By John Klassen, EAA 781675, Headingly, Manitoba; Lyncrest EAA Chapter 63 member

Who doesn’t like hearing about stories from WWII where the P-51 pilots were the aces that turned the tide of the war? I have been to Oshkosh several times over the years and met several great P-51 pilots. Some of these great pilots were Bud Anderson at his book signing, age 100, and Colonel McGee at age 100 at his book signing! We were fortunate to see the movie Red Tails as well, which is about African Americans flying P-51s in WWII.

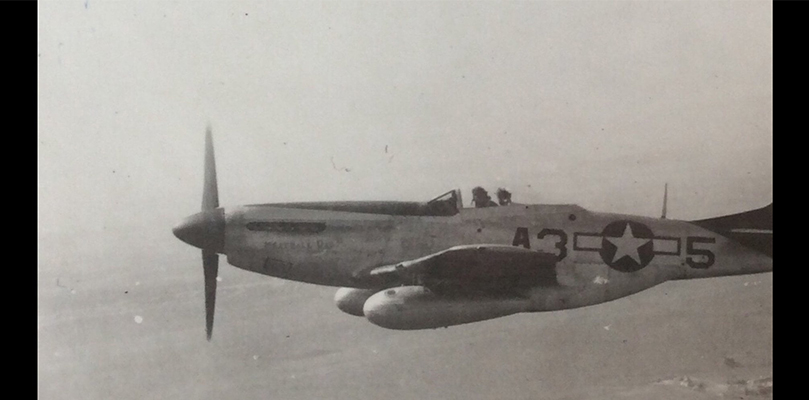

Tuskegee Airman Charles Lane was an escort in a P-51. The pilot of the P-51 and the cameraman on the B-17 were able to get together after the war. He eventually became a Lt. Col. in the 332nd Fighter Group.

In 2018, my wife and I invited our daughter, her husband, and their baby girl to join us in Oshkosh. They would be guests in our camper and share the meals in the woods with us and other Canadian campers from Chapter 63. My daughter, granddaughter, and I were walking around and looking at the different displays. When she spotted a display of pedal planes from Aviation Products, who were selling plans and kits to build them, my daughter asked me if I could build one from the plans that were for sale. These pedal planes are similar mechanically to the John Deere pedal tractors or the pedal sports cars of years ago. I said to her, if I built one, which plane would be your favorite? She answered, “I like the way the P-51 looks!” I said that is my favorite plane as well. My wife thought that between the two of us we were skilled enough to build a pedal plane for our granddaughter and any future grandchildren. My wife Kathie has made several different toys and puzzles from a variety of different hardwoods and is very creative. I was a heavy equipment mechanic for 13 years and then returned to school to become a certified mechanical engineering technologist.

I didn’t buy the plans right then, but thought I would go back later without my daughter’s knowledge. Later on my wife and I bought the plans and safely tucked them away until we returned home to Manitoba.

I started studying the plans more carefully after I retired in January 2020. Then COVID-19 took the world by surprise! There were a lot of changes in our lives because we didn’t understand the full depth of what COVID-19 could do to us. I was at home, but my wife was still working as a transit bus operator, which was an unrecognized frontline role! This in itself was a stressful time, so it was good that I had a lot of projects to keep me busy. With a lot of stores closed and the supply chains shut down, I started to make the mechanical mechanism for the pedals, the steering mechanism, the yoke, and drive train for the propeller. The pedal plane parts that were made from steel according to the plans were made from pieces of steel I had at home. I used my milling machine to machine the jig for the crankshaft and then used my oxy-acetylene torch to heat the steel so I could bend the rod and form the crank. There were a couple of parts for one of the wheels and the spinner that required welding a nut to a washer, and I chose instead to model those parts in my CAD/CAM program and machined them as a single assembly on a metal lathe converted to CNC control. When I ran out of steel parts to make, I used the CAD/CAM program to model the hubcaps and the grip for the joystick and then printed them on a 3D printer. The spinner profile was also modeled in CAD, and to get the correct size, I used 3/4-inch-thick spruce boards stacked together, as shown in the plans. Once they were glued together and clamped for a day, I machined the spinner profile on my CNC Southbend metal lathe.

There were instructions printed in various places on the drawings, and while you are supposed to cut out each of the full size parts, I chose to trace each of the parts onto separate sheets of paper and then cut those out to trace onto the plywood panels. I elected to use Baltic birch plywood thinking it would provide a superior finish. However, it turned out that the thinner layers of the Baltic birch created a problem with delaminating when I went to bend the side panels. I decided that I had too much invested in the wooden pedal plane to start over. My wife suggested outdoor carpenter glue to glue the plywood layers back together and clamp them in a fixture to keep the shape. That worked much better than I expected. I had all the different parts almost completed, so now we could start assembling our P-51.

I started assembling the wooden parts and decided to go to an auto body shop to get it professionally painted, based on a picture of a Tuskegee Airmen P-51 escorting a flight of B-17s we found on the internet. The independent auto body shop owner did not have the time to paint it right away, and we expected to pick it up in about a month. We didn’t expect that 10 months would go by and he still hadn’t called us. Kathie finally got in contact with the auto body shop owner, and he told us it had been finished for a long time but he had lost our contact information. The paint job was much less professionally finished than we expected. He had only used a spray can of silver paint to represent aluminum and had not painted the red on the tail, the yellow stripes on the wings, or the olive drab on the hood. We finished up those details ourselves with Tremclad spray paint. We did purchase a decal kit from Aviation Products and finished assembling the complete P-51 by the summer of 2023.

The first “pilot” to pedal it around outside was my niece’s 4-year-old son. He was very coordinated and could pedal and steer. Soon his little brother, who was 2 years old, wanted to try to operate the P-51, so with pillows stuffed behind him in the pilot seat, we helped him get into the cockpit. There he tried to reach the pedals, but he was too little. So we pushed the P-51 around as he giggled!