By Ben Davis, EAA 1329571

This piece originally ran in the March 2024 issue of EAA Sport Aviation magazine.

The goal was a comfortable and streamlined gyroplane to replace the scratchbuilt, open-air machine I originally purchased from my instructor to solo and earn a sport pilot certificate in. I very much enjoyed the thrill of flying completely exposed, but several years of removing bugs from my visor and flight suit had me searching for something more appropriate for my wife and I to frequent Carolina fly-ins and search for $100 gluten-free burgers. There are many sporty and proven gyro kits available these days, but I chose the AutoGyro MTO Classic as the best match for our budget and performance needs, while still retaining the “motorcycle-of-the-sky” experience of an open cockpit. We visited CFI Greg at Rotors Over Rocket City in Huntsville, Alabama, for our orientation flights, whereupon my wife gave the MTO a muted thumbs-up.

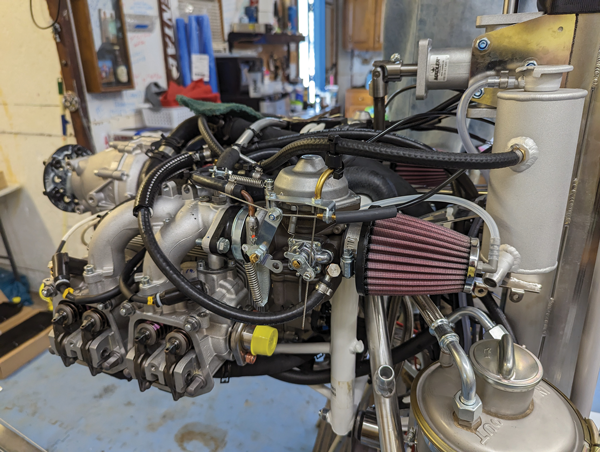

Reading EAA Sport Aviation and attending EAA AirVenture gave me confidence that I could safely build an aircraft with professional oversight. I chose an AutoGyro builder assist location in Blum, Texas, and began the approximate six-month wait for my kit to be prepared and shipped from Germany. I decided to go with “steam” cockpit gauges, adding a f.u.n.k.e. AVIONICS transceiver, uAvionix ADS-B In/Out system, Velcro-mounted iFly 740b, and Lightspeed Zulu headsets. For engine options, I chose the standard 100-hp Rotax 912 ULS, plus a 15-hp “big bore” upgrade kit to provide extra power for hot, humid conditions.

Fast-forward several months to March 2023 and I am settling in at the bunkhouse at Fainting Goat Airport (87TX) in Blum, stocking the fridge with groceries and buckling down for what would become two weeks of 12-hour workdays. I arrived just in time for a barbecue fly-in of gyroplane pilots and enthusiasts from several states, all of whom were supportive and encouraging about my upcoming endeavor. Craig and his team at Blue Skies Gyros were kind and helpful throughout the build and testing process.

After a shop orientation and parts inventory, I began the 51 percent assembly process that started with a bare, stainless steel frame. All instruction manuals and diagrams were available as digital PDF files on the shop computer, but it was nice to have Craig and his son nearby to provide clarification and helpful tips. For those interested in the day-by-day assembly details and pictures, you can find my builder’s log on the EAA website. Approximately one week into the build, my two brothers flew in from the east and west coasts to participate in the fun. We focused on the engine installation and rebuild, which was completely new to me. It was a multiday effort, interrupted only by traditional Texas dining excursions and a couple of MTO orientation flights to help them share in the excitement. After an evening campfire on top of a converted grain silo, my brothers returned to their respective coasts and left me to finish the task. I will be the first to admit that I had the “privilege” of performing several of the assembly steps a second time, but I gained a much better understanding of the airframe in the process.

As my time in Texas wound to a close, I received several MTO training flights and worked to get the aircraft prepared for shipment to South Carolina. Next stop: Fairview Airport (33A) via a flatbed trailer for final assembly and testing.

A couple of weeks later, Craig and his wife delivered the gyro to South Carolina and assisted me in attaching and aligning the rotor blades. The next few weeks were spent in final finishing. Special thanks to James at AeroGraphics.com who helped me design a classic South Carolina palmetto logo with matching N-number and swooshes. The designated airworthiness representative had reviewed my online EAA builder’s log, so the airworthiness inspection was uneventful. Finally, my initial instructor was kind enough to help me with propeller adjustment, the engine pull test, flight angle checks, and first flights. After numerous taxi and prerotator system checks, plus many runway trips in flight attitude “balancing on the mains,” the first flight in May 2023 was both exciting and successful. That was followed soon after with solo and test flights using the EAA Flight Test Manual and applicable test cards.

I have since completed the 40-hour fly-off and visited several fly-ins and airport cafes, some with my beautiful wife. Our favorites were the friendly Long Island Airpark (NC26) open house, a tasty South Carolina Breakfast Club gathering at Spartanburg Downtown Memorial (KSPA), and the ever-famous Triple Tree Aerodrome (SC00) fall fly-in. Shortly thereafter, I packed my camping gear, donned an insulated jacket and gloves, and flew over the Smoky Mountains to meet a couple of fixed-wing buddies at Elizabethton Municipal (0A9) in Tennessee. Aside from some unexpected valley fog on the initial leg over Asheville, it was an epic weekend of mountain flying and outdoor fun.

Overall, this gyro build stretched my comfort zone and allowed me to meet many helpful people, to whom I am very grateful. I was initially hesitant to embark on such a journey in my 50s, but the resources made available through EAA made the task feel surmountable.

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->