By Brian Garrett, EAA Lifetime 871500

This piece originally ran in the October 2025 issue of EAA Sport Aviation magazine.

In the depths of the COVID-19 pandemic, building an airplane just seemed like the right thing to do.

I’d been flying old certified airplanes for a while and was getting tired of the baggage that comes with that platform — outdated systems, constant maintenance, and little room for customization. So, I figured, why not build an airplane and at least be responsible for my own new problems?

I’d looked at the Sling TSi a few years earlier and was impressed. Back then, though, the idea of building one wasn’t on the table. But now? Sure, why not.

It took about 10 months from order placement to the kit’s arrival. When those five massive crates finally showed up, I cracked them open, ran through the inventory, and got to work.

I started my First Rivet YouTube channel to share the process — and to have a detailed record for future inspections. I’m a reasonably handy guy, and I’ve tackled plenty of large, complex projects before. This was just another one of those challenges: apply what I already know, and learn the rest along the way. One of the most rewarding parts of the channel has been connecting with others — answering questions, trading tips, and helping out fellow builders. I benefited from others doing the same, so paying it forward felt right.

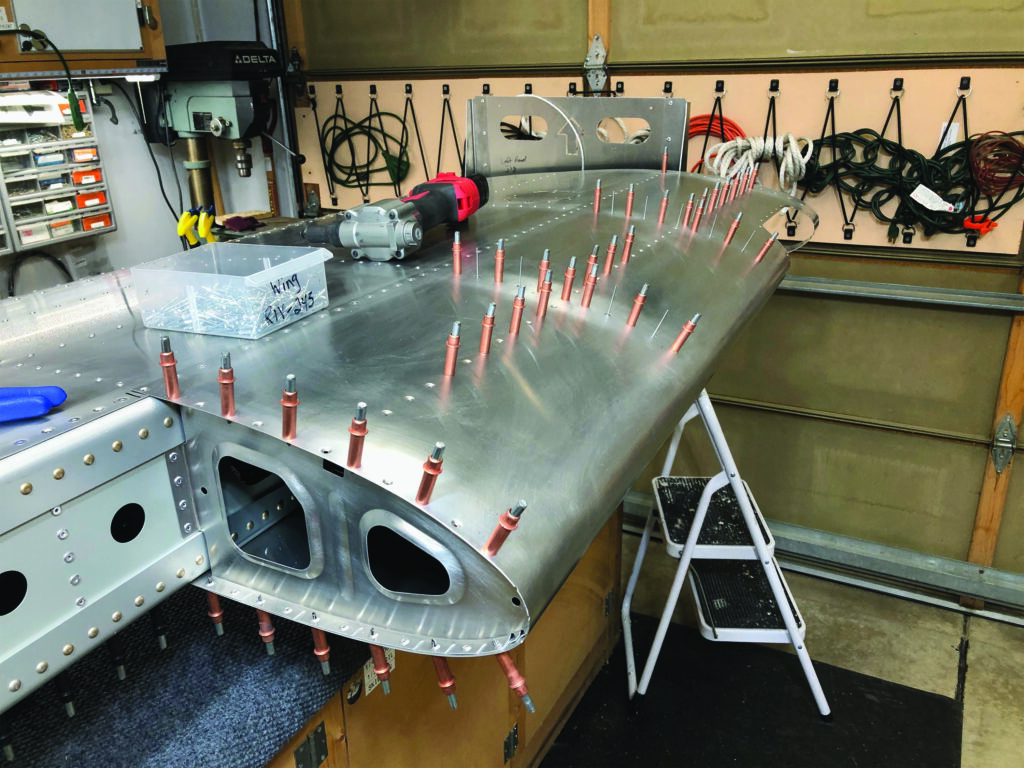

Like most Sling builds, I started with the empennage. Before kicking off, I did my homework — watched videos, read forums, and got in a few builder sessions for hands-on practice. One of the things I appreciated immediately about the Sling kit was the quality of the materials. Very little deburring was needed, and everything just fit. If something didn’t line up, it usually meant I had something backward or missed a step. Compared to what I’ve seen from other kits, the Sling design just doesn’t require as much fiddling.

I made a few upgrades along the way. I initially planned to replace the rubber fuel lines with aluminum, but ended up going with custom-made Teflon lines, which are more flexible, have a longer life, and are still a solid upgrade. I also swapped out the brakes for Beringer components. That meant some custom machining and a lot of double-checking to get the alignment right. Naturally, after I spent all that time on it, Sling added Beringers as an official option — no custom work required anymore. Typical, right?

Most of my upgrades were aimed at longevity and better performance — nothing too radical, but always with an eye toward improvement. I leaned heavily on conversations with vendors and builders who’d already gone down similar roads. And the truth is, you’re never really building alone. There’s an incredible community around experimental aviation, and someone’s always willing to lend a hand or share advice.

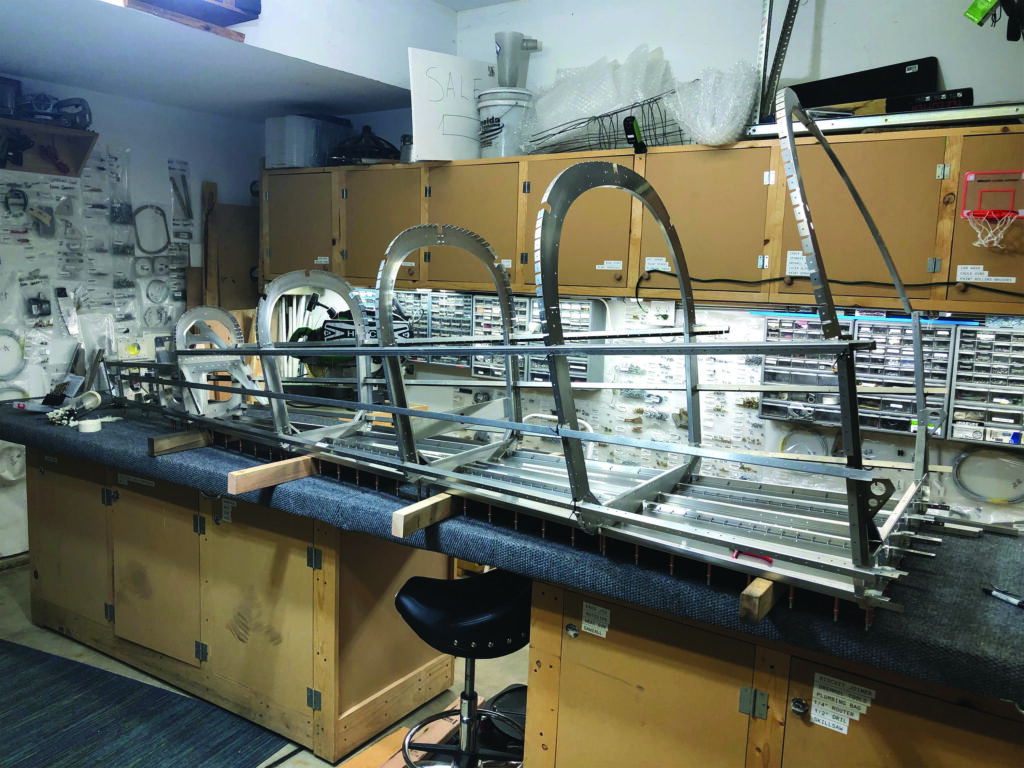

Now, when I say I built this airplane at home, I mean literally at home. The project was spread across my townhome, my neighbor’s garage (they had space for the wings and empennage), my in-laws’ garage down the alley, and even the snowbirds across the street who let us use their place while they were in Belize for the winter. From the start, I had to think through every phase — including how I’d eventually get this thing to the airport.

When moving day came, we used a 26-foot U-Haul with a wheelbase just barely narrower than the townhome garage door. I called in all the reinforcements — friends, neighbors, other pilots, even future Sling builders. We carefully rolled everything into the truck, made the short trip to the airport, and started the final assembly.

The closer you get to the end of a build, the more fine detail work it becomes. Installing the avionics was smooth thanks to great work from the shop I partnered with. Still, powering everything up for the first time — the classic “smoke test” — was nerve-wracking. I made it a point to invite people by the hangar and told them, “If you see something weird or out of place, say something.” When you’re that close to a project for so long, it’s easy to miss the obvious stuff.

One of the biggest milestones was the first engine run. Hearing it start and run clean was incredibly gratifying. After some taxi tests, paperwork, and the final airworthiness sign-off from the designated airworthiness representative, I took the first flight exactly three years after the kit arrived — on July 4, 2024.

Throughout the process, the experimental aviation community has been one of the absolute highlights. Whether it’s channel comments, DMs, or in-person meetups, everyone’s been willing to share their knowledge and support. That kind of camaraderie makes a huge difference, especially when you hit the inevitable speed bumps.

Honestly, one of my favorite nontechnical moments was the look on people’s faces when I’d tell them I was building an airplane. Most assumed I meant a model. “Nope — a real one.” Cue the wide eyes and the flood of questions: “How far can it go?” “How fast?” “How many people?” Watching the surprise and curiosity never got old.

Looking back, this project has been so much more than just building an airplane. It’s been a massive learning experience, a real challenge, and honestly, a ton of fun. I made plenty of mistakes. I figured out how to solve problems I didn’t even know existed. And I came away with a whole new level of respect for what it takes to turn a box of parts into something that can actually take flight. Of course, now I think everyone should build their own airplane.

That’s what my YouTube channel is really about — turning a dream into an aircraft, one rivet at a time.

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Readers consistently rate the “What Our Members are Building/Restoring” section of the magazine as one of their favorites, so don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->