By Malcolm Brubaker, EAA Lifetime 428307

This piece originally ran in the July 2025 issue of EAA Sport Aviation magazine.

Stabilized Dacron is the easiest, fastest, and least expensive aircraft fabric to install. That’s why it’s the perfect choice for ultralights and older light-sport airplanes. Unfortunately, there is not a lot of literature or videos available about installing it, and most manufacturers of these kits and their sail makers are no longer in business.

This is a general guide with tips to install and care for Dacron sails. It is, hopefully, the first article in a series I would like to call “Evaluating and Rebuilding a Barn Find.” I invite others to consider this endeavor and submit similar articles or stories on the topic of maintaining the aging fleet of ultralights.

This is by no means a comprehensive guide, However, I am certain plenty of people who have cracked open a box of sails will find some handy tips within this article.

- Read the owner’s manual. Before getting started, do your research. Find a copy of the owner’s manual for your specific airframe. Each manufacturer has specific installation instructions. These manuals are essential for the proper assembly and installation and should be studied before getting started.

- Preparation is key. A clean work surface is an absolute must. If you want to keep your new sails looking great, try to keep the frame, fabric, work area, and your hands as clean as possible. Sometimes, when people send a piece back for adjustment, I’m surprised at how dirty the fabric can be.

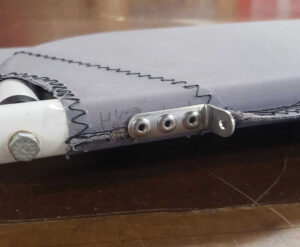

You’ll want to make sure any rough or sharp edges are filed down so it does not catch the fabric. This is also a great opportunity to take a close inspection of your frame for damaged, worn, or corroded hardware. If the fabric is to last 10 years, so should the plastic and hardware.

You should also get all the necessary tools ready. Strong cords, pliers, a hot knife, a soldering gun with knife tips, and a rivet gun — anything the manual calls for. Small areas, like the ailerons and tail section pieces, are typically a one-person job. Larger areas, like the wings, may require an extra set of hands.

- Start the installation. On some designs, such as the Lockwood Drifter or the CGS Hawk, you will slide the completed control surface into the sail envelope as far as it will go. Rubber gloves will help to get a better grip on the fabric. If you think you need to grab the fabric with pliers, you could use a piece of neoprene from a can koozie to grip and protect the fabric from the pliers.

Pulling, sliding, tapping, ramming, and twisting are all part of the process! If you find you are having a lot of trouble, contact the kit manufacturer, the type community of your aircraft, or your sail maker for advice. This is not rocket science. These ultralights became popular because the average person is supposed to be able to build one at home!

In some cases, you’ll complete the frame assembly inside the control surface fabric, like Phantoms and T-Birds. Pulling it on, the first part will be fairly easy, but the final attachment can be difficult as the sail is being tightened at the same time. This will take some force and torque. Each manufacturer has ways of doing this as explained in the manual. One way is the use of a jig, which can be as simple as a cord wrapped around the tube and tightened by wrapping the cord around a screwdriver until the bolt holes line up. Do this gradually. You want to stop when the bolt holes are aligned. Overpulling will stretch the fabric or even break stitches.

- Secure the sails. Once the sails are on, you’ll want to tighten them and remove wrinkles. The final securing can be done in several ways and largely depends on the type of airframe and how the sails are designed. Manufacturers have developed multiple ways to obtain the tightest fit possible, such as shims, mechanical tensioners, snaps, Velcro, or zippers. Whatever method used for your airframe, the manual will spell out the best way to go about it.

The CGS Hawk and Lockwood Drifter call for contact cement or two-sided tape to hold the envelope tight. If the sail is a little loose after installation, you can place some shims between the fabric and the tubes. A common practice on the Aventura, CGS Hawk, and Buccaneer is to wrap the leading-edge tube with insulating foam.

On most wings, you insert battens into the rib pockets to give the wing its shape. Always make sure the tip of the rib stays in the center of the rib pocket. You may need a second person to keep the rib centered as you force it into place.

Lacing is another technique to finish the tightening process used by RANS, BushCat, and Skyranger. Some designs will cover the lacing with Velcro flaps. Zip ties are an option and part of some designs, but they need to be properly installed and tightened before the sails are permanently secured.

Other airframes, like the Aerolite 103, are designed to complete the frame assembly before stretching the sails over. These use zippers on all control surfaces, the same way the Quicksilver uses zippers on its ailerons.

I receive several calls a year asking how to shrink or remove wrinkles in stabilized Dacron. Do not iron woven Dacron or any other sail material. There is no way to evenly heat the fibers as the manufacturers do. You’ll ultimately end up with wavy and puckered fabric, or even a burned-through hole.

Everything expands and contracts depending on the temperature and humidity, so your sails may look slightly different on a cold, humid morning compared to a hot, dry afternoon.

- Place your hardware. Once the sails are installed, you can start finding where you need to place hardware, like hinges and cable fasteners, or add inspection plates. As a sail maker, I put patches and grommets where indicated, but I don’t cut the cable exits or attachment points. Use a solder gun to cut and seal the fabric as needed.

Inspection plates can be added anytime, anywhere you want to put one. A popular place to add inspection plates is around wing tank fittings. The covers can be left as is or painted. You’ll need two rings per cover. You’ll prep the rings by indexing them and drilling holes, and then attach the ring to the surface with two-sided tape. Next cut out the fabric on the inside of the ring, place the second ring inside the fabric, and then glue and rivet the rings together.

It will take time to install your sails, but the time and patience taken will determine the end result. A good-looking airplane will be worth it!

Now you have a beautiful aircraft with great sails. I’ve seen sails last from 400 to 800 flight hours. Some sails I’ve seen are nearly 20 years old and in great condition. Let’s talk about maintaining them to keep them looking vibrant and in airworthy condition for as long as possible.

- Clean the fabric. Before applying anything like a clear coat or decals to the fabric, make sure to remove any oil, dust, and dirt. You may need to use several types of cleaning liquids to remove dirt and stains. MEK, acetone, mineral spirits, and Simple Green type cleaners are all safe to use on Dacron fabric. Remember to follow up with dish soap after using cleaners and then rinse with water. Never use chlorine bleach, but oxygenated bleach is safe to use.

Personally, I would never use a power washer to wash sails I still intended to fly with. If pressure from a regular hose and cleaner is not enough to remove a stain, you may need to live with it or replace the sail.

- Apply a clear coat. Clear coating is one of the primary ways to keep your sails looking their best. While it can be applied months or even years after the sails have been installed, it’s best to do so before any dirt or oil is embedded in the fibers.

Aero-Thane is the most common clear coat for aviation applications, but some people use automotive clear coats. Clear coating should not be used on sails that are meant to be removed or folded for storage as it makes the sails permanent on the frames until they are ready to be replaced.

- Protect from the sun. There are several silicone-based UV protectants designed for fabric. 303 Aerospace Protectant is a UV protectant originally developed for aviation use. Protectants can be reapplied a couple of times a year. Consider these protectants like sunscreen. The longer the sails are out in the sun, the more often it should be applied. However, silicone-based protectants make it almost impossible for decals or adhesives to stick to fabric unless you clean the fabric extremely well. A simple test: If duct tape sticks, so will a decal.

- Decide when to repair or replace. Sails need to be replaced when damage or wear is too extensive for reasonable repairs, or when they’ve deteriorated due to age and sun exposure. You should punch test your sails often, especially if they spend a lot of time outside. When you begin to notice things like a split in the rib pocket or color fading, a careful inspection is needed to determine if replacement is necessary.

Some issues are less significant and can be repaired, and prompt attention will keep them from becoming big issues. Small areas of torn threads can be secured with super glue. If a zipper fails, you can close the opening with zip ties every few inches, then cover it with clear tape (3M book binding tape works great). You’ll need to change the tape when it loosens. To clean or lubricate a stuck zipper, use a toothbrush and silicone spray.

To repair small holes, a patch and glue or tape can be used. My glue of choice is E6000. Take your time to make it look pretty. I’ve had patches that last well over a decade. Any patch, taped or glued, should be at least an inch and a half larger than the hole. When using adhesive to patch sails, or adhesive anywhere else in the process, be extra careful when using cleaning chemicals that remove adhesives.

It’s important to consider that after installation or repairs, that next flight is a test flight. Treat it as such! Your sails are a big part of what keeps your aircraft flying. They require maintenance and sometimes replacement, but it’s worth it to the loved ones you leave on the ground and the fun you’ll have in the sky.

Malcolm Brubaker, EAA Lifetime 428307 and the owner and sailmaker at Great Sails, is a self-taught ultralight pilot and former BFI (basic flight instructor). He’s a grandfathered sport pilot with a seaplane rating; Rainbow Aviation FAA-certified light sport repairman with a maintenance rating for aircraft, weight-shift control aircraft, and powered parachutes; and a 30-year volunteer at both of the largest air shows in America.