By Phil Cook, EAA 1006829

This piece originally ran in the January 2023 issue of EAA Sport Aviation magazine.

It all started in early 2014 as I was looking for an airplane to build that would fit my mission — to fly from my house on a paved airpark to my cottage in northern Michigan with a 1,000-foot grass strip (in a tunnel of trees). I’d never built an airplane before so I was looking for a complete kit for an all-metal, tricycle gear, relatively simple-to-build aircraft. I learned that a Zenith 750 Cruzer was going to be the One Week Wonder build at EAA AirVenture Oshkosh 2014, and I rallied hard to get on the tent crew so I could get experience building that airplane. I worked multiple shifts building that One Week Wonder. It was a great experience and solidified my decision to build one for myself.

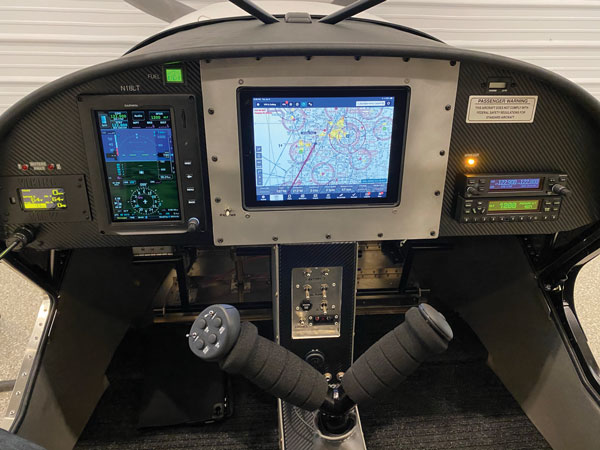

At AirVenture 2015 I formally purchased the complete kit and took delivery at my new airpark house in December of that year. I built it over the next three and a half years pretty much according to the plans with the exception of installing the Viking ‘steel bungee.’ I chose the Viking 130 (Honda) engine and firewall forward kit with its 2.5-gallon header tank system. Being a heavy ForeFlight user I wanted tight integration between ForeFlight and the electronic flight instrument system (EFIS) so it came down to either Dynon or Garmin. I selected the Garmin G3X Touch with a GTR 200 comm. A friend gave me his never-used GTX 327 transponder so all I had to add was a GDL 82 ADS-B transmitter and a GDL 50R ADS-B receiver.

I installed a panel mount from Guardian Avionics for my iPad with stereo integration through the radio’s built-in intercom. ADS-B In and EFIS flight-plan integration with the iPad is via Bluetooth and has been flawless. Powering it all is a Vertical Power VP-X Pro system that provides touch-screen integration via the G3X Touch, eliminates most physical breakers, eliminates the need for some switches, and provides backup controls in case of physical switch failures. Viking View provides the engine information system (EIS) functionality, and an MGL FF-4 unit rounds out everything to give fuel-flow and totalizer functions. An AE AG-6 provides fuel level indications in all three tanks (mains and header tank) and has lighted warning and danger levels (if the header tank is anything less than full, then there’s a problem).

When it came to finishing the airplane I settled on doing a vinyl wrap as I dislike the mess of spray painting. Originally I wanted to do a steam-punk pirate ship theme, but the graphics just ended up being too onerous and complex. I searched around for alternatives, but then it hit me that the most appropriate would be a U.S. Air Force Thunderbirds theme, for many reasons. First, I’m an Air Force veteran of eight years. Also, the Thunderbirds performed at the first air show I attended as a child. (I had a signed poster of the pilots hanging in my bedroom for years after that.) Additionally, the Thunderbirds performed at AirVenture 2014 during the One Week Wonder build, and I caught a great picture of the Thunderbirds taking off directly behind the One Week Wonder as it sat on the flightline. Lastly, when builders (including myself) would get too hung up on minute details and measurements during the build, the mantra from the experienced builders and Zenith was “You’re not building an F-16.” I was a little too detail oriented on my build, so I wanted to reflect that by modeling it after the most famous F-16s!

Even my tail number (N18LT) has significance — my first grandchild was born November 18, and his name is Landon Thomas so N18LT was it! My airworthiness certificate was received September 1, 2020, and first flight was September 13. The airplane performed flawlessly. I used the EAA Flight Test Manual program, and there were no surprises other than how well it performed. My 40 hours were flown off in November 2020, and I’ve been flying it steadily ever since. I’ve been very impressed with its docile handling and full controllability even through what would normally be considered a stall (it doesn’t really stall, it just mushes). The Viking 130 engine is even more impressive, giving the aircraft STOL takeoffs and nose-bleed climb rates. I’ve flown it into my cottage airstrip, and even though it’s a tight, short strip, the airplane made it relatively easy. I’m looking forward to many more years of flying this airplane and handing it down to my family when the time comes.

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->