By Vic Syracuse, EAA Lifetime 180848

This piece originally ran in Vic’s Checkpoints column in the August 2025 issue of EAA Sport Aviation magazine.

I work with many owners and buyers who are adamant as to whether they want an airplane with a carburetor or an injection system. Sometimes it’s just a matter of misunderstanding, such as thinking they “must” have injection to do any kind of aerobatics. Other times, it is due to their dislike of one of the systems, which is usually based on a bad experience. The most common complaint I hear is that their injected airplane engine is always difficult to start, but their buddy’s airplane with the carburetor always starts on the first or second blade.

Truth be told, carburetors and injection systems do require different starting procedures, and injected aircraft engines can be notoriously difficult to start when hot unless you use the correct procedure.

For many years, I hated Saturday mornings for this reason. Many of our customers would be out flying the usual Saturday morning breakfast flight with their buddies. Then they couldn’t get the aircraft restarted, especially after they taxied over to the fuel pumps. Guess who got the call? Guess who talked them through the next successful attempt? I finally wrote a column on starting procedures for injected aircraft engines, and the Saturday morning calls stopped.

Remember when all the rage in the automotive industry was about multiport fuel injection? What a joy it became to start a car. No more pumping the accelerator on a cold winter’s day to get the carburetor to work properly. Just barely turn the ignition key and the engine purred. Of course, there were those of us back then who could tune the carb’d engine to start just as quickly, but that’s another story.

Unfortunately, there is a big difference between injection systems on aircraft engines and automobile engines. Automotive injection systems are computer controlled. There’s an electronic injector attached to each cylinder that always injects the correct amount of fuel into the cylinder at the proper time. No more, no less.

With aircraft injection systems, such as Bendix, AVStar, and Airflow Performance, there is fuel pressure to each cylinder all the time. The amount of fuel available is controlled by the throttle position, which is connected to the fuel servo. The fuel servo then adjusts the fuel flow by adjusting the pressure to the fuel distribution unit, commonly known as the spider, which usually sits on top of the engine. From there, it is equally distributed to the cylinders.

The only “aircraft” injection system that I know of that works like an automotive system is the one from SDS EFI & Ignition Products. Pilots with those systems have reported that their engines do in fact start as easily as a car. I won’t delve into the proper starting procedures here, as I wrote a Checkpoints series that was published in the August and September 2021 issues of EAA Sport Aviation.

Let’s discuss the pros of injection systems first, as I believe they outweigh the cons.

A properly configured injection system is usually good for a few more horsepower without any other modifications because the fuel is more efficiently delivered to each cylinder. Since each cylinder is not exactly created equal in volume, the next best thing is to balance the amount of fuel appropriately to each cylinder. This is done in-flight by slowly leaning the mixture at cruise power and making a note of where each cylinder reaches peak EGT (exhaust gas temperature). The goal is to get them to peak at the same time, usually within 0.1-0.2 gph of fuel flow.

Note that you are not watching for the same exhaust gas temperature across all cylinders, as they will each be different. Again, what is important is that they all peak close to each other.

You get some real benefits by balancing the cylinders. If you get them all to peak simultaneously, your overall fuel flow for the same power setting is usually less. Before the balancing, since some cylinders peak before others, you end up running a richer mixture to keep some of the cylinders from running too hot.

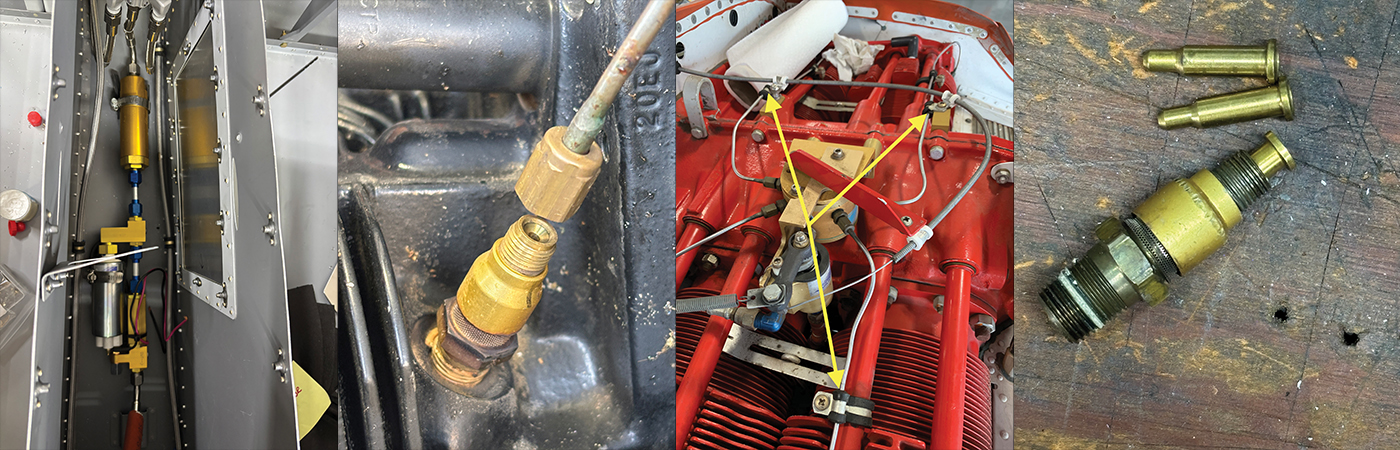

I usually see at least 1 gph less fuel flow after balancing, and sometimes even more. This is accomplished by changing out the inserts that go inside the nozzle body of the injector. Some of you may be doing this by using GAMI injectors. You will also notice that the engine is now much smoother at cruise because each cylinder is producing about the same amount of power.

Since an injection system is much more expensive than a carbureted system, usually by a factor of four, balancing the fuel flow will help pay for the system through decreased fuel costs.

Remember the carb heat function I discussed in last month’s column? Well, for injection systems there is no need for carb heat. The fuel is injected directly into each cylinder so there is no “icing” of the fuel. There is also no need for a gascolator, as injection systems will pass water, unlike a carburetor. Now, that is not to say you shouldn’t sump your tanks and drains, as the engine still needs fuel to run. It won’t run on water. Sometimes you can feel the system pass a slug of water as the engine will miss a beat. It will get your heart going for sure.

Instead of carb heat, there is a control labeled “Alternate Air.” This is only used if a blockage of the air inlet is suspected, such as during in-flight icing conditions caused by precipitation or if something is blocking the air inlet, such as a bird strike. Much like the symptoms of carburetor icing, inlet icing can usually be noticed by a drop in manifold pressure with a constant-speed propeller or by a loss of rpm with a fixed-pitch propeller.

Activating the alternate air will usually fix the problem immediately, unlike carb heat, which takes a while to melt the ice. In the case of alternate air, a different path for the inlet air is opened. Once the situation is resolved, deactivate the alternate air, as it is allowing unfiltered air into the engine. For this reason, its use should be minimized on the ground. Some alternate air controls need to be reset on the ground.

Both carburetors and injection systems have inlet fuel filters at the fuel servo for injected systems and at the carburetor for carb’d engines. The fuel in the injection system passes through a tiny hole in the injection nozzle/insert. These can get easily blocked by debris, causing a cylinder to run rough and even quit. You can quickly figure out this problem by looking at the EGT gauge if you have a multicylinder EGT gauge. The affected cylinder will have either a high EGT due to it running lean or an erratic EGT. Unfortunately, usually the only way to fix the blocked nozzle is to land, remove it, and clean it.

On a four-cylinder engine, a blocked injector can cause a rough-running engine. If possible, try to reduce power to lessen the vibrations and land as soon as possible. On a six-cylinder engine, it is usually not as noticeable, but landing should be the first order of business.

It’s best to pull the cowling off and let the engine cool down before trying to remove the injector to clean it. It’s hot, and the fuel in the lines is a fire hazard. Sometimes just blowing through the injector with compressed air or even your mouth will clear it. Other times cleaning it with a solvent such as Hoppe’s No. 9 is required.

On injected engines, it is a good practice to have a quality filter ahead of the electric fuel pump, capable of 75 microns filtration or better.

There is an AD for injected systems requiring the injector lines to be supported every 6 inches. For those of you who are installing your own injector lines, please do this properly, with Adel clamps. Amazingly, I have even seen them done with zip ties! At cruise power, the pressure in these lines can be over 25 psi. When/if the line breaks, it is basically a blow torch and can lead to a serious engine compartment fire. The only way to stop it is to completely turn the fuel off to the engine, which now means you are flying a glider. This can put a real damper on the fun factor.

So, what’s better — carb or injection? I don’t know that one is better than the other overall, except they each have their purpose. I think carbs are the lower cost option for lower-powered engines and mild sport-level aerobatics. But on serious aerobatic aircraft with higher horsepower, higher fuel consumption, and better high-altitude performance, the injection systems should be the first choice.

Vic Syracuse, EAA Lifetime 180848, is a commercial pilot, A&P/IA mechanic, designated airworthiness representative, and EAA flight advisor and technical counselor. He has built 11 aircraft and has logged more than 11,000 hours in 75 different types. Vic founded Base Leg Aviation, has authored books on maintenance and prebuy inspections, and posts videos weekly on his YouTube channel. He also volunteers as a Young Eagles pilot.