differences in engines themselves. An example is Rotax versus Continental and Lycoming. Rotax places altitude-compensating Bing carbs on top of the engine, and uses ignition “boxes” (electronics) to power the fuel-injection timing. Once again, your mastery of the specific checklist plus understanding the engine configuration is critical in getting the engine to start, and start every time. In my flying with Rotax engines, I told people I was spoiled because all I did was pull out the choke and turn the key.

Get in the habit of hearing, sensing, and feeling what a normal start is for the airplane you fly. If something is amiss, you will know it. One example is the buzzing or clicking sound that goes with a magneto system. You may not understand what is happening or solve it on the spot, but you’ll know something isn’t right. Time to recheck everything and get some additional ears and eyes.

Get in the habit of hearing, sensing, and feeling what a normal start is for the airplane you fly. If something is amiss, you will know it. One example is the buzzing or clicking sound that goes with a magneto system. You may not understand what is happening or solve it on the spot, but you’ll know something isn’t right. Time to recheck everything and get some additional ears and eyes.

Finally, an observation on psychology. One of the many things we love about getting in the air is the anticipation leading up to flight. In the moment of this delight, we often make decisions that can be rationalizations for why everything is okay and we don’t have to “check the list one more time.” No matter how difficult it is to change gears mentally, do get in the habit of getting very serious about all the things you should think about and look at in the procedures. If you have doubts, stop and recheck.

Then get in the air with all that pent-up happiness.

For more engine starting troubleshooting and advice, see “Starting Woes,” Checkpoints by Vic Syracuse, in the September 2021 issue.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P, EAA technical counselor and flight advisor, and former designated airworthiness representative. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.