By Lisa Turner, EAA Lifetime 509911

This piece originally ran in Lisa’s Airworthy column in the May 2025 issue of EAA Sport Aviation magazine.

Even with spring around the corner, it was cold and drafty in the hangar. I pulled the collar up on my jacket and shivered.

“I should have put my other coat on. It’s freezing,” I said to Rick.

“Sorry, I don’t have any heat in here. I was hoping the day would be a little warmer.”

“That’s okay. Are you going flying?” Rick had the cowling off on his Sportsman.

“I thought I was, but I have some work to do here. Let me ask you this. How bad is it to not put an aircraft into storage for the winter?”

I paused, looking at the airplane. The tires were almost flat, cobwebs stretched from the trailing edges of the wing to the strut, and a layer of gray-yellow dust sat on surfaces.

“Not good. Just looking at the outside, I’m guessing you didn’t do anything, including draining gas from the tanks or charging the battery.”

“You’re right. But it’s only been four months sitting.”

“Awful bad, then, is the answer.”

* * *

Last year I noticed a few homeowner magazines that responded to readers’ questions about how good or how bad a particular action would be. For example, “How bad is it to not change your home air filters every three months?” The author would classify how bad it was: very bad, not so bad, and not bad at all. However simplistic, I liked the idea and thought we could easily apply it to aircraft maintenance. What I enjoy about it is that it doesn’t pigeonhole everything in good or bad; there’s a continuum.

I’ve thought about many of the aircraft maintenance situations I’ve encountered along with the questions. I’ll categorize some of the top maintenance missteps on a “how bad” scale and why. I don’t want to step on toes, so I will use my own classification system.

How awful is it? I’ll use pretty awful, somewhat awful, and not awful. You can tell I’m having a bit of fun here, but the answers are serious. Please understand that these are my own opinions on the circumstances. There’s always some wiggle room for exact situations you might find yourself in.

Back to the beginning. How awful is it to not store your airplane per the manufacturer’s recommendations and with a checklist? I said pretty awful, and here’s why.

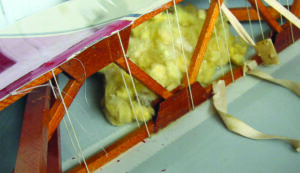

Aircraft that are not stored with some protection against moisture will age faster. Airplanes stored outside will suffer the most, but even inside storage will take its toll. An added problem inside is that small creatures, such as mice and insects, are also trying to stay dry and warm. Your airplane may be an ideal place to set up. If you have a fabric-covered aircraft, you may already know that mice love the lacing cord we use for the attachments. It makes perfect nesting material.

Batteries will suffer over an extended period without attention, as will rubber compounds in the tires, upholstery in the seats, and a variety of other materials in our airplanes.

If your engine is using automotive gasoline, you know auto gas degrades over time. Depending on the grade of gasoline and whether it has ethanol in it, it can turn to varnish and sludge in a surprisingly short time. If you have a Rotax engine, you’ll want to either drain the autogas or store it with aviation fuel. This is a vulnerable area where your engine manufacturer knows best.

What to do? We usually fall into the inactivity trap inadvertently. If this is the case, do the research on how best to prepare your airplane for a return to flight. If you are deliberately putting your aircraft into storage, follow the checklist your manufacturer recommends.

Need more information on what to do if you unintentionally left your aircraft idle for months? See “Ready to Fly?” EAA Sport Aviation, May 2023.

Skipping the Preflight

Pretty Awful.

Why? All it takes is one thing, like forgetting the chocks or a gust lock. You already know this. But there’s more to this issue. You know that if you do your thorough preflight, go flying and return, and then fly again soon after, it’s not likely that something has changed in the interim. Or has it?

At the airport we see this all the time. A pilot returns for a passenger, returns for a rest break, or returns for another reason and then jumps in the airplane and leaves again. This is an area where good judgment is critical. Things can — and do — go wrong in these short breaks. How much of an inspection is required under these circumstances? This depends on your own comfort level, situational awareness, knowledge, and experience.

I recommend a short “already been flying” checklist for these situations, especially if you have fueled the airplane in the interlude. Yes, it will take another five minutes, but it will also help you tune into anything unusual. Look at your regular checklist and think about what should go on the short one. Laminate it and put it with your other lists. Don’t skip it.

Not Waiting for the Oil to Reach Temperature Before Leaving the Ramp

Not awful.

What does your engine manufacturer say? This will vary depending on what you are flying. In most cases, they will want the engine to be up to temperature before your takeoff. Whether you do this before leaving the ramp or while you gently taxi to the run-up area will depend on recommended procedures.

Follow the exact procedures for starting and warmup as dictated by the engine manufacturer. It is likely to be specific.

Short Engine Runs to Warm the Oil When You Can’t Fly

Pretty Awful.

I still see this topic debated. We already know that if you have a car, truck, or tractor that has sat for a while, it’s a good idea to start it and warm it up for a bit. But is it? Don’t confuse a short “warmup” with an extended run. For the vehicle, we should be getting it moving and running it long enough and with enough stress to get condensation boiled off the internal surfaces. The same goes for our aircraft.

Short ground runs are never recommended for your airplane. These short runs will not burn off all the moisture. This drives corrosion and shortens the life of your engine. I’ve included a short piece of advice from Lycoming that you can find in the online resources called “Frequency of Flight and its Effect on the Engine.”

Theoretically, a long ground run where you get the temps all the way up is okay. But “in theory” isn’t real world, and Lycoming says, “Prolonged ground running in an attempt to bring oil temperature up is not recommended because of inadequate cooling that may result in hot spots in the cylinders, [and cause a] baked and deteriorated ignition harness and brittle oil seals which cause oil leaks.”

If you cannot go flying, I don’t recommend short or long ground runs. However, always defer to the manufacturer’s advice.

Not Checking and Cleaning the Oil Sump Screen if You Have One When You Change the Oil and Filter

Somewhat awful.

We’re putting the cart before the horse when we say oil screen. In an informal poll of aircraft owners, only 30 percent of them say they clean this screen. But when I asked how many owners cut open their oil filter for inspection, 80 percent said yes. When I asked how many owners sent the oil out to a lab periodically (Aviation Laboratories or Blackstone Laboratories) 60 percent said yes.

If you are doing your own oil changes, never skip cutting the filter open (with the right tool) and performing an inspection on the pleats. If you’ve already been doing this for a while, you know that trend analysis and experience over time is the key to monitoring engine health.

Oil analysis on a regular schedule is also a good idea. I’d check with the manufacturer of your engine, and also with the owners group to determine what that schedule should be.

Back to the oil screen. Yes, you should inspect the screen carefully for anything unusual. This is a coarse screen and, of course, does not take the place of your oil filter. If you’ve looked at it and it’s free of extraneous material, I wouldn’t worry too much about it. I personally will take the time to clean it and also feel for grit. Over time, you’ll know a lot about how clean everything is or not.

A corollary to the filter pleat inspection is to never punch a hole into the old filter to help drain the oil. Not only will this obviate doing an internal pleat inspection because of contamination, it will actually make a bigger mess that spreads to everything in the vicinity. Engine oil has an odd way of attaching itself to everything you don’t want it on.

Choosing the Fastest Mechanic to Do Your Annual (or Condition) Inspection

Could be awful.

What’s wrong with fast? Nothing. But if “fast” means “skip,” it could be a problem. When I first began doing annual and condition inspections, owners would get upset with me because I’d find things that their previous mechanic didn’t find. I was naïve and just figured I was slow and picky. It turns out that you want slow (thorough) and picky on your inspections. Hearing “my last mechanic didn’t flag that” is a sign that the inspection might not be as thorough as it should have been.

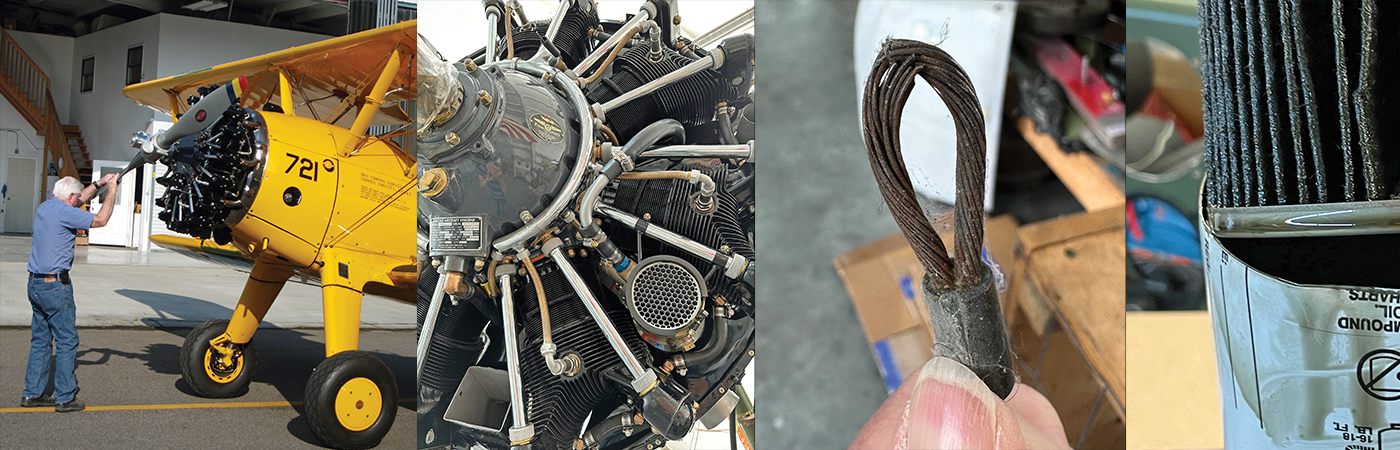

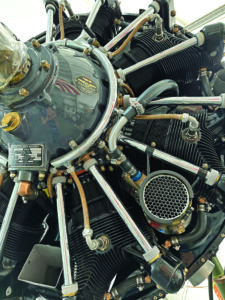

Not Checking for Hydraulic Lock When You Fly With a Radial Engine

Pretty awful.

Any time a radial engine is shut down for a length of time, oil can drain into the lower cylinders. Since oil is incompressible, as the piston approaches top dead center and both valves close, the oil can physically stop the piston. If forced, a little or a lot of damage can occur. This can manifest itself as a loosened cylinder, a bent rod, or loose spark plug inserts.

Prevent this from happening by following the exact start procedures for the engine. Typically, this involves turning the prop through by hand (ignition off) to feel for a lock so you can clear it. This requires attention and experience. Some pilots with lots of experience can bump the starter from the cockpit and feel for hydraulic lock. The remedy if you find a lock? Pull the spark plug(s) and drain the offending cylinder(s).

Inverted engines, such as the de Havilland Gipsy Major (a four-cylinder, air-cooled, inline engine) are also susceptible to hydraulic lock for the same reason.

There’s a lot to be thinking about as we provide the best care we can for our airframes and engines. One of the best things you can do to not miss anything and bypass poor practices is to keep your maintenance manuals, pilot’s operating handbook, and checklists organized and up to date, and be familiar with manufacturer recommendations and cautions.

Whether your airplane is experimental or certified, pay particular attention to service bulletins, factory letters, and ADs. Keep refining your checklists. Get other expert eyes on your work and engage with your owners group or club. These tactics should keep the “awfuls” away, delivering safe and worry-free flight.

Lisa Turner, EAA Lifetime 509911/Vintage 724296, is a retired avionics manufacturing engineer, an EAA technical counselor/flight advisor, and A&P mechanic. Lisa has authored six books. Dream Take Flight details her Pulsar building and flying adventures. For the Love of an Airplane is the biography of Jerry Stadtmiller, a man who restored more than 100 antique aircraft to flying condition. Learn more at DreamTakeFlight.com. Write Lisa at Lisa@DreamTakeFlight.com.