By: Jay Thorburn

Earlier this year while flying back home from Vernon, British Columbia, I reached into my bag and pulled out the latest issue of EAA Sport Aviation magazine, which I had snuck from my father’s hangar. It had been ages since I’d last read one of these magazines, but the articles about aviation enthusiasts — people who shared my father’s enduring passion — offered a familiar comfort.

Luckily, since my father had been a member of EAA since 1974, these magazines were all over our house and hangar for as long as I can remember. During my childhood in the ‘70s and ‘80s, the kit aircraft world became more mainstream, and by my teen years I had taken a real interest in the articles on different designs and aircraft builds. But on this flight from Vernon, I was drawn to the Member Central section near the end of the magazine, filled with information about hobbyists and their latest projects.

Rick Thorburn, EAA 83949 — my father — passed away in the spring after a life marked by an enduring interest in all things related to aircraft. He helped shape the CYVK airport in Vernon. In the early 1980s, he acted as Regional Airport Commission Chairman with the $500,000 runway extension. Over the years, he was president of the Vernon Flying Club and served on the BC aviation council, but his biggest influence was on the local flying community. The last 30 years of his life were spent as an avid builder of Van’s kitplanes, a passion that brought him a great deal of knowledge, adventure, and friendship.

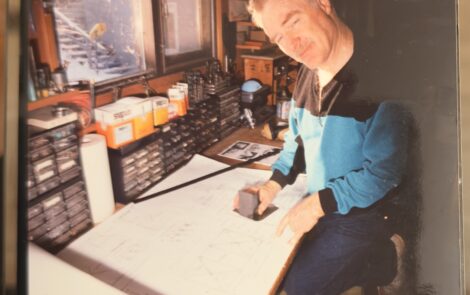

Since he was a little kid, my dad was a huge fan of anything that flew. In the early 1950s, he started out with scratchbuilt control line aircraft, relying on photos, magazines, and his imagination. He came by his fascination honestly: his own father was an aviation radio-navigation instructor during WWII, spending hours in the back of a Noorduyn Norseman, and eventually devising a push button remote controller for the aircraft. My father would have loved to become an airline pilot, but his colour blindness took a commercial licence out of the question. Instead, he attended the University of British Columbia and pursued a career as an architect, eventually practicing all over BC and Alberta from his home office in the Okanagan.

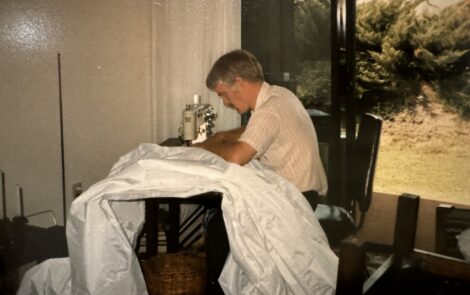

Though architecture was his career, aviation remained his passion. In 1976, he started on his pilot’s licence, and by the early 1980s, he had bought his way into a third-ownership of an Aeronca Champion 7GC. It had heel brakes and was in desperate need of a fresh fabric covering. After a few years, he was able to buy out his partners. This is where the transition started from working on RCair planes to real, full-sized aircraft. The shift brought change to all parts of his life, from developing sewing machine skills to bringing real aircraft parts into our family home!

Over time, my father was able to bring his passion for flying into his “day job,” saving time traveling to job sites around western Canada, turning multi-day trips into single-day trips, grinning ear to ear while flying his freshly rebuilt aircraft. Sure, he faced challenges: not being able to land in 30-knot crosswinds at destination, dog vomit down the side of the airplane, and being way too low in mountain passes during times of “get-home-itis” as he wasn’t able to hold a night rating. But that was all part of the adventure.

My father soon set his sights on a Stinson 108 and flew that, as well as the Champ, for years. I’ll always remember eating caramels from the old coffee tins behind the backseats to ward off motion sickness. Yet, I marveled at how smooth the controls were in that airplane as the old Franklin engine cranked along. I remember watching him loop the old Stinson on the downwind as he came into land. Unfortunately for my dad, the Stinson didn’t have enough issues to require a long-term overhaul, so he moved on to a completely different project (though his dream of a 108-3 never came to fruition).

A Luscombe 11A was up for grabs after a ground loop in Revelstoke, British Columbia, and my father brought it home on a trailer. This introduction to working with aluminum influenced my dad for more than 30 years afterwards. But since he was working on a budget, the big-ticket items such as an engine rebuild and a bent spar were a bit too much for him, and he eventually sold the aircraft to a gentleman south of the border.

From the sale of the Luscombe, the timeline of my dad’s various aircraft projects gets blurry, probably because his passion intensified. He loved to have at least two projects on the go, getting bored and flip-flopping to other projects. CF-JSY or Jessy was a Piper PA-12 Super Cruiser purchased on wheels, but a dream of having it on floats had to be fulfilled. All of this had to be done on a budget. Three sets of wrecked CAP 2000s floats in various states of destruction were dismantled and reconstructed into one serviceable set. New float fittings were attached to the fuselage, and a silver spray bomb primer aircraft paint job was thought to have completed the project. But with a hot Okanagan summer completion date for the flapless PA-12, and a few arduous takeoffs, the O-235 was soon replaced with an O-320 and a borer prop. I had the chance to fly this aircraft for a few years, and, hands down, it was the most fun I have ever had in an airplane. No radio, no bells and whistles, just bare bones stick-and-rudder fun.

During the 1990s, my father’s hobby switched from working with classic taildraggers to building his first Van’s RV-6A. He was drawn to an “A” because it was an aircraft anyone could fly, and he noted that the taildragger experience of the average pilot was dwindling. He started building in the shop at our house, leading to parts and pieces being strewn all over the place, including metal shavings in the carpet. By the time I was a teenager, the sound of my father’s rivet gun from the shop had turned into my personal alarm clock. It wasn’t uncommon for me to bring a friend home, only to tell them to watch out for the propeller in the hallway, or not to sit on the tail kit on the couch. At one point the fuselage was on our dining room table! Dad estimated 3,000 hours of build time from kit to finish. The “Thorburn finish” on C-FXLC, or “LC,” included extra drilled-out holes to save weight, an additional dorsal fin ahead of the vertical stabilizer to reduce waddle, side fuselage inspection panels for accessing behind the instrument panel, and all-metal front window mouldings to replace the factory fibreglass. My father loved the military-style slider canopies and trying to keep the aircraft light. With a 150-hp O-320 and an over-coursed fixed-pitch cruise propeller, LC’s cruise was 150 knots, never reaching engine red line and almost always running flat out.

When one project ended, the other was right around the corner. My dad’s love for flying was matched, if not surpassed, by his love for building metal aircraft. He was always intrigued by flying boats, and this pushed him to design and build a complete fuselage for an aluminum single-engine pusher-style flying boat based on Van’s RV components. He eventually ditched the build due to theoretical stability issues, and possibly because of his lack of strength as a swimmer.

Over the next few years, he purchased and built an additional RV-6A kit. RV number 2, or “VTJ,” had an engine upgraded to a 160-hp O-320 and a less course fixed-pitch propeller, as well as a professional paint job and a clean leather interior finish. This was a really well-built aircraft — a bit of a cream puff. My dad’s trend of building one project and having one flying aircraft continued for many cycles.

RV number 3 was the first RV-7A. My dad avoided scratching any metal surfaces, aiming for a polished warbird finish. “AKO” was its registration but it was referred to as the Silver Bullet, as this aircraft received an IO-360 208 hp engine and a big fixed-pitch propeller. It climbed like crazy with the big engine and the lighter weight of the fixed-pitch prop. My dad didn’t keep this aircraft for long, as he was worried that higher-octane fuel would soon be unavailable.

At one point, he picked up an old ex-Canadian military 182D model, and even a Lake Buccaneer LA-4-200. The 182 sat for years and was never worked on, but my father cleaned up and eventually sold the Lake prior to receiving a new paint job.

The next build was number 4, “AJE,” the one and only RV-8A with a 180-hp O-360 and another fixed-pitch prop. This aircraft was painted bright yellow with a black lightning bolt like an old Cub and finished with a military green interior finish. It was an absolute hot rod and a joy to fly. The aircraft was well matched to the 180-hp engine. My father loved everything about it, but the excitement of flying with a friend was lost due to the tandem configuration. His preference to have someone beside him to enjoy the experience of flying was a clear sign of my father’s selflessness. He loved to take people flying and teach them how to build these aircraft. More often than not, his hanger became a social gathering of local RV builders either looking for answers or giving a helping hand.

As RVs came and went, the builds continued. His final project to completion was RV build number 5, “RVJ,” an RV-7A. It was a great experience having a fixed-pitch 180-hp Lycoming like his previous build, along with a Dynon Skyview, Garmin G5, ADS-B, and Dyson autopilot. But my dad was starting to age, and his name is only in the logbook a few times. Eventually, he lost his aviation medical, but his passion for building remained. A friend of his would fly the airplane and my father switched gears to a new idea.

After seeing the propulsion changes in the radio-controlled world with the introduction of lithium polymer batteries and DC motors, his idea was to help general aviation switch gears into an electric age. He dreamed of having an electric-powered Van’s RV-9A. This aircraft build was finished past a point of 50 percent, but my father was starting to depend on others to make it happen as his health declined. Instead of daily trips down to the hangar, he transitioned to weekly visits with the help of friends and family.

But in my dad’s last years, he created many drawings of different layouts of DC motors, voltage and amperage calculations, reduction gearbox designs, battery layout sketches, and weight and balance calculations. His goal was to utilize two or more DC motors with individual battery combinations for redundancy. His first set-up was two smaller DC motors, battery controllers, a belt drive reduction gear system, and a wooden ultralight propeller. This was run and tested on a PA-12 airframe as the testbed. Calculations were estimated at almost 100 hp, fine for a J-3 Cub, but not for an RV-9A. We all told my father that under no circumstance would we sit in an electric airplane with a belt drive system, so it was back to the drawing table for a larger system.

The second propulsion system used two 65 KV brushless DC motors and a custom milled reduction gear box made by a local millwright. This would generate enough power to fly an RV-9A, while using an engine design to keep the original RV cowling and conical engine mount for the aircraft. Before my father passed away, his friends joined together and helped him finish off the electrical setup of this larger engine design with its motor controllers and battery hook-ups. They were able to get the system running, putting a big smile on my dad’s face. It never made it into the RV-9A, but hopefully one day soon someone will be able to finish my father’s dream project and introduce the world to an electric homebuilt Van’s RV.

During my father’s “aviation career,” he “tore around the patch” (his words) for more than 1,500 hours, and he spent more than 10,000 hours “tinkering,” completing five full RV projects, owning and maintaining more than 11 airplanes of various shapes, speeds, and sizes. An obsession that lasted more than 70 years allowed him to find and fulfil his passion. He was his happiest thinking about and working on radio-controlled and real aircraft, aircraft history and nostalgia, rebuilds and new Van’s RV projects, and he found many great friendships along the way.

My dad passed away in February of this year, and he will be dearly missed. My whole life was shaped by his interest in aviation and aircraft, as I’m now a commercial airline pilot with more than 10,000 hours, a credit to his influence on me. It’s a comfort knowing my father’s incredible, lifelong passion lives on in me, as well as the countless builders, students, pilots, and friends he impacted along the way.