By Wayne Roberts, EAA 840325

This piece originally ran in the June 2023 issue of EAA Sport Aviation magazine.

My RV-4 took to the air for its first test flight on March 17, 2022. Mike Skoczen, a friend who was a previous test pilot for Diamond Aircraft and builder of an RV-3 and a Harmon Rocket, along with a half-dozen other homebuilts, was chosen to do the honors. All went well with only a few adjustments made to the trailing edges of the ailerons and elevator. It’s now a “trim ship” without trim tabs.

This project started back in 2008 when I acquired a partial kit from a gentleman living outside of Celina, Ohio. It was then housed in the garage at our Cayuga, Ontario, home for the next 10 years. Nearly all the structural parts were constructed and fitted to resemble an airplane; however, in 2018 we moved to a much smaller location in Ancaster just west of Hamilton. The wings were removed, and the project was then moved to Binbrook, home of another friend, Adam Omasta, who incidentally has rebuilt several Stearmans and helped me restore my 1940 Piper J-3.

This project started back in 2008 when I acquired a partial kit from a gentleman living outside of Celina, Ohio. It was then housed in the garage at our Cayuga, Ontario, home for the next 10 years. Nearly all the structural parts were constructed and fitted to resemble an airplane; however, in 2018 we moved to a much smaller location in Ancaster just west of Hamilton. The wings were removed, and the project was then moved to Binbrook, home of another friend, Adam Omasta, who incidentally has rebuilt several Stearmans and helped me restore my 1940 Piper J-3.

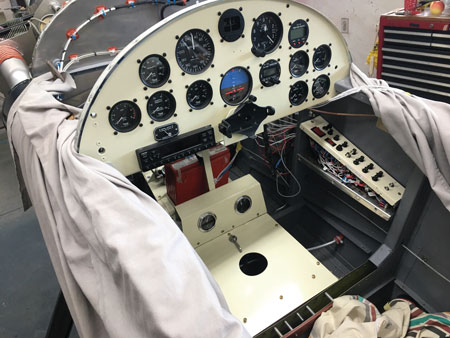

The RV-4 was metal prepped and received its primer coat. In 2019, the project was moved back to the Cayuga area and its current location thanks to another friend, Dave Bruce. The cockpit layout was completed including the wiring of all components and instruments. Prior to receiving my aircraft maintenance engineer license in 2001, I was lucky to have worked in an avionics shop picking up experience in trade practices and reading schematics. It was interesting how the wiring looked like a jungle at first, but after isolating the individual circuits and appropriate routing, the results and operation proved successful. On the engine side of things, I did the final securing of the carb heat, cabin heat, mixture, and all engine sending unit wiring at the firewall openings. Duct work for the oil cooler along with the magneto and fuel pump received special attention. On the engine baffling I was able to persuade the natural or intended curvature of the baffling by stitching the corners with black lacing tape/cord.

The last and final hurdle was the paint. It’s been a bit of a joke saying my airplane was going to be painted Deep Water Blue, and so I made sure I followed through and was able to obtain 1967 GMC Deep Water Blue, the same color as our first car after we were married. Although the formula is now lead free, it is the same metallic paint and shade. Part of Dave’s shop has been used as a paint shop for many airplanes as well as motorcycles. Needless to say with the price of paint, even automotive and all the necessary thinners and activators, I felt a little apprehensive even just adjusting and testing the mixture and spray pattern of the gun. This was my first paint job so having a backup observer and helper was more than appreciated. They say metallic paint application requires a little extra observation and scrutiny. If at all possible after you think you have it, look at it under different lighting (sunlight if available), and that could determine whether another coat is necessary.

The last and final hurdle was the paint. It’s been a bit of a joke saying my airplane was going to be painted Deep Water Blue, and so I made sure I followed through and was able to obtain 1967 GMC Deep Water Blue, the same color as our first car after we were married. Although the formula is now lead free, it is the same metallic paint and shade. Part of Dave’s shop has been used as a paint shop for many airplanes as well as motorcycles. Needless to say with the price of paint, even automotive and all the necessary thinners and activators, I felt a little apprehensive even just adjusting and testing the mixture and spray pattern of the gun. This was my first paint job so having a backup observer and helper was more than appreciated. They say metallic paint application requires a little extra observation and scrutiny. If at all possible after you think you have it, look at it under different lighting (sunlight if available), and that could determine whether another coat is necessary.

I was wrong. The last hurdle was putting all the painted pieces together, keeping the scratching to a minimum. All flying surfaces except the wings spent the late fall and winter months stored in the hangar loft to give the paint time to cure and harden up before being abused. Thanks to my friends who helped me. I think I’ll retire now.