By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the October 2023 issue of EAA Sport Aviation magazine.

Bianca had just finished 40 hours of flight testing on her newly built kit aircraft. As she signed off on the test phase, she thought of all the places she could go. She turned to her friend Eric.

“I’m ready to go someplace,” she said.

“I bet you are,” he said. “Hold on. I’d spend a little more time flying locally before you take off. Just because you completed your 40 hours doesn’t mean everything is perfect mechanically.”

“But I’m itching to go somewhere,” Bianca said. “I won’t go far. A day trip.”

Bianca cocked her head and smiled. “I might even invite you to come along.”

Eric laughed.

“I get it. Bring your A&P with you on your first trip. Actually, it’s not a bad idea. Okay.”

Bianca was full of pride and excitement. It was a dream come true. But, like many first-time aircraft builders, she was nervous and hoped her inspections had been adequate.

They were almost home when the smooth hum of the engine turned rough and choppy. Then it stopped. It was so fast that it took both Bianca and Eric by surprise. They voiced “checklist” into the intercom at the same time.

Bianca instinctively switched tanks and then turned the key as she reached for the checklists. The engine fired back up. Her hands trembling, Bianca started a slow and steady climb to give them some opportunity to troubleshoot.

“Fuel,” Eric said. “Let’s get on the ground. We’re lucky to be so close.”

They landed without problems and taxied to the hangar.

“Let’s look at your tank filters,” Eric said.

Bianca grabbed a screwdriver and removed the left cover from the side of the fuel selector housing. She removed the filter from the tank that had failed.

“Just what I thought,” Eric said.

He held the filter up to the light. Pieces of fiberglass and debris fell out of the inlet side.

“Why didn’t I catch that?” Bianca said.

“It’s easy to miss,” Eric said. “Don’t feel bad about it. Just add extra inspections and more frequent filter changes. Since this is a composite airplane, there’s all kinds of junk waiting to leave the tanks. Just be glad you have two tanks sending junk at different rates.”

* *

As a builder, you know that the first few hours of operation are critical. We usually say the first five to 10 hours are going to contain intense inspections of specific areas. Then, the rest of the 25 or 40 hours you put on the airplane are focused on flight testing and calibration.

But once you sign off on your test phase, the work is not over. Here are the areas to pay attention to.

Systems and Components

Several years ago, Ron Wanttaja, EAA 275698, assembled a classic analysis of homebuilt accident rates. Forty-eight percent of the homebuilt accidents involved errors in kit workmanship and component installation.

This is not surprising, given the unique characteristics of each build. There can be a lot of variability in the kit instructions. Manufacturers with many kits flying tend to have better documentation, and quick-build kits have more ready-made component assemblies, making it easier for the builder to get things right.

While everything should be inspected, I have seen the most problems with fuel systems and electrical assemblies in the first 100 hours of homebuilt operation. Here’s what to look for.

Fuel system. Like the plumbing in your home, if your airplane’s fuel system is not correctly assembled with the right materials, it will clog or leak.

- Are you using fuel hoses recommended by the manufacturer?

- Are hoses and fittings secured against vibration?

- Are fuel system wires labeled for troubleshooting later?

- Are filters in the right place and the type recommended by the manufacturer?

- No matter how clean the fuel tanks are, they will generate debris in the first hours of flight. What surprises us is that it may continue for quite a while.

- Perform thorough fuel sampling before flight. Follow the directions from the manufacturer.

- Pay attention to fuel sensor calibration to verify it’s correct after Phase I testing.

- Is your airplane sitting idle for weeks at a time? After that whirlwind test phase and the glow of the flight hours after testing, the airplane may sit. If it does, pay attention to the fuel if you use autogas. Purchase premium fuel without ethanol for reliability and longevity.

- If you’re running 100LL, look for blue stains on your inspections. These stains are a sign of a possible leak.

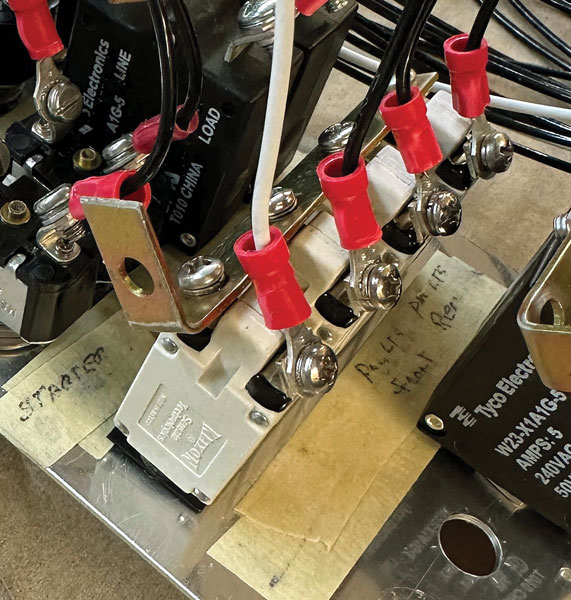

Electrical system. The insidious thing about electrical system components is that they are subject to failure from vibration if they are not fully secured. As a designated airworthiness representative, I used to pull lightly on electrical assemblies to the dismay of the onlooking builder. Would you rather have it come apart on the ground in an inspection or in the air? I’m not telling you to pull on all your electrical connections, but make sure you’re using the right terminals and tools. Electrical failures are no fun.

- Label the wires where they attach to the power bus and other components.

- Follow directions carefully for grounding. Multiple grounds can create a host of problems, including radio noise.

- Make sure terminals are correctly attached. Ask an A&P mechanic to advise you if you’re not sure. Get training if you’re not experienced. Use ring terminals where you can — they don’t slip off unless the screw comes all the way off. Yes, it’s more time-consuming.

- Secure wire bundles from excessive vibration and use standoffs where the bundles may chafe.

- Protect wiring from hot areas of the engine and exhaust components with fire sleeving.

Habits

I’m an advocate for developing good checklists that drive thorough inspections. But I’ve found that there’s one characteristic in attentive builders that stands out more than any other: good habits. If you develop good habits around maintenance and inspections, your chance of having an unwelcome surprise will considerably decrease. Here are some areas to consider.

- Preflight

- Preflights should be driven by conditions. If you’re hopping in after your $150 burger (inflation), think about the things that could have changed within the last several hours. Did you fuel the airplane? Check the security of tank caps. Check the fuel for contaminants. Any anomalies landing? Check tires. Any handling problems? Check to make sure baggage or cargo is still secure.

- If you’re getting ready to go on a longer trip, make your inspections more thorough. Also, think about what items to take with you in case you get stranded.

- Post-flight

- Most pilots dispense with post-flight inspections because they don’t think they are necessary or they do not want to take the time. My suggestion is to do a post-flight but tailor it to your airplane. Focus on things that could have changed during the flight.

- Stand back from the airplane and observe it before leaving it. Look for leaks. You will sometimes find some strange things and be glad you looked. It doesn’t have to take long. On one trip of mine early in the flights of my first homebuilt, everything seemed fine until I stood back from the airplane before pulling it back into the hangar. A line of oil covered the underbelly of the airplane from the exhaust tip at the engine cowling to the tip of the tail. I had overfilled the oil tank. No harm done, but I was glad I noticed it and cleaned up the mess before putting the airplane away.

- Checklists

- My favorite tool. These can be out of the pilot’s operating handbook (POH) or a combination of lists you have assembled from the manuals. Ask the builders’ group members for what they have. Most of the groups will assemble the best tips online for others to use. You can also record your lists and use audio as you do the inspections. If you want to get fancy, a variety of apps can provide you with custom question-and-response sequences.

- I have found the best checklists are custom ones you assemble for your particular airplane, with bold text for the items that are most important. These will vary with the airplane type and complexity. As you put more hours on your airplane, these checklists will get better and better. The one thing I would never do is skip a checklist because “you know everything is okay,” or “I know this by heart.” That will be the one time you miss something important.

- POH or PIM

- Assemble your POH or pilot’s information manual (PIM). Many of the well-known kit manufacturers have a POH/PIM that comes with the kit that you may be able to improve upon. However, many manufacturers do not supply any formal handbook. Assembling your own will be the best thing you can do. I’ve had readers send me some of their work, and it’s outstanding.

- Logbooks

- Make sure they are updated and accurate. Along with the weight and balance, operating limitations, and airworthiness certificate, the logbooks will make your airplane an easier sale if you choose to part with it at some point. They also make inspections easier. Periodically check weight and balance since airplanes tend to get heavier over time.

- Socialize

- Don’t be afraid to get help. In addition to a technical counselor and flight advisor, ask the local experts to look at your airplane. They will always find something you didn’t see.

The first 40 or 50 hours flying your new homebuilt are intense. Now that you are headed toward your first 100 hours and beyond, don’t let your guard down. That exhilaration generates the energy to continue to be thorough in your inspections, developing habits that will serve you through many more hours of safe flight.

Lisa Turner, EAA Lifetime 509911, is a manufacturing engineer, A&P mechanic, EAA technical counselor and flight advisor, and former designated airworthiness representative. She built and flew a Pulsar XP and Kolb Mark III and is currently researching her next homebuilt project. Lisa’s third book, Dream Take Flight, details her Pulsar flying adventures and life lessons. Write Lisa at Lisa@DreamTakeFlight.com and learn more at DreamTakeFlight.com.