Vic Syracuse, EAA Lifetime 180848

This piece originally ran in Vic’s Checkpoints column in the July 2025 issue of EAA Sport Aviation magazine.

I often get asked during prebuy inspections which is the better choice: a carburetor or an injection system. Since it’s not a straightforward answer, with each having its own pros and cons, I thought I would share my opinions on each.

Both serve the same purpose — delivering fuel to the cylinders in a proper ratio for combustion to take place. The injection system does a better job at proper distribution, which I will highlight next month. Each system has its own operating idiosyncrasies from a pilot’s perspective. So, let’s start with the carburetor, since it was the first one to the scene.

The carburetor was invented by Karl Benz in 1885. He was also one of the founders of Mercedes-Benz. While carburetors have been almost completely replaced in the automotive industry by fuel-injection systems, they are still prevalent in the aircraft industry, including newer engines such as the Rotax series. Those of us in my age bracket who learned to fly in civilian life almost certainly learned to fly in a carburetor-equipped airplane, such as the Cessna 150 series, Piper Cherokee series, or Champs and other similar aircraft. Later, when transitioning to higher horsepower and complex aircraft, we learned about injection, suitably noting that the carb heat control was missing. For some, it took a while to forget about applying it during the prelanding checklist.

Without going through a lot of detail about the inner workings of a carburetor, suffice it to know that the carburetor is basically a single-point fuel-injection device. It “injects” the fuel at one point in the intake system of the engine. From there, it is distributed to all the cylinders. On single-cylinder engines, such as lawn mowers and other small gas-powered tools, it is still an efficient method of fuel distribution. But on engines with multiple cylinders, lots of factors get in the way of equalizing the distribution. First, there are the physical lengths of the intake tubes that are hard to make exactly equal just due to physical limitations. Usually there are connecting points for which gaskets and hoses are used, which are now possible points of leakage.

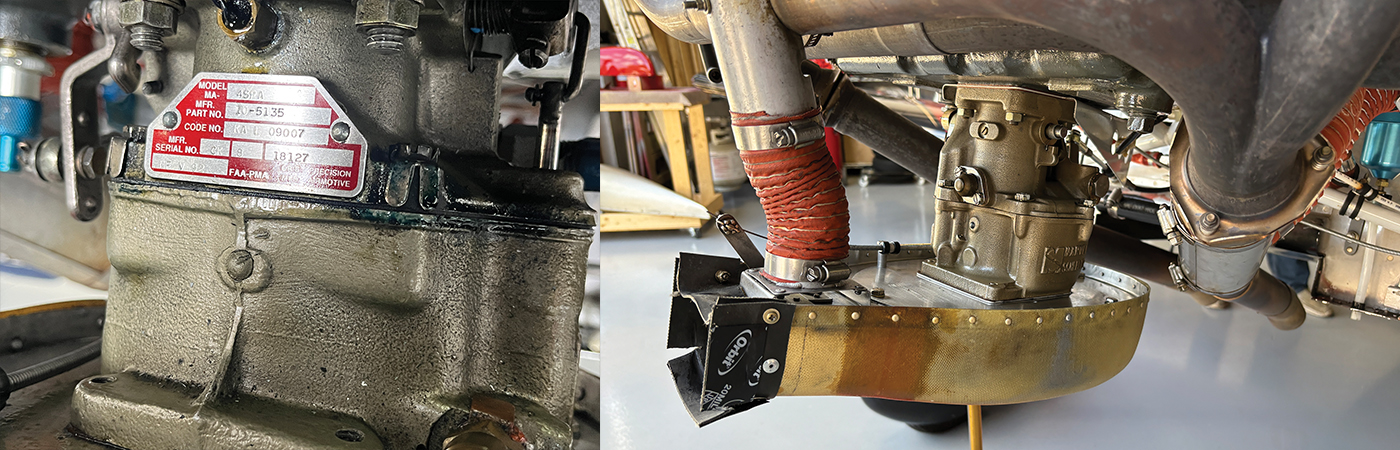

This “leakage” can create its own series of problems. In automobiles, the carburetor sits on top of the engine, and the fuel is sucked down into the engine. Gravity helps here, and for those of you who remember starting cars on cold winter days, usually a couple of pumps of the accelerator prior to engaging the starter made for quicker starts. On aircraft, the carburetor is usually installed on the bottom side of the engine, in what is called an “updraft” configuration. The fuel is pulled up into the cylinders by the suction of the cylinders during the intake stroke of a four-stroke engine. Now you can understand why leaks in the intake system can affect the fuel distribution and make for hard-starting engines.

The other problem is that pumping the throttle prior to engaging the starter does not get any fuel into the cylinders. The accelerator pump in the engine will squirt fuel straight up, and then gravity helps it fall right back down, usually into the airbox. This situation, coupled with a weak battery, is the most prevalent cause for intake fires during engine starts. So, a word of warning here: DO NOT PUMP the throttle on a carburetor-equipped engine unless the engine is cranking, and even then, only judiciously. Most certified aircraft have a primer system for cold starts that injects fuel directly into the primer ports of the cylinder(s). The primer ports should have the proper primer injection nozzle in them that atomizes the fuel as it is sprayed into the cylinders.

Once the engine is running, due to the physical limitations discussed, the fuel is not exactly equally distributed to all the cylinders. So, no matter how hard one tries, it is not possible to get the same amount of power from each cylinder, even with fancy porting and balancing.

Let’s go back to that carb heat control. The air flowing through a carburetor is channeled through a venturi, where the fuel is “injected” due to the low-pressure effect of the venturi. Let’s just call it magic for now. Once it gets past the low-pressure area of the venturi, the mixture of fuel and air now expands as it leaves the carburetor, and this rapid expansion also causes a temperature drop, by as much as 30-40 degrees, which can now lower the temperature to below freezing. Any moisture that was in the air entering the carburetor will now become ice and can stick to things like the throttle plate, which is at the exit of the carburetor.

This blockage has the potential to cause a serious power loss and is most prevalent at lower power settings, such as when landing, when the throttle plate is already mostly closed and easier to block. However, under certain atmospheric conditions, such as high humidity, it is possible to get carb icing under full-power conditions. In both cases, the symptoms are usually a rough-running engine. Unless corrective action is taken quickly, it can lead to a complete power loss.

So, the cure is a function called carburetor heat, which helps raise the temperature back to above freezing and melts the ice. The source for this heat is usually a shield wrapped around the exhaust pipe, much like a heat muff. The key here, and this is important, is that the carb heat is most effective when the exhaust is hot, so that is why it is on the landing checklist and is applied prior to reducing power. At low power settings there may not be enough heat or time available to melt the accumulated ice.

There is one other big gotcha here that has been the demise of many pilots and their aircraft. If ice has already accumulated and there is a noticeable power loss, activating the carb heat will initially cause even more of a power loss. From the accident database, too many pilots have learned this the hard way, with their immediate reaction being to remove the carb heat, which usually causes a complete power failure. The reason for the power loss upon application of the carb heat is that the ice melts and now water is added to the fuel mixture. The water does not burn as well as fuel, so there is a reduction in power, which will usually clear up within 30 seconds if the carb heat is left on. Sometimes, since the heated air is now richer, the mixture may need to be leaned to facilitate a smoother-running engine.

Pilots who transitioned from Cessnas to Pipers noticed that the carb heat was not part of the landing checklist and only checked during the pretakeoff checklist for proper operations (watching for a small rpm drop due to the richer mixture). Why the difference? Well, Cessnas were powered by Continental engines, and the intake system did not go through the oil tank, thereby allowing the intake pipes to run cooler and be more susceptible to freezing. The Pipers were powered by Lycoming engines. The carburetor was attached directly to the oil sump, and the intakes went through the oil sump as well, which kept them surrounded by warm/hot oil. The Lycoming engines were not as susceptible to carburetor icing, and carb heat was only applied if icing was suspected.

By now you probably think the carburetors are little demons. Not really. They’ve been around for a long time for lots of reasons. They are cheaper, easier to install, and usually easier to start on both hot and cold engines. They do not work well for any aerobatics that might include zero to negative g’s, but that is not a limiting factor for most sport pilots. They are also reliable, with only a few airworthiness directives over the years pertaining to unsecured jets and sinking floats.

Next month I will go into details on injection systems. In the meantime, for those of you with carbureted engines, just know that a carbureted airplane is capable of keeping the fun factor alive!

Vic Syracuse, EAA Lifetime 180848, is a commercial pilot, A&P/IA mechanic, designated airworthiness representative, and EAA flight advisor and technical counselor. He has built 11 aircraft and has logged more than 11,000 hours in 75 different types. Vic founded Base Leg Aviation, has authored books on maintenance and prebuy inspections, and posts videos weekly on his YouTube channel. He also volunteers as a Young Eagles pilot.