By Mary Baker, EAA Lifetime 731258, EAA Chapter 846 (Wadsworth, OH)

Nobody knows how to make the most of every dime better than a nonprofit. When two nonprofits work together, the result can be not only cost-effective, but also professional. Looking for low-cost solutions to your chapter’s needs? You may want to turn to your local makerspace.

A makerspace can take many forms, but they all consist of a collection of tools available for use by their members. Think of your tool crib, except stocked with a laser engraver, 3D printer, button maker, a high-speed document scanner, and other high-tech tools.

For EAA Chapter 846 in Wadsworth, Ohio, the makerspace we use is at our local library. Stocked with the above machines and more, and staffed with helpful, knowledgeable librarians, our chapter has used their equipment for multiple projects. Other makerspaces may be membership organizations and charge a fee; at the library, the resources are free to use, and the only cost to the chapter is for materials.

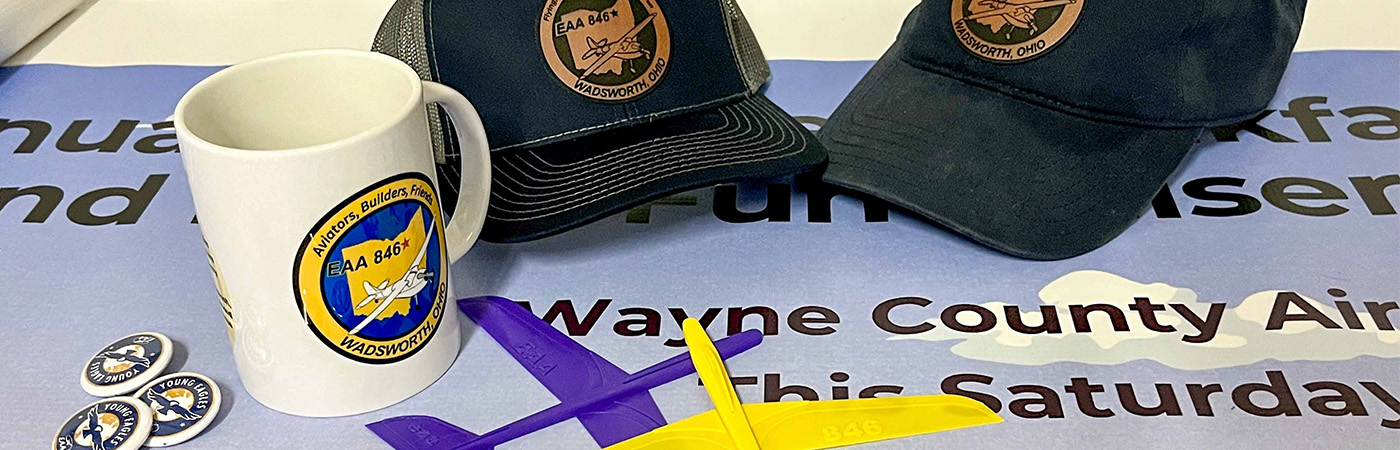

We’ve used their large-format printer to create large vinyl banners to promote our events and acknowledge sponsors. That same printer was used to print peel-off stickers for the chapter. Their button maker was used to make Young Eagles buttons for our 2025 Young Eagles events.

You probably already have some chapter members who have been dabbling with a 3D printer, making custom pieces for themselves. Our members kindly made gliders as giveaways at our Young Eagle events, but our makerspace has a 3D printer we could have used, too. Even easier is sublimation printing, used to create custom pieces using heat and specially printed designs. We have used this technique to create chapter mugs as thank-you gifts for speakers.

All these projects have cost the chapter less than $60 total, and the next project won’t cost us anything. We will be using the high-speed scanner to digitize old records and newsletters.

When using a makerspace, projects like these require a larger investment in time than money. A little creativity, a little time, willingness to be part of the process, and members interested in learning new things, can yield big results at an affordable cost for your chapter.

Additional Resources

- https://www.mcdl.info/makerspace – The makerspace referenced above at the Medina County District Library.

- https://makerspace.com – From Make magazine.

- https://makerspacedir.com – A directory of makerspaces.

- https://www.uc.edu/news/articles/2024/07/beginners-guide-to-using-amakerspace-2024.html – Beginners Guide to Using a Makerspace, University of Cincinnati.

- YouTube.com – Search for whatever makerspace topic interests you. You will find it.