By Vic Syracuse, EAA Lifetime 180848

This piece originally ran in Vic’s Checkpoints column in the September 2024 issue of EAA Sport Aviation magazine.

I know there’ve been a few different columns interrupting this story on maintenance for reliability, but hopefully you found them worthwhile. As a refresher, at the end of Part 2, I was trying to figure out how to upgrade the panel in the RV-10, which currently had Advanced Flight Systems 5400s installed.

Luckily, I was successful in convincing Carol that the upgrade was a good idea, and I would place an electronic flight instrument system directly in front of her, which would eliminate the need for her to use an iPad. She likes to pan and zoom the map to figure out various landmarks as we fly along.

Panel upgrades are not something that you decide one day and start working on the next. They require some planning and coordination with the various suppliers, such as choosing and acquiring the actual components, powder coating and engraving the panel, and scheduling the downtime for the aircraft.

I usually plan on two to three weeks of downtime, depending upon the scope of the upgrade. The first week is usually consumed by carefully removing all the existing equipment and labeling all the existing wiring. In this case, since I knew the airplane quite well, I hoped I could finish in two weeks or less.

The weather in January is usually not conducive to flying, so I decided in November and confirmed with Rob Hickman, EAA 424007, at Advanced Flight Systems that he could ship the new AFS 6600s in January. I needed only the screens and not all the ancillary stuff behind the panel, as I would be reusing most of it.

Right away I began working on the layout of the new panel. I’ve always used the Panel Planner software for this part of it. It’s easy to use and creates the DXF file that I can send to AFS. The 6600 screens are a little bigger than the 5400s, so it took some time to move everything around such that it would all fit in the new configuration. The 5400s were configured side by side with the stack of avionics off to the right.

The new configuration would put the screens on either side of the panel with the avionics now closer to me. While I liked the avionics being closer to me, as it lessens the angular view, I was going to miss having one full screen in front of me dedicated to a map function. I really like the Aerosport panel that Rob has in his RV-10 that places a larger map screen in the middle, but I didn’t want that extra expense right now, nor did I have time for all the major modifications that panel would require.

(Interestingly enough, after I installed the panel, I found a neat feature in the AFS software. If the map view is eliminated on the left screen, and the right screen is in full map mode, you can remotely zoom the right screen from the left screen knob! Since most of the flying in my RV-10 is by myself, it works out nicely. But I still have my eye on that three-screen panel. One day perhaps. Dreams are what keeps us going!)

The other nice thing about Panel Planner is that you can print out full-size drawings of the panel as you work through various renditions. I do that, tape it on a wall, and sit in front of it to mimic the cockpit setting. It’s amazing the things you realize won’t work, as well as the things you’ve forgotten about. I think it took about five different tries before I got it the way I wanted it. I also had to be cognizant of the impact of moving things around on the front panel affecting the substructure behind the panel.

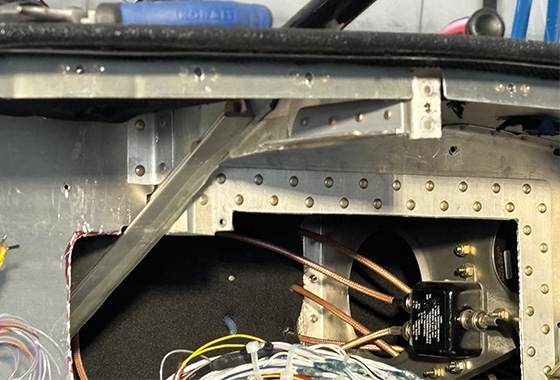

As an example, in the original panel, the Sorcerer autopilot was at the bottom of the stack, where I preferred it. The Avidyne 550 was right below the audio panel, which is standard practice. This all worked fine when the stack was off-center to the right. Moving it to the center now caused interference with a structural member. I found myself with a couple of choices.

The Sorcerer autopilot is no longer sold or supported. Perhaps I should just eliminate it and go with an integrated autopilot. The integrated autopilot would require new servos and some extra wiring. Not a really big deal, but I do like the backup capabilities of a separate autopilot. In the case of the Sorcerer, it’s easy to have it fly a fully coupled approach via the front panel.

After staring at it for a while, I realized the Sorcerer was much shorter in length than the Avidyne, and if I placed it between the audio panel and the Avidyne, it would give me the clearance I needed with the structural member. So, that was the decision I made. Of course, with every change comes downstream changes. In this case, I needed to make a 37-pin extension cable and reroute some pitot-static lines. It all worked out okay.

One of the additions I made to the panel was the installation of the autopilot control head. It is now much easier to change modes, such as changing from HDG to NAV mode with just a press of a button rather than bringing up the autopilot menu in the electronic flight instrument system (EFIS). Then, when/if it comes time to add the integrated autopilot, it will be just a matter of adding the wiring and servos.

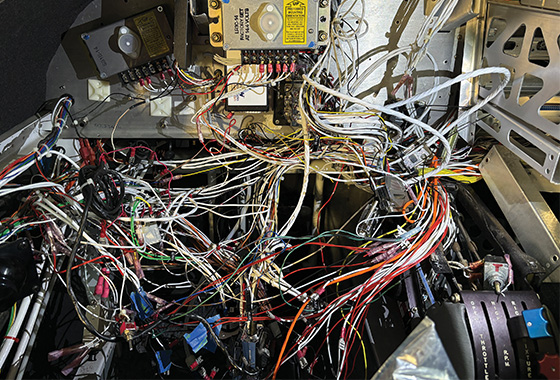

Once shipping dates were confirmed, I started to disassemble the panel. I had another reason for doing this project. Over the past 15 years and 2,500 hours of flying, I have had multiple kinds of equipment in and out of the aircraft. Everything from different ignition systems, different EFISs, weather systems, ADS-B, etc. It was time to remove all the excess, unused wiring and label/secure the rest of it properly, With the panel completely removed, this task should be easier.

As you can see from the picture, it was a mess that I was not proud of. Every time I had a reason to look behind the panel it reminded me of the cobbler’s children. I was tired of it. Suffice it to say, it is now all nicely organized and labeled with heat-shrink wiring labels.

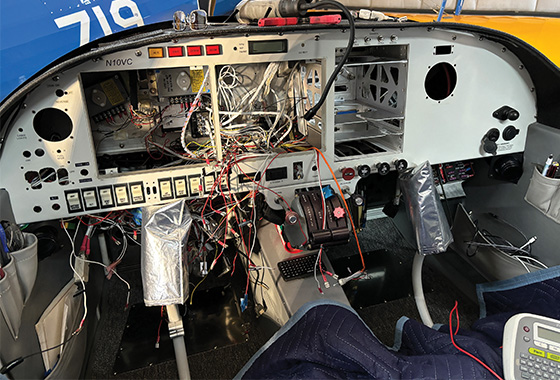

I like to preassemble the panel with the avionics on the bench prior to installation in the aircraft. Doing that allows me to verify everything fits, and then verify there is no interference with the subpanels. I also upgraded the TCW backup battery from a 3-amp hour unit to a 6-amp hour unit so that it would power both EFIS screens. The battery in the emergency locator transmitter control unit was also replaced with a 10-year Duracell battery. I also reinstalled the XM weather receiver for future Alaska trips.

There’s always apprehension when it is all finally installed and power is applied. My practice is to leave all circuit breakers/fuses either open or uninstalled and then add power to each circuit one at a time.

In this case, it was uneventful, and the smoke stayed in the wires. Usually, a panel upgrade takes a full day configuring everything to talk with each other once it is installed, but not so in this case. The team at AFS takes your current configuration files and installs them on the new screens.

It was exciting to see it all work together so fast. I did let it bake in with power applied for multiple hours across a couple of days, and then test-flew it. It was flawless and has continued to be so for the subsequent 45 hours!

Carol convinced me that she wanted to redo the interior while I was doing the panel. How could I refuse that offer? It came out spectacularly as well. I will detail it in the next column. Right now, the added upgrades have added to the fun factor.

Vic Syracuse, EAA Lifetime 180848, is a commercial pilot, A&P/IA mechanic, designated airworthiness representative, and EAA flight advisor and technical counselor. He has built 11 aircraft and has logged more than 11,000 hours in 75 different types. Vic founded Base Leg Aviation, has authored books on maintenance and prebuy inspections, and posts videos weekly on his YouTube channel. He also volunteers as a Young Eagles pilot.