By Lisa Turner, EAA Lifetime 509911/Vintage 724296

This piece originally ran in Lisa’s Airworthy column in the August 2025 issue of EAA Sport Aviation magazine.

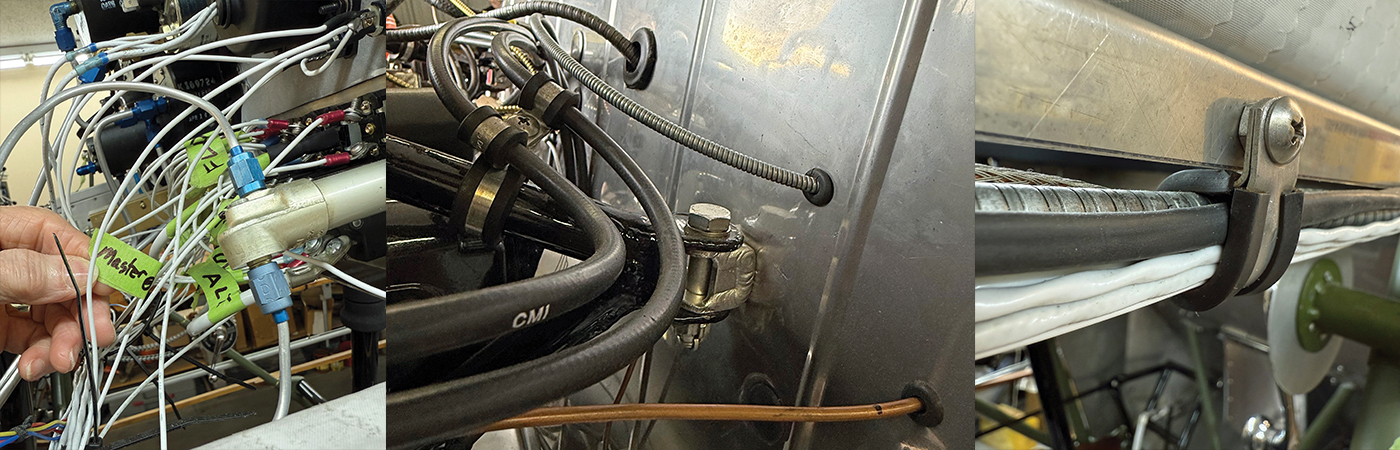

An observant EAA Sport Aviation reader noticed a photo I’d included in one of my articles, “Parts Left Over? The Inside Details” (April 2025), where the electrical bundle was routed and temporarily fastened with zip ties to the metal frame. He was concerned readers might think this was the way to attach the bundles. I assured him this was a temporary way to plan where the bundles would run during assembly.

This train of thought led me to my notes as a technical counselor. I reviewed all the times builders ended up with chafing or damage to wiring, air lines, hydraulic lines, and oil hoses. I’ve spent time rerouting and setting up systems with builders. It’s a perfect topic to help builders avoid the same mistakes I once made myself and repeatedly see in projects.

Much of the angst that comes from designing routings and figuring out how to secure the lines is because the plans we work from may not cover the topic fully, unless you are building a sophisticated and well-documented kit. Even then, not all the routings are exactly the same. All it takes is one change or the addition of a system — fuel, hydraulic, electrical/electronic, or air — to change where lines will go.

Here are the top errors I’ve seen and what to do about them in your current or future aviation project. This information is for homebuilts. If you’re restoring a certified aircraft, I’ll have additional tips later.

Rule No. 1 is to follow the exact instructions the kit manufacturer gave you, assuming you have those for routings and attachments. That said, it is uncommon to get this level of detail or instruction with most kits. The manufacturer assumes you’ll figure it out based on the systems you install. If you’re building a kit from plans, the routings and attachments will also be up to you.

Here’s my advice based on the problems I’ve seen over the years.

Unplanned Routings of Systems

On one project visit, a builder told me an electrical line was not testing active at the back of the panel. The panel was already populated with instrumentation, and the builder was testing each connection using a power supply.

“Where does this wire bundle exit?” I asked, pointing to a thick electrical harness disappearing under the seat.

“I’m not sure,” the builder said.

“Show me the schematic, and maybe we can figure it out,” I said.

“Schematic?”

“Yes, as in electrical routings and labels.”

“I don’t have one.”

“How do you know what goes where?”

“I don’t.”

We traced the faulty wire to a loose crimp on a connector and then mapped out the wiring for future troubleshooting and maintenance.

When you get to the stage of installing systems in your airplane, you will be tempted to skip drawing out where you are putting everything. This is one of those “pay me now or pay me later” situations. Would you rather add in the additional time now to plan and label everything, or wait until there’s a problem on the ramp that stops you from flying?

This documentation is a big maintenance and troubleshooting benefit. It can also add resale value to a future sale of the aircraft and help you on annuals and condition inspections.

Don’t be alarmed by my mention of a schematic. You don’t need a CAD program or even a computer unless you want to get fancy. Take a piece of paper and draw out what goes where. If you want to overlay this on something you already have from the manufacturer or from the plans, great. You may find you have to start over a few times as you identify the things you didn’t see at first, but that’s part of the fun, right?

Not Thinking About Heat

Many parts of the aircraft systems will enter the engine compartment. When you’re attaching and running these lines, you may not be thinking about the heat that’s generated inside a cowled engine when you’re flying. Be sure to use the nuts and bolts that are recommended, and use heat sleeves where necessary, especially around fuel lines.

In your first flight-testing hours, check and recheck engine bay and exhaust areas for chafing, binding, abrasion, and leaks. Pay extra attention to fuel lines. Operating the airplane can shift components, causing them to contact each other.

Using the Wrong Attachment Hardware

What are you using to attach your electrical harnesses to the inside of the airplane? You could use zip ties, lacing cord, clamps, standoffs, and bushings with a variety of techniques to protect the lines.

An A&P mechanic was doing a recent condition inspection on a 1992 high-time composite aircraft that had changed hands several times. He noticed that the builder had used plastic zip ties throughout the aircraft to secure electrical bundles to the airframe. When he looked into the engine compartment, he noticed one area where there was some discoloration and corrosion. He lifted the harness to look underneath. A large plastic zip tie had worked its way about 1/8 inch into one of the chromoly frame members on the engine mount.

He commented, “Amazing what a little chafing can do between materials.”

If you don’t have specific recommendations for what attachments to use in your instruction manual or plans, I recommend you pull out your copy of FAA Advisory Circular AC 43-13-1B, Acceptable Methods, Techniques, and Practices — Aircraft Inspection and Repair. This isn’t just a “paperweight,” it’s more a “desk-weight.” You’ll find entire sections on hardware and attachment protocol. You can find a link to it via EAA.org/Extras.

The other handy “desk-weight” is FAA-H-8083-30, Aviation Maintenance Technician Handbook. Granted, the first chapter is mathematics, but don’t let that stop you from looking at the rest of it. If you’re an A&P mechanic, you studied this material for your tests. It’s a go-to book along with AC 43-13.

Firewall — Not Using Grommets, Bushings, or Fittings

Besides the requirement to keep hot things away from materials that can burn in the engine compartment, we also need to keep heat and dangerous gases away from people inside the cockpit. This requires that we use the recommended material for the firewall itself, and that we seal anything that leaves the engine compartment and enters the cabin. This can be a lot of things — including fuel, exhaust gases, and electricity.

In one visit I made to a builder, the lines from the engine compartment went through holes in the steel firewall with silicone caulking loaded around them. The problem with this arrangement is that the silicone will quickly erode and fall out of the holes, leaving jagged gaps that will damage the line running through them.

Use grommets of the right size and material depending on what you are running. Bushings protect the line material, reduce damaging vibration to the lines, and seal the entry.

One of the deadliest mistakes is not protecting the cockpit from carbon monoxide gas. Humans can’t smell or see CO. In addition to a CO detector in the cockpit, make sure the ducting for cockpit heat is sealed and double-check through-firewall lines.

Forgetting Safeties

Since we’re talking about attachments, let’s not forget about safeties. When we attach something, we don’t want it to come off until we decide to take it off.

Look for holes in bolt heads and tabs that are empty. If you’re a beginner at safety wiring, get your local tech or A&P mechanic to show you the right way. Again, I refer to AC 43-13. It has the best instructions on how to safety wire anything. I remember the FAA A&P practical test I took long ago. One of the first things the examiner did was show me a large, elaborately safety wired engine bay as he snipped all the wires off while I looked on in horror, wishing I had a photographic memory.

Some folks think the torque seal we place on hardware is there to stop the piece from coming apart. It’s not. It’s there to help us with inspections, and it’s really excellent for that purpose. Don’t confuse torque seal with thread locker to safety hardware unless the manufacturer calls for thread locker specifically. If they do, it will be specified by name, color, and number.

Tips

Use plastic zip ties to temporarily run lines so you can determine what interference points you’ll have. Don’t forget to finish each area. It’s easy to overlook the ties when you’re getting it completed. Consider using colors. They will stand out, and you can use a different color for each system.

When you must break a line in the middle of a run, make sure the connections are crimped correctly, and secure the connection on both sides of the break. Otherwise, the stress and strain on the harness could cause one side of the connection to come loose. Note where these breaks are on your schematic so you can find them later if you have a problem.

When you’re placing conduit under seats and through the difficult-to-reach areas of the fuselage to run lines, always put in more than you think you’ll need. I put three extras in one aircraft and ended up using all three and wishing I had put in a fourth.

What does your condition inspection checklist look like? Make sure you include inspection items such as checking for chafing of materials, corrosion areas, integrity of through-firewall lines, and bushing, clamp, and grommet condition. Some of these items might even be good to put on your preflight checklist.

The key to using the correct attachments in certified aircraft is to write notes and take photos of what you are replacing. Most commonly, this will be when you perform repairs or restore an aircraft. On certified aircraft, we replace hardware with exactly what came off (and new) to meet the regulations. This is important because the specific nut, bolt, or screw was chosen for suitability and durability. The key is to make sure we’re using what the manufacturer specifies and installing it according to the instructions. Once again, you have the guidance of AC 43-13 as a reference.

To improve your knowledge of aircraft systems and how they go together, attend an EAA seminar, peruse the EAA bookstore, make it a topic of discussion in your next EAA chapter meeting, or spend time helping A&P mechanics in a maintenance facility.

Beware of the moments in your build when you really want to shortcut the painstaking detail. That’s what can make your flying more trouble-free. As much as you want to get in the air, stop when you’re feeling this way and take some deep breaths.

Like tying dozens of knots in fabric or sanding composites, you can be overwhelmed, feeling that your project is taking too long. This is actually the fun part of things. It’s the detail that will make everything work well together and save you time later.

Slow down and take the time to plan all your systems, including where and how they will be routed. Make up diagrams and schematics, label them, and make them part of your handbook. In that moment when you say, “What is that and where does it go?” you’ll be glad you have the answers.

Lisa Turner, EAA Lifetime 509911/Vintage 724296, is a retired avionics manufacturing engineer, an EAA technical counselor/flight advisor, and A&P mechanic. Lisa has authored six books. Dream Take Flight details her Pulsar building and flying adventures. For the Love of an Airplane is the biography of Jerry Stadtmiller, a man who restored more than 100 antique aircraft to flying condition. Learn more at DreamTakeFlight.com. Write Lisa at Lisa@DreamTakeFlight.com.