By Jeffrey Orear, EAA 529128

This piece originally ran in the May 2025 issue of EAA Sport Aviation magazine.

I became interested in building a Hatz biplane after seeing Chuck Brownlow’s (EAA 323477) Bronze Lindy winning Classic many years ago. I’ve always had a soft spot for biplanes, and the Classic really caught my eye. With its rounded fuselage and corrugated aluminum ailerons, it is the spitting image of a Waco’s little brother. At the time, I had recently finished building a Van’s RV-6A and was suffering from a bit of the “empty nest” syndrome. I wanted a project that would challenge me, and building an airplane from plans fit the bill.

I ordered my plans from Makelan Corp., which now are available from the Hatz Biplane Association, and got to work. In keeping with the desire to challenge myself, I struck out building with the intent of doing as much of the construction as I could.

I decided to begin construction with the wings, which are built from wood. Being a longtime RC model builder, the wings for the Classic looked strikingly similar to that of several of the giant-scale airplanes I had built in the past. Since I had my RV to fly, I wasn’t pressed to proceed with construction at a rapid pace. Wisconsin winters can be long and cold, so the upper wing center section was built during the first winter, with each of the four wing panels being built in subsequent winters.

Next was the welded tube fuselage. I had never welded before, but in keeping with wanting to do everything myself, I set out to learn. Fortunately I had an excellent mentor in Don Stewart, EAA 4515, who is the designer of the Headwind, Foo Fighter, and 265. Don steered me straight with gas welding, which I was able to parlay into TIG welding. Once I realized a pair of old magnification loupes I used in my dental practice fit under my welding hood, I became comfortable welding things up.

As I mentioned, to me the Classic looks like a miniaturized Waco, and a Waco has a round engine. At the insistence of my RC friends, and a core belief that biplanes need round engines, I decided to install a Rotec R3600 radial. The choice was made simple at the time, as the Verner nine-cylinder had not been introduced. Builders now have two radials that fit the bill perfectly for the Classic. Because I was no longer using the flat-four Lycoming O-320 the Classic was designed for, I needed to fabricate a boot cowl for the Rotec, as I was not considering a full cowl. Since I didn’t have the equipment, talent, and experience to build a boot cowl from aluminum, I decided to use fiberglass.

I wanted the boot cowl to butt up against the forward fuselage skins and not overlap, so that necessitated making a mold. I had no experience with that, so off to YouTube I went, learned the process, and dove in. The mold was made from polyester resin and mat fiberglass with a sprayed-on coat of gelcoat over a Styrofoam and plywood plug.

Once I got the boot cowl done and mounted, I stepped back to have a look. A little voice started saying that engine and boot cowl would look great with a speed ring! To be honest, I was a bit burnt out making a mold and then laying up the boot cowl, so the speed ring was done as a direct layup over a plug.

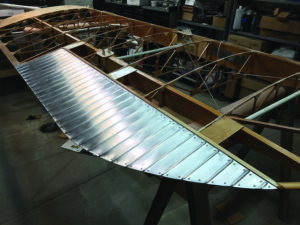

Having built an RV, I had previous experience with aluminum, which was helpful in fabricating various parts for the Hatz, including the windscreen frames and ailerons. Fortunately for me, my fellow Classic builder, friend, and Gold Lindy winner Rick Shultz, EAA 510121, (See the feature story in our March issue. –— Ed.) lent me his press he made for making the corrugated skins required for the ailerons. They really put a finishing touch in the Waco look-alike quest.

The last challenge involved painting, which has never been my strong point. After much research, purchase of an HVLP gun and turbine, and several practice sessions, I set up a poor man’s spray booth using a tent-style carport and started in. I wanted to have a vintage look to the airplane, so I wasn’t going for a super glossy look. Poly Fiber’s Poly-Tone gave me a more weave-showing appearance to the fabric and was extremely easy to shoot.

I named the airplane Patience for a couple of reasons. First, it took a lot of patience to build over 13 years. The other reason was in honor of all my patients who entrusted me with their care over the 37 years I practiced dentistry. You might say without my patients, Patience would not have been possible. I was tempted to put “Patients” on the side of the airplane, but I was sure I would tire of people telling me I spelled “Patience” wrong.

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->