By Scott Millhouse, EAA 583668

This piece originally ran in the January 2022 issue of EAA Sport Aviation magazine.

I’m a repeat offender when it comes to building homebuilt airplanes. I started a slow-build Van’s RV-9A in 2000 and finished it in 2007 equipped with steam gauges, a used O-320, and a constant-speed prop. I flew it about 550 hours including annual trips to SUN ’n FUN and Oshkosh. I had the itch to build another airplane and had an RV-7 about 75 percent complete when I was diagnosed with some heart blockage and had to have two stents in April 2014. The unfinished RV-7 was sold, and once I found out that BasicMed was still about three years out, I sold the -9A also to switch to light-sport aircraft (LSA). I purchased a flying RV-12 with a partner and started building an RV-12 of my own. One year later my partner bought me out, and about three months after that my new RV-12 was flying.

Unlike the -9A, I spared no expense since I thought the -12 was to be my forever airplane. It was fully equipped with all options including dual 10-inch SkyView displays. My new -12 went everywhere the -9A did but at a lower and slower pace with less fuel burn. Being an LSA, it is gross weight and baggage compartment limited and therefore was a solo airplane plus camping gear for my annual pilgrimages to SUN ’n FUN and Oshkosh. At AirVenture 2017 I found out from aeromedical specialists that I could now get a special issuance for my third-class medical. It took a few months and lots of tests and documentation, but I got my SI in November 2017. I immediately started searching for an RV quick-build project to buy. I got spoiled with the pulled rivet construction of the -12, and after pounding all the rivets for the -9A and -7, I wanted to get in the air quicker.

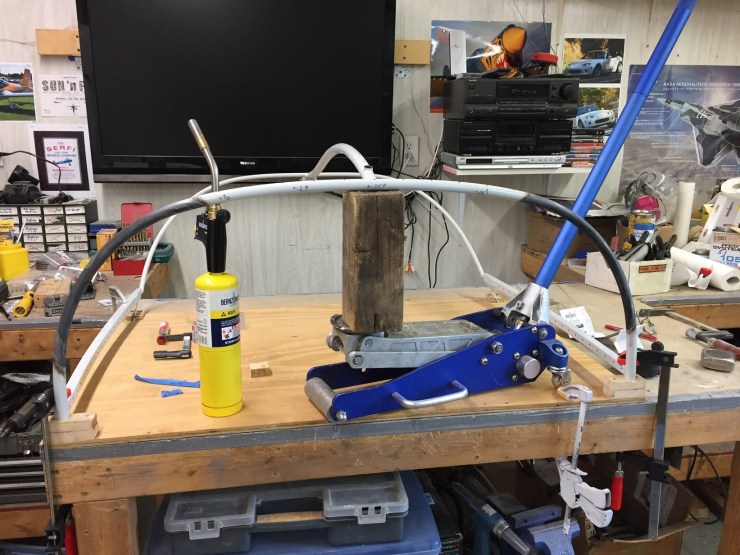

I found my -7A in December in Florida where construction started in 2007 but stopped in 2009. Work past the quick-build stage was well done except for a trial fitting of the canopy. The canopy is a slider, and the frame was never bent inward to align the side tracks and also to make allowance for the canopy wanting to spread the frame outward. Since it was already drilled I had to bend the hoop by heat and pressure from a jack in a holding jig. I was able to align it close enough to use a combination of shims, rivets, and Skyflex to bond the canopy to the frame. After finishing the structures and canopy I installed the tail and wings and did all alignments. I then ordered the finishing kit with a new IO-360 with constant-speed prop and started on the firewall forward, wiring, and instrumentation. Essentially I cloned Van’s dual SkyView panel from my -12 to the -7A but modified it for the -7 panel and structure. There was not enough room for the HDX in the RV-7 panel since the bottom panel lip shielded my panel switches, so I had to buy the last two SkyView Classic Touch panels being shipped from Dynon.

By fall 2018 the wings were completed so I painted them and moved them to the airport. The winter was spent on engine, baffles, cowling, and instrumentation assembly and wiring. In the spring I was ready for paint preparation for the remaining assemblies. I painted the bottom of the aircraft insignia white with the top as modern Cub Yellow in Aero-Thane. The side stripes were put on at the airport in vinyl by a local sign shop.

The inspection was uneventful with airworthiness in June 2018 and first flight in July. The airplane flew perfectly, but my pucker factor was way up. To break in the engine I had to fly circles around the airport at more than 75 percent power for more than an hour on first takeoff. That was not what I wanted to do with an untested airframe, but it was uneventful. The only issue with the airplane was high cylinder head temperatures that limited pattern work. At 10 hours the cause was isolated to a magneto that drifted to about 6 degrees advanced. Once corrected, there have been no problems since.

After visiting Oshkosh 2019 I had 350 hours on the -12, and I put it up for sale. The new owner used it to train for his pilot certificate and commuting. After the sale I could focus on the -7A testing with the 40 hours completed by January 2020. With the pandemic my usual travel events were cancelled so the airplane was just used locally for 2020, and I had a knee replaced so I missed SUN ’n FUN 2021. My first true cross-country was to EAA AirVenture Oshkosh 2021. Two people with camping gear for a week put the airplane at maximum gross. With one fuel/rest stop we saw 152 knots true airspeed at economy 60 percent power, 8,500 feet, and 7.8 gph fuel burn. The airplane met my building objective for capacity, fuel, and cruise speed. Although speed was not my objective, it will easily do more than 170 knots if I want to burn the fuel. My mother said I had to name the airplane so it became Speedy, not that it is especially fast, but it is compared to 115-120 knots for the RV-12. Currently the airplane has 130 hours.

Attention — Aircraft Builders and Restorers

We would love to share your story with your fellow EAA members online and in the pages of EAA Sport Aviation magazine, even if it’s a project that’s been completed for a while. Don’t miss the chance to show off your handiwork and inspire your peers to start or complete projects of their own. Learn more ->