By Bruce Spears, EAA 1461375

I have noticed during my ownership of my Cessna 182E that sometimes little things can make big improvements in comfort and usability for me and my passengers. I have had a few passengers say how warm it can get in the back of the airplane during our summer flights; the sun coming in the back window can make the back seat a bit of an oven. So, I recently installed some DIY window tinting on the rear and side windows. So far, the results are well worth the time and small effort.

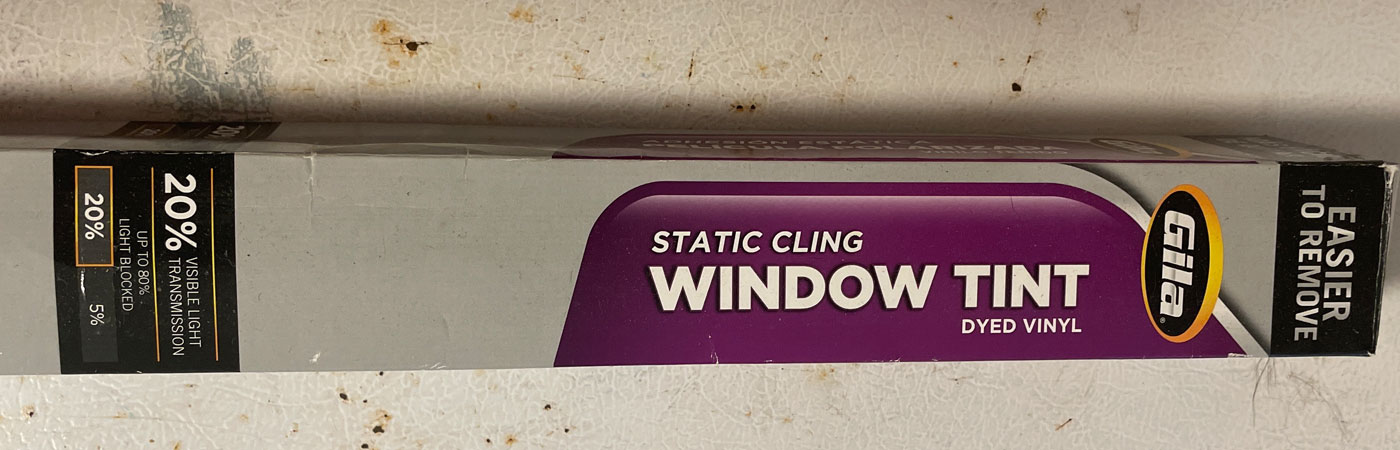

I had seen some products that are marketed for aircraft, but the cost seemed to be a bit high for my frugal tastes. Then I saw that a few owners of aircraft have used automotive tint film with success. I did a bit more research and found that using film for cars is an acceptable solution. But the films with an adhesive backing can react with and damage the Lexan aircraft windows. The solution was to find a “static cling” product that was acceptable to my project goals. There are lots of films marketed for different applications and tint levels, but I chose the easiest one for me to source the day I decided to try this project out. The film I used was an automotive product from the automotive isle at my local Canadian Tire. The product was a 20-percent limo cling tint. I think the cost of the product and the time it took to install it was a great upgrade in the ramp appeal of the airplane and for the comfort of my passengers. While not perfectly optically clear from the inside it creates a nice passenger environment inside.

I started with the flat easy to access rear side windows. My process was to fastidiously clean the window with plexus inside and out using a microfiber cloth. I repeated this step using a solution of water and baby shampoo. This is a recommended mixture to ease the installation process. I sprayed the outside of the window and tint film to make it adhere to the window. I placed a sheet of film on the outside of the window and traced the shape of the window around the inside of the frame onto the backing to get a template to cut from. After cutting to fit and testing a few times on the outside I moved inside. I sprayed the window with a generous amount of “soapy” water. I removed the protective backing from the film, sprayed it on both sides and attached it to the inside of the window. The solution of water makes the film easy to slide into position and enables you to lift it to make small cuts or adjustments. I then used an old hotel room keycard as a squeegee to press the film to the window and remove the fluid and air bubbles. I then dried around the edges with microfiber. The first window was completed in less than 20 minutes. The second took less time as I had the steps figured out. It was quite easy and I was impressed with my results. The nice thing about the cling film is that is easy to remove if you do not like the look, just peel it away. It leaves no residue or backing on the windows. The soapy solution is non-staining and dries up nicely.

The rear windows of my 182 have a complex curve that made it a bit more difficult to master the process of laying the film and cutting it accurately. Also, somewhere in its history it had some “repairs” with caulking that made cutting the edges to match the uneven caulk line a bit of a challenge. After doing the two flat windows I had a good idea on what to do. Tracing the shape was the hardest because the film had to adhere and not move as I pressed it around to conform to the curves as I traced. I was alone and this is where some painters tape to stick it better or a helper would have made the task a bit easier.

I watched a few YouTube videos to get an idea on the process, but most were dealing with automotive applications and recommended using a razor or an Exacto knife to cut the film on the glass. This would score the aircraft windows, so I used a nice sharp pair of scissors for my cuts and a sharpie to trace the window around the inside of frame. I cut it slightly larger to start then trimmed it down after a few trial fits. The process was easy and with a few videos watched I had the knowledge to try this myself.

The look of the tint seems to match the blue of the airplane along with the black trim. I have already got compliments on the job. For less than $50 and a short afternoon’s work it was well worth it. I didn’t have enough left over to make an “eyebrow” for my front windshield, but I intend to do this in the coming weeks. Due to the thickness of the film I used, it is not overly optically clear when viewed from the inside. I think it is pretty good for rear windows, I don’t think I’d put it on front windows or windshields that you need to look through constantly. Upon some further research I have seen that there is another product that may be better. It is marketed as an ultra version of the cling film, also there are several films for glass residential windows that may be another option.

I chose the 20-percent for its look but there are lesser or greater degrees of tint to use depending on your requirement.