By Phillip Johnson, Chapters, EAA Canadian Council, Ottawa

In the early 1990s I started building a Cozy MK IV, and it was not long before I decided to use a Subaru EG33 230-hp engine for the powerplant. There were many naysayers that said it was fraught with issues, and it would not work. After a lot of investigation and speaking with the training department at Subaru Canada, I decided to go ahead, and they advised me that a very low milage SVX had been in a rollover accident and was written off by the insurance company. I found said engine, and it had only completed less than 5,000 km, so this engine had barely been broken in. The engine was at a wrecker’s yard not far from home, so I went to see the engine at the wrecker’s yard and agreed on a price and what would come with the engine, and they delivered all the parts in the following days.

After a complete strip down of all the ancillary components and a thorough cleanup from some road grime, I set out to find a propeller speed reduction unit (PSRU). I opted for the Ross Aero PSRU as that put the thrust line in line with the engine’s crankshaft and offered a gear ratio that met my needs for best performance, 1.85:1. This gave a max propeller speed of 2900 rpm when operating the engine at its red line of 5400 rpm. Since the max recommended Cozy propeller diameter was 72 inches, that gave me a tip speed of 620 mph and with a forward speed for 230 hp power source around 220 mph, the effective tip airspeed would be around 660 mph since the rotation and forward speeds are orthogonal. At 660 mph at sea level, that yielded 87% Mach, which was getting up there for noise and effects of compression, but with a slight reduction in prop diameter, it all looked great.

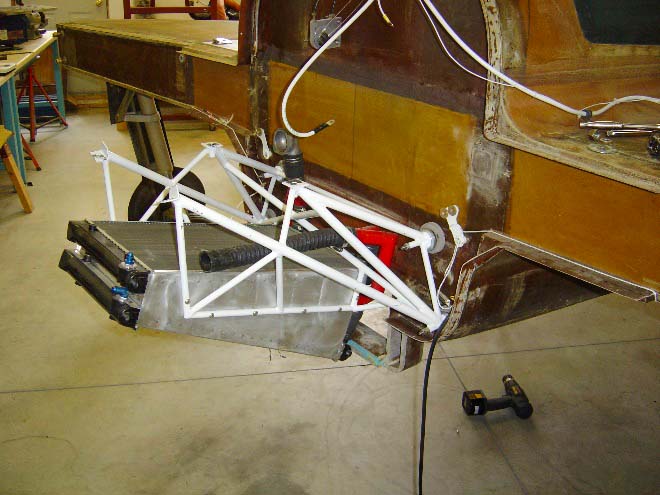

The next issue was cooling, and this was always the issue with automotive engines as they are mostly liquid cooled. I believe most automotive failures arise from excessive engine temperatures and significant temperature differences across the engine block/cylinder head. I decided to go with two very large VW Passat crossflow radiators configured in a vee arrangement, mounting under the engine with the opening of the vee being forward.

Remember, this is a canard pusher, so the air inlet is at the rear and under the fuselage using a large NACA duct. I increased the vertical dimension of the NACA duct and changed the sidewalls of the duct to accommodate the increased aperture. The NACA was no longer a flush mount, but I had seen some successful intakes done this way on other aircraft.

Most installations use the automotive thermostat to maintain the correct temperature of 90°C, and this is where I believe the issue lies. The Subaru locates the thermostat at the cooling input to the engine and controls the flow to appropriately achieve the best operating temperature. I thought I understood how the thermostatic system worked just like most people. You are flying along fat, dumb, and happy on a nice summer’s day, the engine is developing a lot of power, and coolant is passing through the engine and radiator pretty much unrestricted. The thermostat is wide open, and everything is just great, but now you go flying on a cold Canadian winter’s day. The thermodynamic efficiency of the radiator is magical and the coolant exiting the radiator is really cold, so now the coolant entering the thermostat housing causes the thermostat to close to maintain that design 90°C thereby reducing the flow through the engine. Since the engine is producing the same power/heat as on that hot summer day, and the entry temperature is maintained at 90°C, the slow coolant speed through the engine causes the exit coolant temperature to rise significantly, but the coolant speed through the radiator is also slowed so the radiator becomes even more efficient, and everything goes to hell in a handbasket. This is where the radiator bypass hose comes into play. As the thermostat closes, it slows the coolant through the radiator but not the bypass. The hot coolant exiting the engine is encouraged to flow through this short circuit and mix with some of that very cold radiator coolant to achieve the desired 90°C at the exit of the thermostat housing. The problem is that the sizing of the hose is set for automotive use and cannot handle the flow rate for consistent high power. The ideal would be a mixer valve with a large bypass hose, but that is another story. Since there is now a low coolant flow rate through the engine, and under high power conditions, the temperature difference across the engine can become excessive resulting in distortion of the block and cylinder heads. Notice how Subarus have a propensity for cylinder head gasket issues. To overcome this issue, I chose to change my approach to temperature control. I chose to control the thermodynamic efficiency of the radiator and allow the coolant to pass through the engine unrestricted, i.e. I took out the thermostat and controlled the airflow through the radiator(s). In doing this the temperature difference between the coolant input and output was just two or three degrees under all conditions.

To achieve this design, I made the roof of my large NACA scoop adjustable using a jack screw arrangement. The jack screw is controlled either manually, from the cockpit, or automatically using an Arduino microcontroller measuring the engine coolant exit temperature and adjusting the position of the NACA roof to yield the desired 90°C temperature. While I still need an electric fan for ground cooling, the Arduino controls the temperature through all phases of the flight. Below about -15°C, my EFIS shows the NACA intake to be almost completely closed and the engine temperature starts to fall away from the 90°C regulated temperature. The coldest I’ve flown is -20°C and I did see the coolant temperature fall to around 65°C.

The goal of this concept was to achieve uniform temperature across the engine block/heads and to minimise cooling drag once in the cruise condition. My EFIS does show me the position of the NACA roof and, while it is usually close to wide open in the climb, I do see the NACA inlet close up in flight, often to around 50% when in cruise.