The commentary around the POH centered on operational procedures and how some things just aren’t in the manual. The other comment was that lots of airplanes don’t have a POH.

So, we have bad news and good news. The bad news appears to be that a swath of airplanes from experimental to vintage don’t have a POH. The good news is that most airplanes do have POH information; it’s just not assembled into a traditional POH.

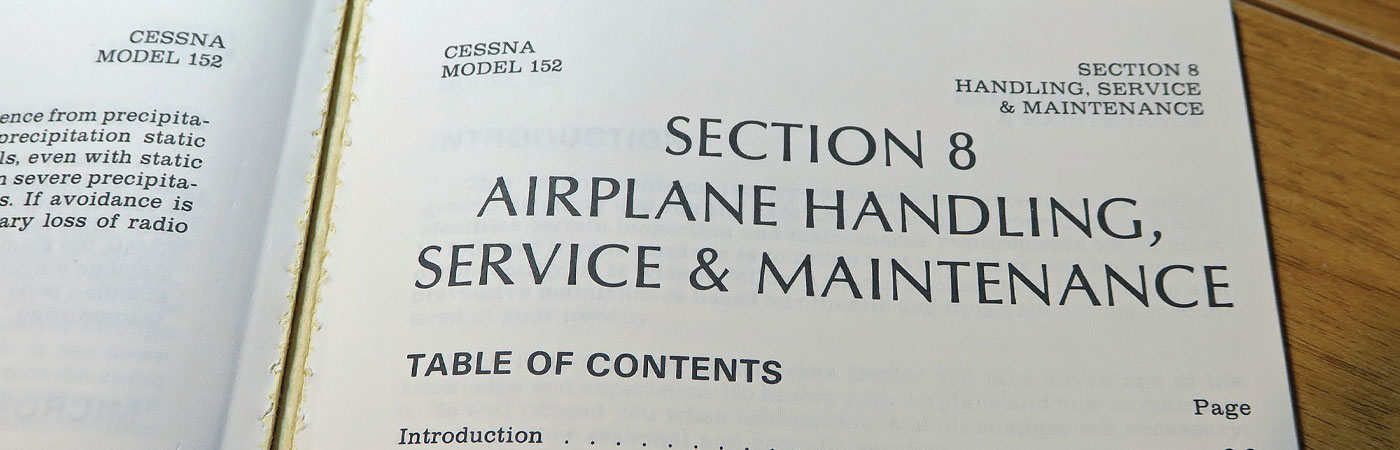

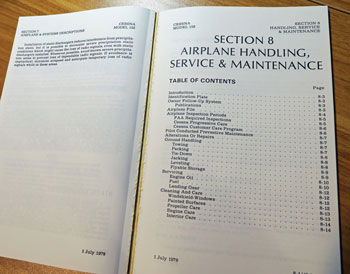

The other point I want to make about the POH commentary is that the wealth of information isn’t just for flight operations. It’s also for maintenance. One of the best places to find maintenance procedures is in the POH or PIM.

The part you don’t want to hear? I’m going to suggest you take the time to review all of your specific aircraft documentation and information to make sure that your airplane is legally airworthy, and then obtain or create the things you don’t have. This can include quirks you know about that aren’t listed anywhere as well as checklists that would help you with preflight inspections and operational procedures.

I mention this with spring right around the corner because now is a great time to get all of the information ready in preparation for another glorious flying season. Once it has warmed up and we’re headed to the airport, paperwork will be the last thing we want to deal with.

Rather than taxi off into the weeds about what type of manual you have, just remember that every airplane should have operating limitations and information on board (in addition to other document requirements). As the pilot for your specific aircraft, you will know what is required in the aircraft. See the sidebar on manuals.

In 2018, I wrote about how to make your own maintenance manual for your homebuilt aircraft (“No Manual? Write One!” EAA Sport Aviation, February 2018). What I’m proposing here is not as deep, but broader. If you need to create a maintenance manual for your homebuilt, check out the 2018 article.

While it is correct to say that many experimental aircraft do not have owner information manuals, well over half of the homebuilt aircraft kits today do have manuals and excellent documentation. It’s a big improvement over what we saw in the 1980s and ’90s. The best documentation comes from well-established manufacturers. Shining examples include Sonex, Van’s, and Kitfox. There are many others. You can expect good instructions and good — if not great — operating and maintenance information.

Whatever you are assembling or flying, here’s how to update what you have.

Set aside a day to pull out all your documentation. This can include:

- POH, PIM, airplane flight manual (AFM), or other general manual for the aircraft

- Manufacturer information and contacts

- Maintenance manual for aircraft

- Maintenance and information manuals for all components and accessories

- Engine maintenance manual

- Logbooks for the engine, airframe, propeller

- Warranty information

- Service bulletins

- Airworthiness directives (and for certified components)

- Preflight checklists

- Condition or annual inspection checklists

- Financial transactions

- Insurance information

If your aircraft is a homebuilt, you’ll also have assembly manuals or plans and the information the kit manufacturer gave you.

Next, determine what’s missing. Start with what makes the airplane legal to fly. This includes an airworthiness certificate, registration certificate, operating limitations, and weight and balance information. Make sure they are current. You can do this without taking them out of the aircraft — but do inspect each one.

Now look at the logbooks for the aircraft. Make sure the serial numbers match. Check for a current condition or annual inspection signoff. While much of this paperwork is checked on a condition or annual inspection, it’s a good idea to make sure everything is up to date now in this review.

Next, look at your checklists. Whether you’re using what you have in laminated form out of the manuals, such as a preflight checklist or a starting checklist, ask yourself if they can be improved. When I help builders assemble checklists for their homebuilts, we pull out a Cessna PIM and use the boilerplate. There is no reason to reinvent the wheel when you’re assembling this information. You just need to make sure it fits your specific aircraft.

If you’re assembling or flying a homebuilt with little information, I recommend pulling a good manual off the internet and using that template to improve your own. An excellent General Aviation Manufacturers Association (GAMA) style POH example is the now discontinued Cessna 162 Skycatcher. The manual is easily found online. You can download it and use it as a guide. Since it’s specific to the Skycatcher and copyrighted, you can use the format and topics because they are generic, but you don’t want to adopt it wholesale.

Ask yourself if there’s anything else you need. Do the checklists cover everything? Can the preflight procedure be improved? Are there any peculiarities that should be documented? Steve Krog, in “POH or No POH,” EAA Sport Aviation, December 2022, wrote about peculiarities he experienced with a Beech Debonair. A door opened in flight, and he could not close it. In talking to other pilots of the Debonair, he discovered that this was a common experience. This would be handy for another pilot to know before flying the Debonair.

Every machine has quirks. What are they? Write these down somewhere. If they are quirks like doors that cannot be closed in flight, or engine sweet spots for cruise, write it somewhere, even as a footnote. Homebuilts, in particular, may have peculiarities that distinguish them from the rest of the fleet. Document them.

If you’re flying an airplane with a POH, you can’t just add to it. The reason is that this manual must contain FAA-approved information, and it must be kept updated by the manufacturer. This doesn’t mean you can’t make up your own checklists for reference. Keep them separate from the manual in another binder.

You may find problems with your documentation and wish you’d never pulled all of it out. But from flight operations to maintenance, you’re going to be glad you got it all organized now.

Some benefits will be:

- You’re legal (“airworthy”)

- The annual (or condition) inspection will be easier

- Checklists will be up to date and include the oddities only you know about

- Enhanced checklists will improve safety

- You’ll know where to find everything

- The organization will help when it’s time for overhauls, restoration, or major changes

Performing maintenance, flying, and your pre- and post-flight inspections will be far easier if you have all the information organized and accessible. In trade for all the hours you spend to put this information together, you will thank yourself every time you use it.

Remember that accident data show us that the majority of aircraft mishaps are errors of judgment rather than mechanical breakdown. We can use the checklists and information available to reduce the chances that an accident will occur, both in the maintenance arena and in the operational sphere.

Finally, having all of your documentation organized and available for your specific airplane will add value to a future sale.

Don’t you feel better now?

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P mechanic, EAA technical counselor and flight advisor, and former designated airworthiness representative. She built and flew a Pulsar XP and Kolb Mark III, and is researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.